Refractory brick grinding device

A technology for refractory brick grinding and processing, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding workpiece support, etc., which can solve environmental pollution, low efficiency of refractory brick grinding, and health damage of operators and other problems, to achieve the effect of improving the working environment, flexible use, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

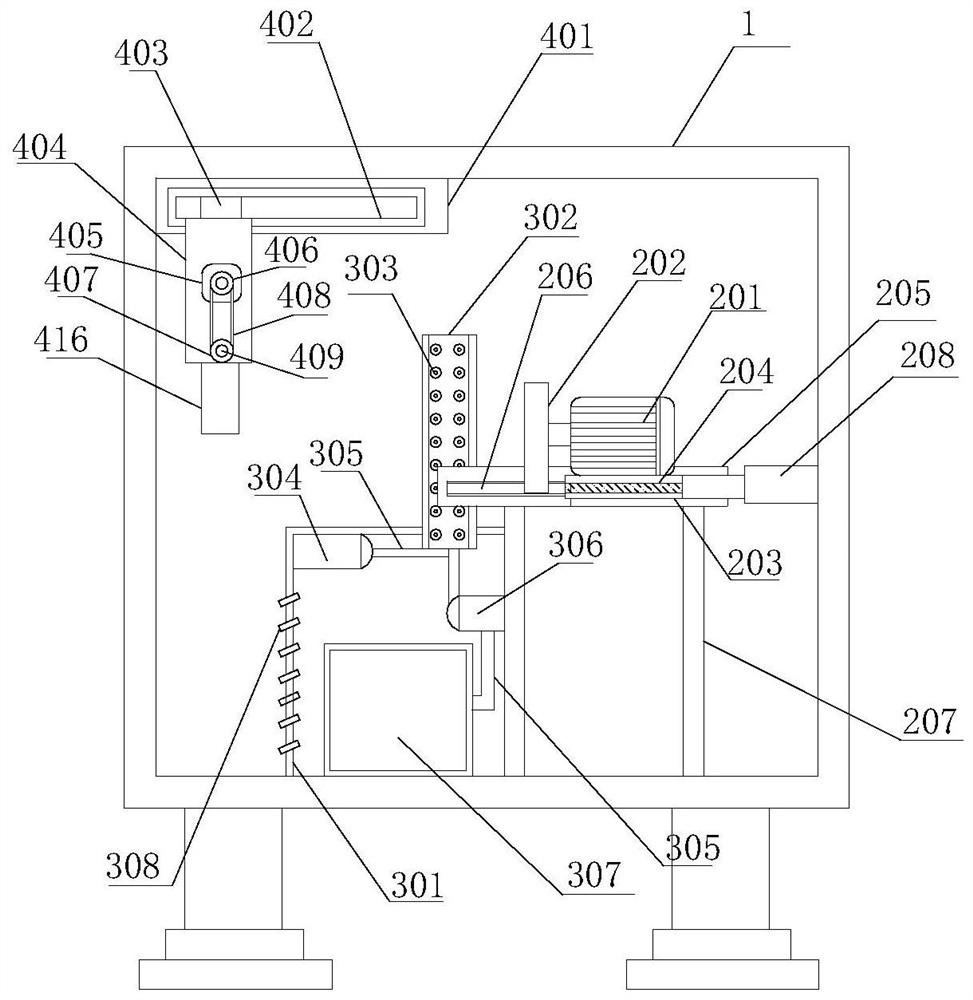

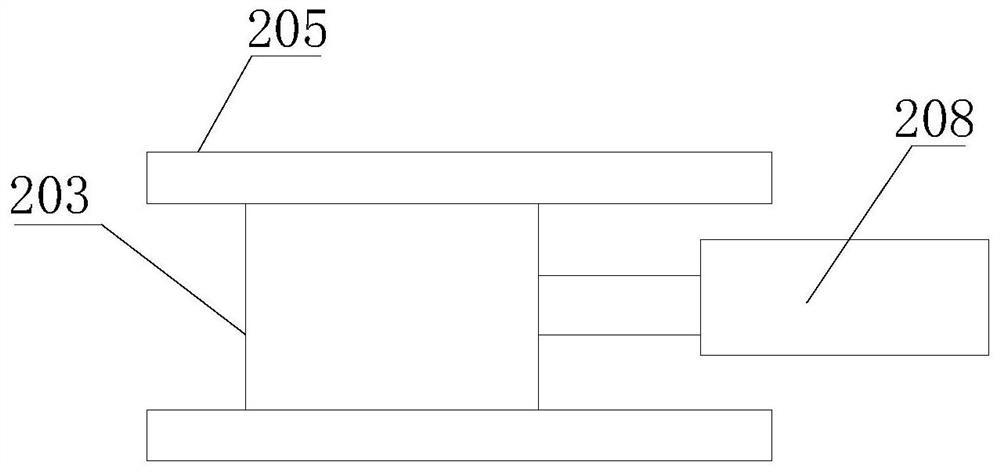

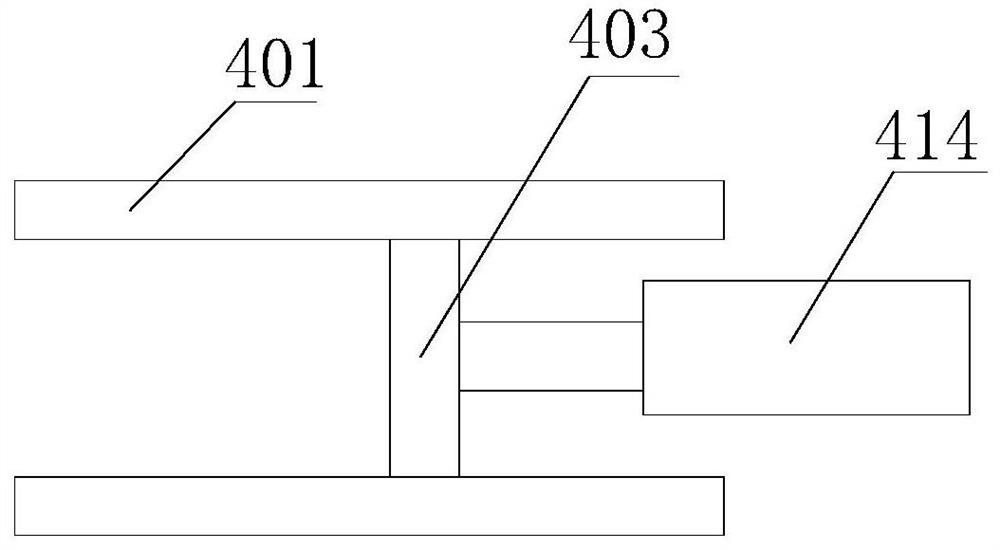

[0022] Such as Figure 1-5As shown, the present invention provides a technical solution: a refractory brick grinding device, including an outer box 1, a grinding mechanism 2 is fixedly installed on the right bottom of the inner cavity of the outer box 1, and the grinding mechanism 2 includes a grinding motor 201, grinding wheel 202, mounting plate 203, bump 204, cross bar-205, bracket-207, electric telescopic rod-208, grinding wheel 202 is socketed on the surface of the output end of grinding motor 201, and the bottom of grinding motor 201 and mounting plate 203 is fixedly connected, and the projection 204 is fixedly installed on the front side and the rear side surface of the mounting plate 203. One side of the cross bar 205 is provided with a chute 206, and the number of the cross bar 205 is two, and the two cross bars One 205 is located on the same horizontal line, and the chute one 206 is arranged on the side where the two cross bars one 205 are close to each other. It is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap