Polishing machine capable of automatically replacing polishing disc

A technology for automatic replacement and polishing of discs, applied in the field of polishing machines, can solve problems such as affecting polishing efficiency and reducing work efficiency, and achieve the effects of improving polishing efficiency, good cooling, and accurate polishing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

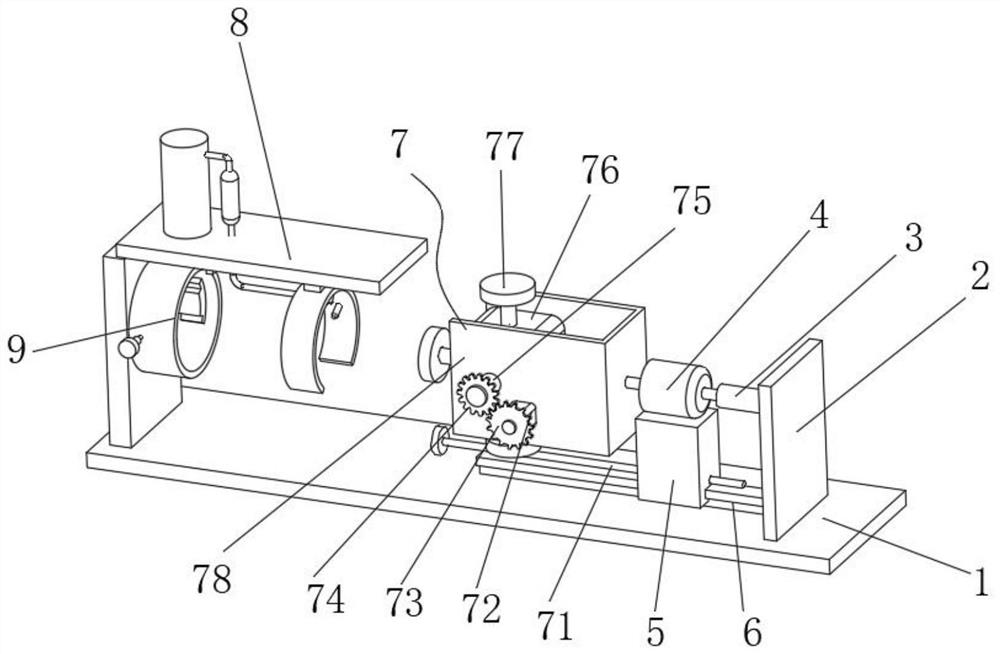

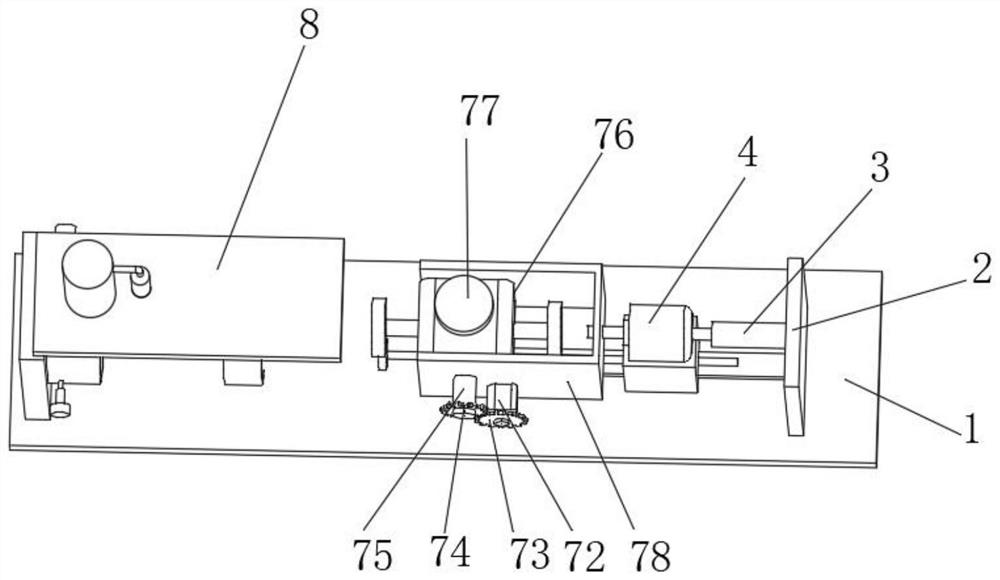

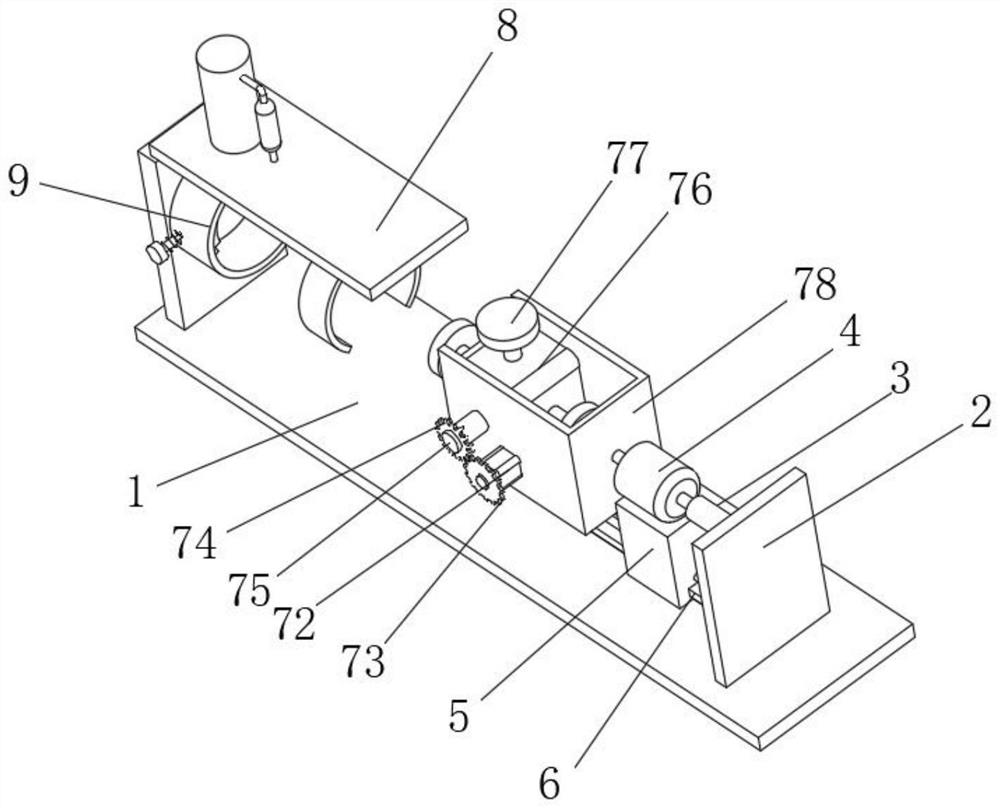

Method used

Image

Examples

Embodiment approach

[0030] As an embodiment of the present invention, the trickle structure 8 includes a support plate 81, a fixed plate 82, a liquid storage tank 83, a diversion bag 84, a valve 85, a sliding buckle 86, a guide rail 87, a limit rod 88, a protective Cover 89, nozzle 810 and contraction spring 811, the bottom side of the support plate 81 is arranged with a guide rail 87, the guide rail 87 is equipped with a slide button 86, and the fixed plate 82 is welded on one end of the guide rail 87, The limiting rod 88 is welded on one side of the fixing plate 82, and one end of the limiting rod 88 is installed inside the sliding buckle 86, and the protective cover 89 is welded on the bottom side of the sliding buckle 86. The nozzles 810 are arranged on the top side of the inner wall of the protective cover 89, the liquid storage tank 83 is fixed on the top side of the support plate 81, the fluid storage tank 83 and the nozzles 810 are connected by a conduit, and a diversion bag is connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com