Phenolated lignin, amphoteric lignin emulsifier, emulsified asphalt and preparation method

A technology of lignin emulsifier and phenolic lignin, applied in chemical instruments and methods, chemical/physical processes, building components, etc., can solve problems such as poor performance and achieve the effect of excellent emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

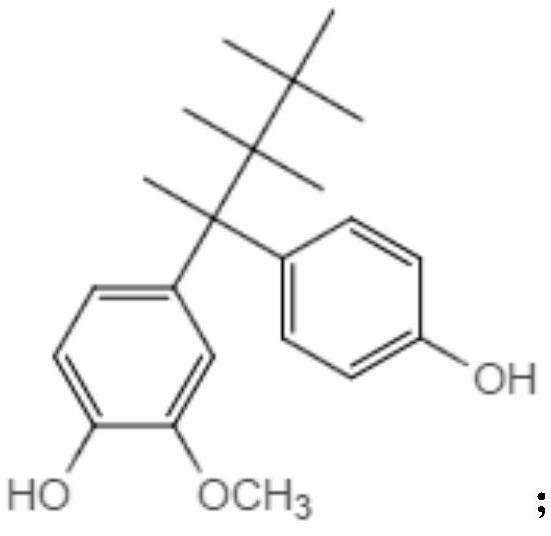

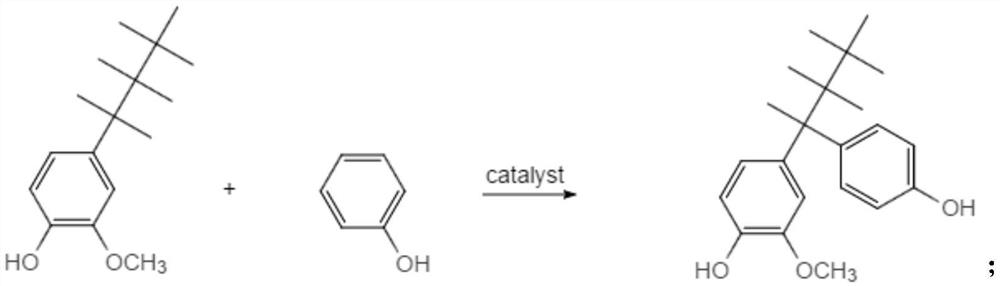

[0038] This preparation example is the phenolized lignin prepared by the preparation method provided in this application.

[0039] Add 50g of deionized water and 50g of lignin into the four-necked bottle, start stirring, raise the temperature to 60°C, adjust the pH to 10 with 30% sodium hydroxide solution, then add 5g of phenol and 1.5g of aluminum chloride, After reacting at 60°C for 1 hour, an aqueous solution of phenolated lignin was obtained, and dried to obtain phenolated lignin-1.

Embodiment 1

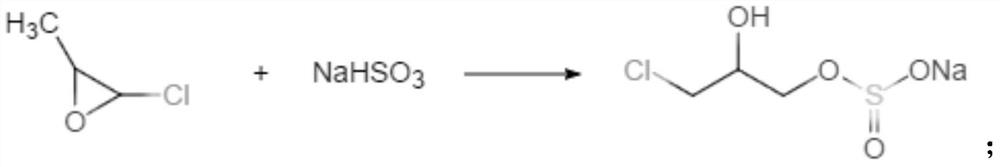

[0046] Weigh 52g of sodium bisulfite, add deionized water to 80g, heat up to 60°C, slowly add 55g of epichlorohydrin dropwise at a rate of 60 drops / min, and react for 2 hours to generate intermediate 1.

[0047] Weigh 140g of the phenolated lignin-1 prepared in Preparation Example 1, add deionized water to 280g, heat up to 60°C, slowly add 30% sodium hydroxide solution to adjust its pH to 10.5±0.2, add 45g of dimethyl Amine, stirred for 15 minutes, then added 40 g of formaldehyde solution with a mass fraction of 37%, raised the temperature to 70° C., and reacted for 4 hours to generate intermediate 2.

[0048] The intermediate 1 and the intermediate 2 were uniformly mixed and reacted at 60° C. for 2 hours to prepare an amphoteric lignin emulsifier.

Embodiment 2

[0050]Weigh 52g of sodium bisulfite, add deionized water to 104g, heat up to 80°C, slowly add 70g of epichlorohydrin dropwise at a rate of 60 drops / min, and react for 1.5 hours to generate intermediate 1.

[0051] Weigh 200g of phenolated lignin-1 prepared in Preparation Example 1, add deionized water to 700g, heat up to 70°C, slowly add 30% sodium hydroxide solution to adjust its pH to 11.0±0.2, add 34g of dimethyl Amine, stirred for 20 minutes, then added 60 g of formaldehyde solution with a mass fraction of 37%, raised the temperature to 80° C., and reacted for 3 hours to generate intermediate 2.

[0052] The intermediate 1 and the intermediate 2 were evenly mixed and reacted at 50° C. for 3 hours to prepare an amphoteric lignin emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com