Coke cake center temperature detection method and system

A core temperature and detection method technology, applied in the field of coking, can solve problems such as the inability to accurately detect the core temperature of coke cake in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

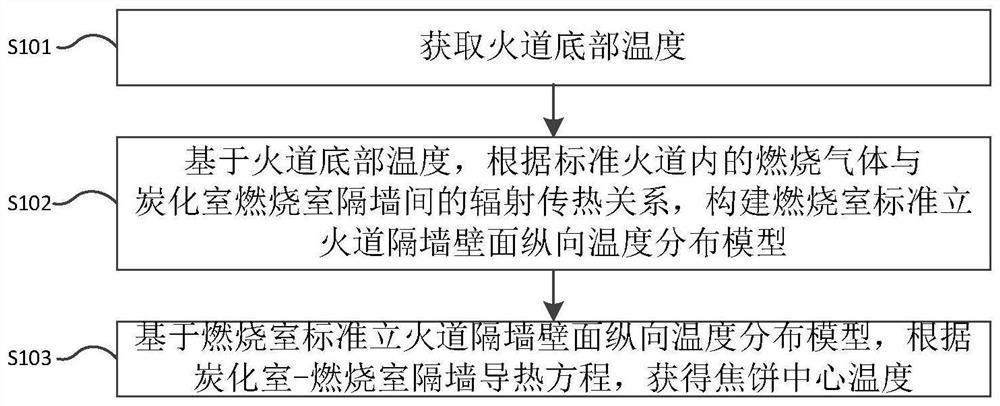

[0056] refer to figure 1 , the coke cake center temperature detection method that the embodiment of the present invention provides, comprises:

[0057] Step S101, obtaining the temperature at the bottom of the flue;

[0058] Step S102, based on the temperature at the bottom of the flue, according to the radiation heat transfer relationship between the combustion gas in the standard flue and the carbonization chamber-combustion chamber partition, construct a longitudinal temperature distribution model on the partition wall of the standard vertical flue in the combustion chamber;

[0059] Step S103, based on the longitudinal temperature distribution model of the combustion chamber standard flue partition wall surface, and according to the carbonization chamber-combustion chamber partition wall heat conduction equation, the coke cake center temperature is obtained.

[0060] The coke cake center temperature detection method provided by the embodiment of the present invention, by ...

Embodiment 2

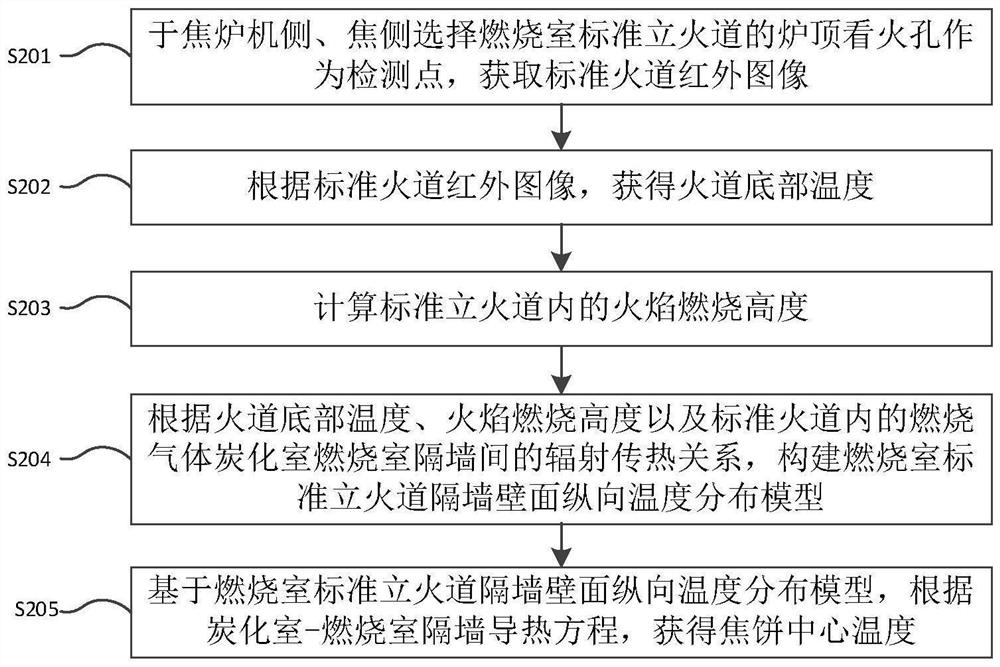

[0066] refer to figure 2 , the coke cake center temperature detection method provided by Embodiment 2 of the present invention, comprising:

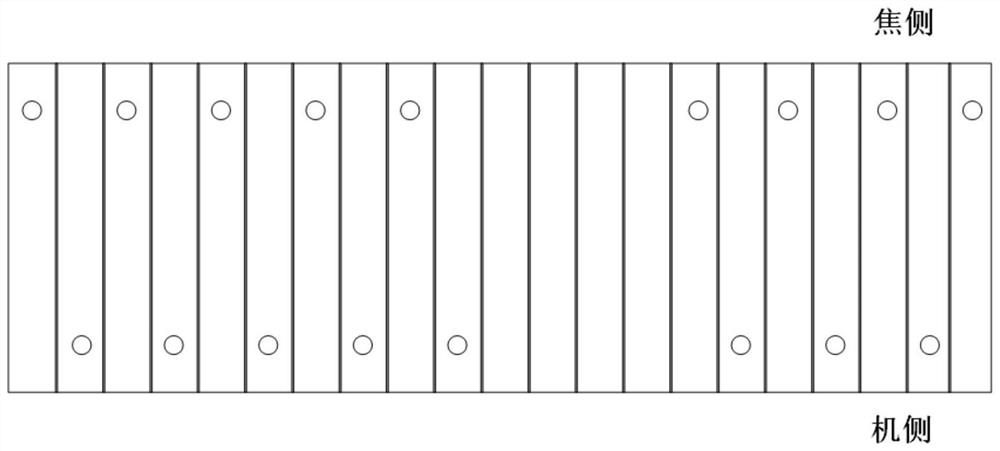

[0067] Step S201, select the fire viewing hole on the top of the standard vertical flue of the combustion chamber as the detection point on the coke oven machine side and the coke side, and acquire the infrared image of the viewing hole including the bottom area of the standard flue.

[0068] In step S202, the temperature at the bottom of the fire path is obtained by looking at the infrared image of the fire hole according to the standard fire path.

[0069] Specifically, the embodiment of the present invention proposes a detection idea different from previous methods based on the coupling relationship between the center temperature of the coke cake and other production parameters. Specific steps are as follows:

[0070] Step1: Determine the coupling variable of the core temperature of the coke cake:

[0071] The production process...

Embodiment 3

[0236] The specific embodiment of the present invention will be further described below in conjunction with specific examples. In Example 3, a JN60 coke oven of a steel plant is used as an experimental platform, and the proposed detection method is applied to the detection of the temperature of the coke cake center. This case obtained the production data of the JN60 coke oven of the plant from June 2019 to September 2019, including the measured temperature on the machine side and the coke side, coking time, flue suction, air excess coefficient, coke oven gas flow, blast furnace gas flow. These data can be used to verify the test results.

[0237] Since the current main detection method of coke cake center temperature is still the "intubation method", there is a lack of other efficient detection methods, and it is limited by the detection cost and detection cycle, as well as the coke pushing sequence, furnace maintenance, etc. Due to the consideration of the coke oven producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com