Mine drilling exhaust pipe traction non-return device

A gas extraction pipe and backstop technology, which is applied in the direction of drill pipes, safety devices, drill pipes, etc., can solve the problems that it is difficult to realize the interconnection between the bottom of the mine and the gas extraction device, it is difficult to reach the bottom of the borehole, and the gas extraction is unfavorable. , to achieve the effect of convenient production and installation, good cooperation, and smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

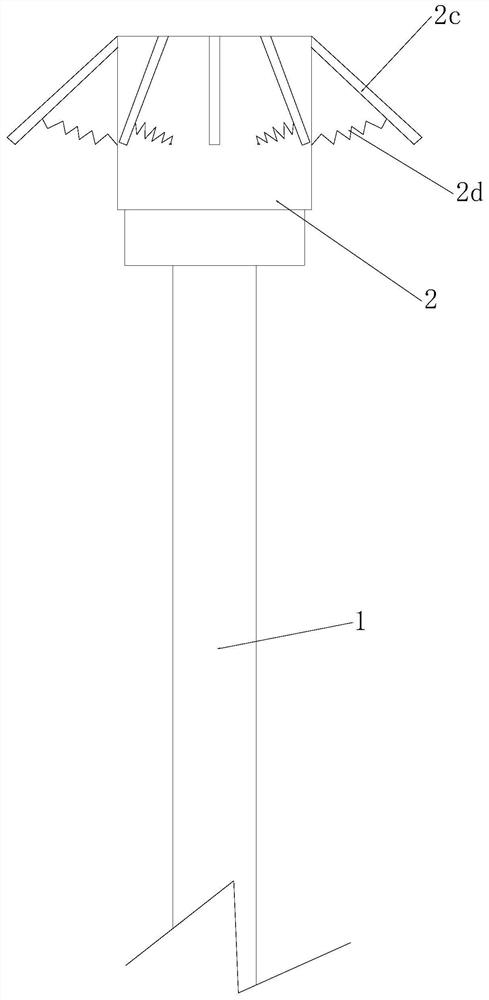

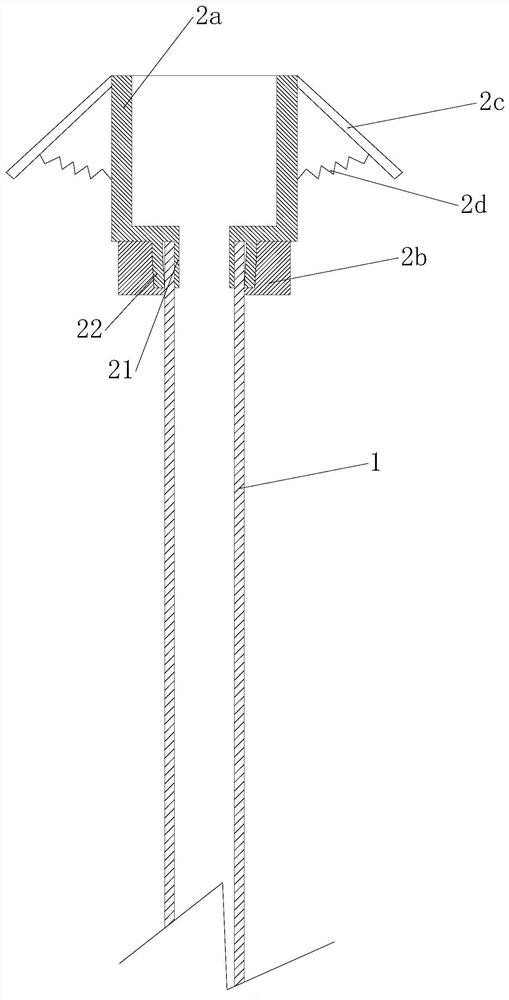

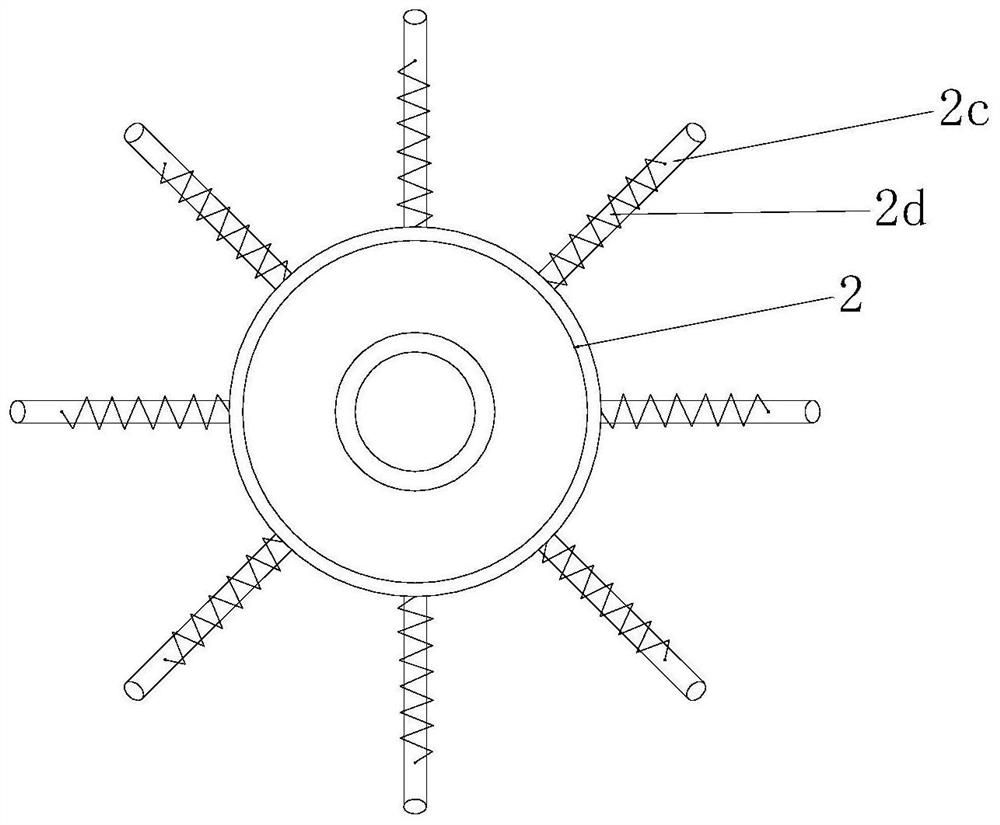

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 sectional view of image 3 for figure 1 The bottom view of the bottom view, as shown in the figure, the mine drilling air extraction pipe traction backstop device in this embodiment includes a backstop thrust head 2 detachably installed at the end of the air extraction pipe 1, and the backstop thrust head 2 includes The main body 2a and the fastening sleeve 2b, the main body 2a communicates with the exhaust pipe 1, the fastening sleeve 2b is used to assist the tight connection between the main body 2a and the end of the exhaust pipe 1, and the reverse thrust head 2 includes a connecting component and backstop components.

[0021] In this embodiment, the connecting assembly includes a clamping part arranged on the body 2a and a fastening sleeve 2b sleeved on the outer end of the exhaust pipe 1, the fastening sleeve 2b is threadedly connected with the clamping part, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com