Paraffin removal device for oil field and using method thereof

A wax removal and oilfield technology, applied in cleaning equipment, earthwork drilling, wellbore/well parts, etc., can solve the problem that the wax removal device cannot be applied to oil wells, etc., and achieve the effect of high wax removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

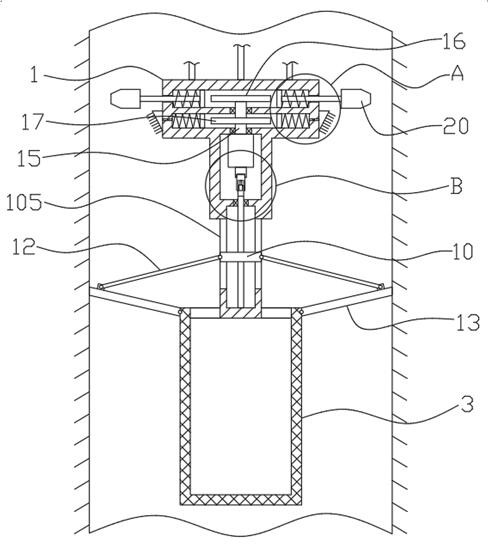

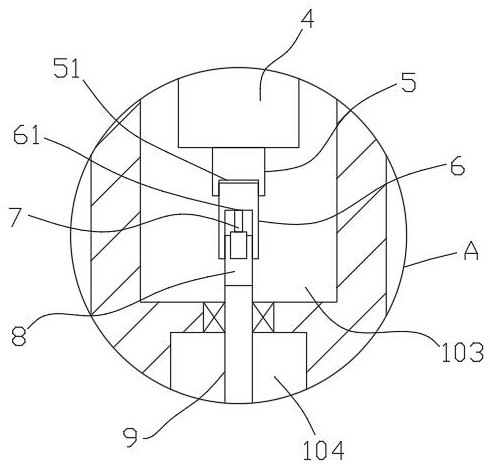

[0027] refer to Figure 1-5 , a wax removal device for oilfields, comprising a device body 1 integrally formed by three cylinders whose diameters successively decrease from top to bottom, and a first rotating chamber 101, a second rotating chamber 101, and a The rotating cavity 102, the third rotating cavity 103 and the fourth rotating cavity 104, the outer wall of the lower end of the device body 1 is uniformly fixedly connected with a plurality of connecting rods 2 in the circumferential direction, and the ends of the plurality of connecting rods 2 away from the device body 1 are jointly fixedly connected with leaks. The cylinder 3 and the inner top wall of the third rotating cavity 103 are fixedly installed with a biaxial motor 4, and the upper and lower output ends of the biaxial motor 4 are respectively fixedly connected with an upper drive shaft 15 and a lower drive shaft 5, and the upper end of the upper drive shaft 15 runs through The second rotating chamber 102 extend...

Embodiment 2

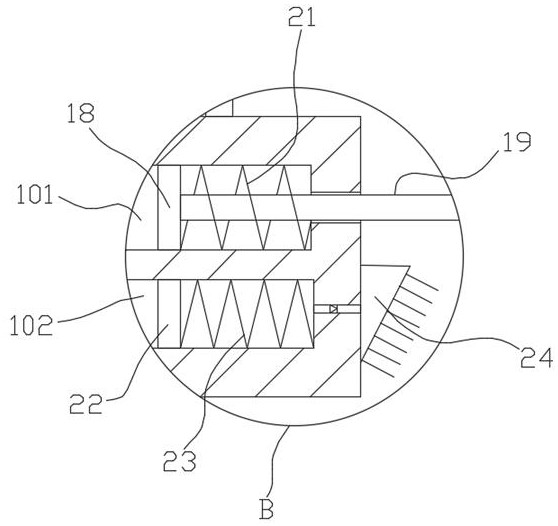

[0031] It is basically the same as Embodiment 1, except that the softening mechanism includes a second cam 17 fixedly sleeved on the upper drive shaft 15, and a plurality of second sliding plates 22 are uniformly slidably connected in the circumferential direction of the second rotating chamber 102. The side of the second slide plate 22 far away from the second cam 17 and the inner wall of the second rotating chamber 102 are fixedly connected with a sealed elastic bag 23, the elastic bag 23 is an air bag with elastic recovery ability, and utilizes the extrusion of the second cam 17 and its own recovery ability, can suck or extract hot water, the second rotating chamber 102 is embedded with a one-way water outlet pipe communicating with the elastic bag 23, the other end of the one-way water outlet pipe is connected with a nozzle 24, and the elastic bag 23 passes through the one-way water outlet pipe. The water pipe is connected with a hot water tank, and the above-mentioned one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com