Electromagnetic heating and ball collecting device for oil pipeline and heating and ball collecting method of electromagnetic heating and ball collecting device

An oil pipeline and oil outlet pipeline technology, which is applied in the field of electromagnetic heating ball collecting devices for oil pipelines, can solve the problems of inability to meet the development needs of intelligent oil fields, waste of crude oil and wax remover, damage to enameled wire insulation, etc., and is beneficial to environmental protection. , The effect of improving the ball collection efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

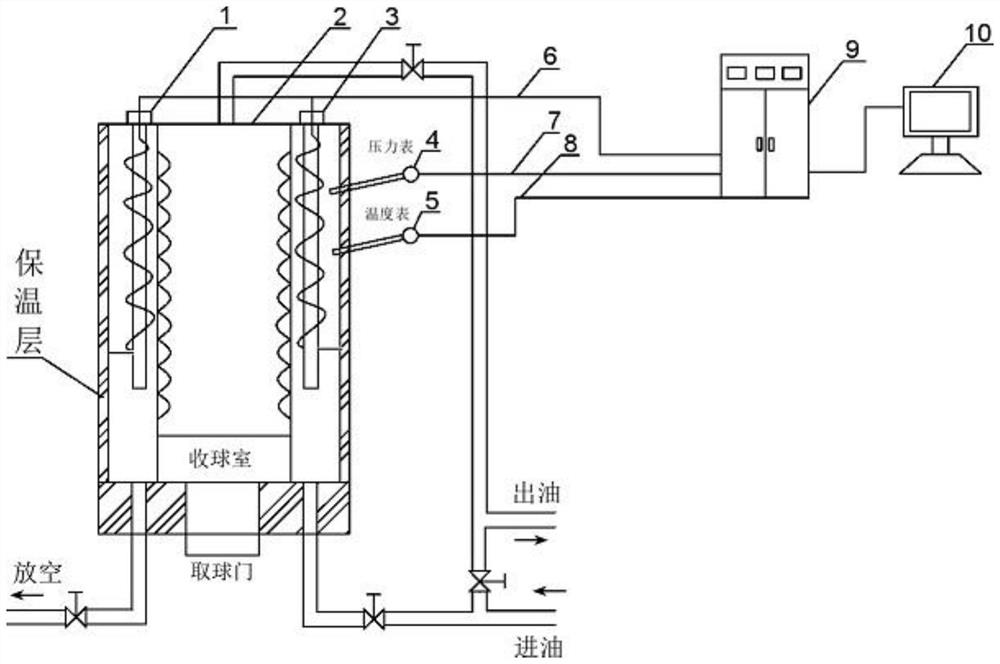

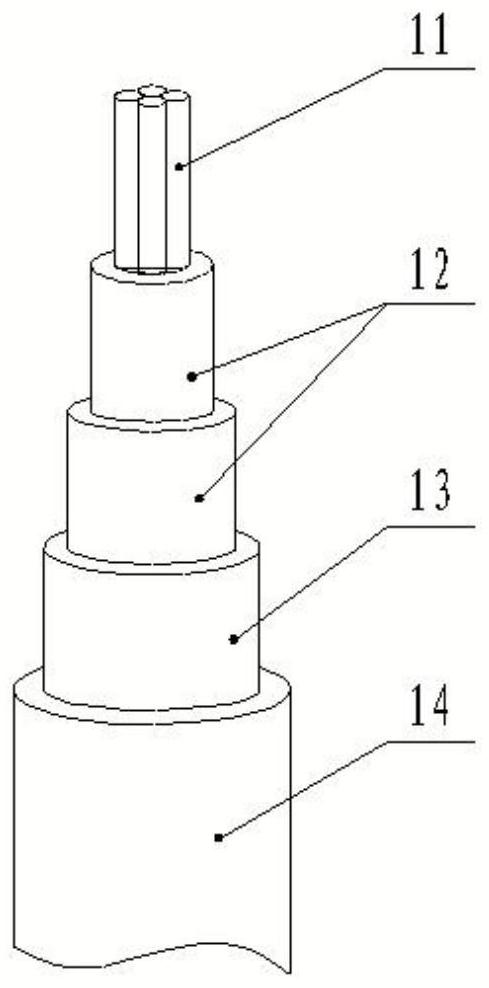

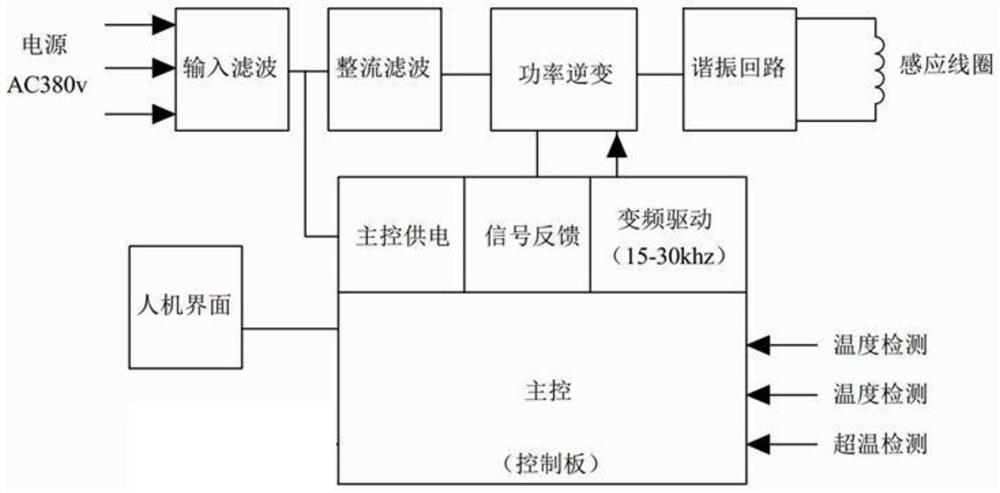

[0040] refer to Figure 1-Figure 3 The shown electromagnetic heating ball collecting device for oil pipeline includes a ball collecting mechanism 2, an electromagnetic heating control mechanism 9, an electromagnetic heating mechanism, an intelligent monitoring mechanism and a remote controller 10; It is connected with the oil inlet pipeline and the oil outlet pipeline. The bottom end of the ball collection mechanism 2 is connected with the oil inlet pipeline through the pipeline. The bottom end of the ball collection mechanism 2 is also provided with a venting pipeline. There are pipeline control switches in the space, between the oil outlet pipeline and the oil inlet pipeline, between the oil inlet pipeline and the bottom end of the ball collecting mechanism 2 and on the emptying pipeline, and the pipeline control switch is connected with the electromagnetic heating control mechanism 9 by electrical signals; The electromagnetic heating mechanism is fixedly connected in the ba...

Embodiment 2

[0044] refer to figure 1 The shown electromagnetic heating ball collecting device for oil pipeline, on the basis of the first embodiment, the ball collecting mechanism 2 at least includes an inner hollow cylinder cast by high pressure steel; The separator, each separator is evenly provided with through holes, and the diameter of the through holes is smaller than the diameter of the wax balls received; an electromagnetic heating mechanism is arranged between each separator and the inner side wall of the cylinder; the center of the bottom surface of the cylinder is provided with an electromagnetic heating mechanism. A ball-taking port is provided, and a ball-taking gate is arranged on the ball-taking port.

[0045] In a specific application, the ball collecting mechanism 2 is essentially a barrel-shaped structure cast by high pressure steel. The arrangement of the partition can effectively prevent the wax ball from passing through, and effectively avoid the wax ball hitting the...

Embodiment 3

[0049] refer to figure 1 In the shown electromagnetic heating ball collecting device for oil pipeline, on the basis of the second embodiment, the inner and outer side walls and the lower end surface of the cylinder are provided with thermal insulation layers.

[0050] In specific applications, the setting of the thermal insulation layer makes the heating effect better and saves energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com