Method for inhibiting influence of non-uniformity of optical material in large-aperture interferometer

An optical material, non-uniformity technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve problems such as inapplicability, inability to pre-select the best material parts, etc., to achieve strong practicability, simplicity, flexibility and easy modification and processing. low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

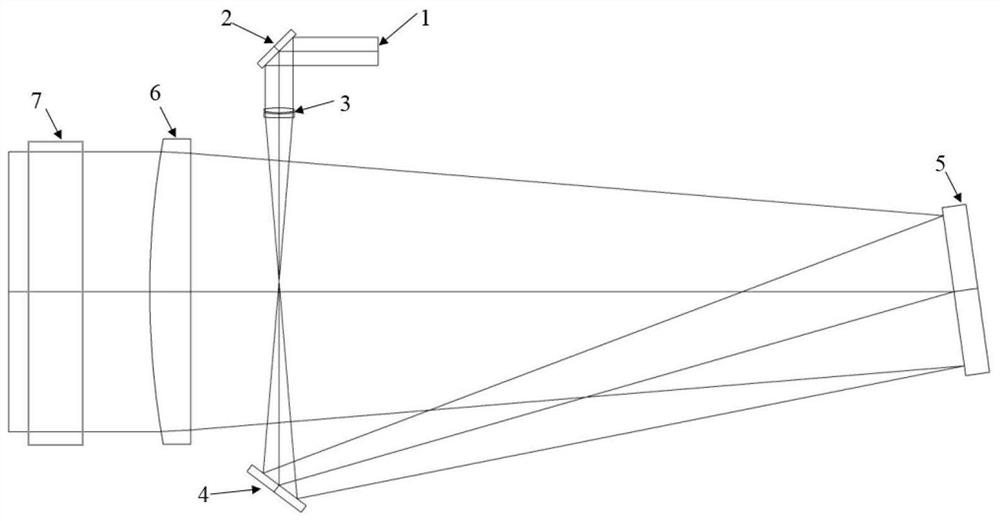

[0034] combine figure 1 The large-aperture interferometer shown includes a large-aperture interferometer beam expander system and a small-port wavefront exit module, and the large-aperture interferometer beam expander system includes a first reflector 2, a small-aperture collimator 3, and a second reflector 4 , the third reflector 5, a large-diameter collimator mirror 6 and a TF standard flat plate 7; the small-port wavefront exit module produces a small-diameter collimated wavefront 1, and the small-diameter collimated wavefront 1 is folded and reflected by the first reflector 2 and then The beam expands to the second reflector 4 through the small-diameter collimator 3, folds and reflects to the large-diameter collimator 6 through the second reflector 4 and the third reflector 5, and becomes collimated after passing through the large-diameter collimator 6 The light is collimated and emitted. After the collimated light passes through the TF standard plate 7, a part of the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com