Antifouling coating

A surface coating and composition technology, applied in the field of generating such antifouling coatings, can solve problems such as low mechanical stability, and achieve the effects of high mechanical stability, improved long-term stability, and good antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

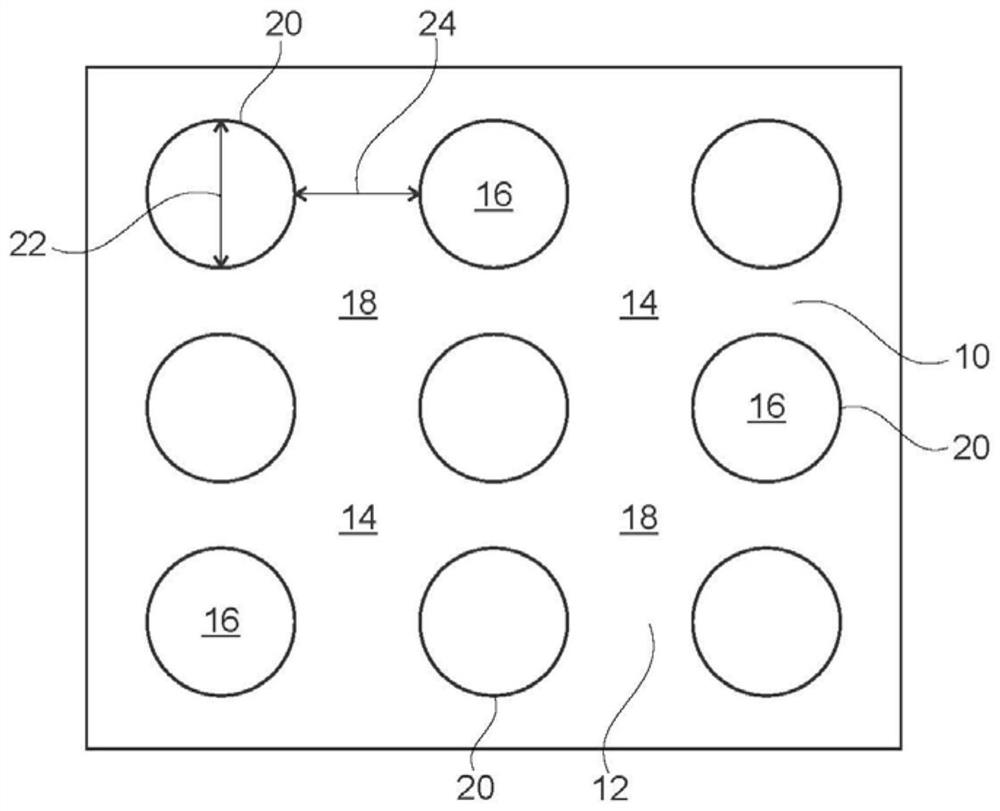

[0145] figure 1 A top view of the surface coating 10 is shown. The surface coating 10 is particularly useful for parts in aquatic applications, for example as an antifouling coating.

[0146] It can be seen that the surface coating 10 has a composition 12 which is separately formed or has a polymer structure. The polymer structure consists of three, ie at least three, units. where the first unit, not shown, comprises a polyamidoamine-based dendrimer structure, wherein the second unit 14 comprises an epoxy resin, and wherein the third unit 16 comprises an amine-reactive polysiloxane, in such a manner as To construct the polymer structure: the first unit is formed as a central unit to which each of the second unit 14 and the third unit 16 is covalently bonded.

[0147] in this regard, figure 1 A matrix 18 of epoxy resin of the second unit 16 is shown, in which there is a domain 20 of polysiloxane (eg, polydimethylsiloxane) of the third unit, which is connected to the ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com