Iron core raw material fixed-length feeding device based on ferrite magnetic core cutting machining

A ferrite core and cutting processing technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing, etc., can solve the problems of inability to complete production work with high efficiency and consume manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

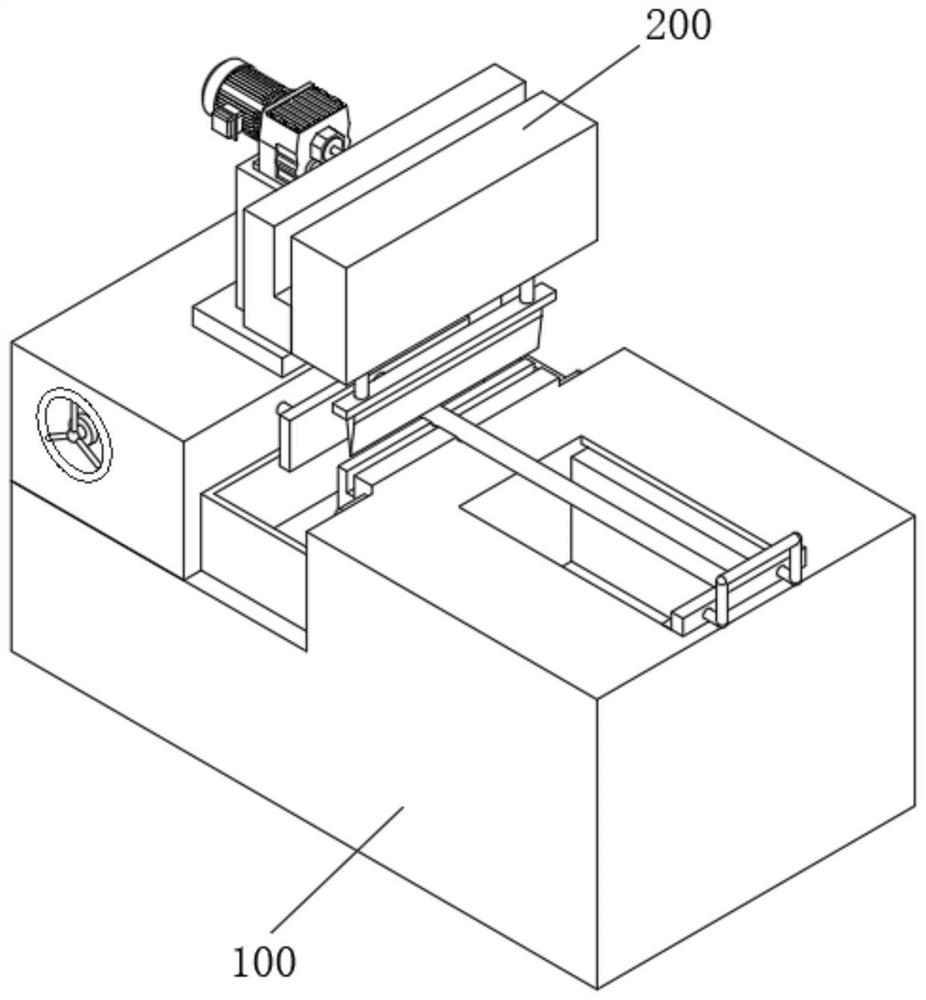

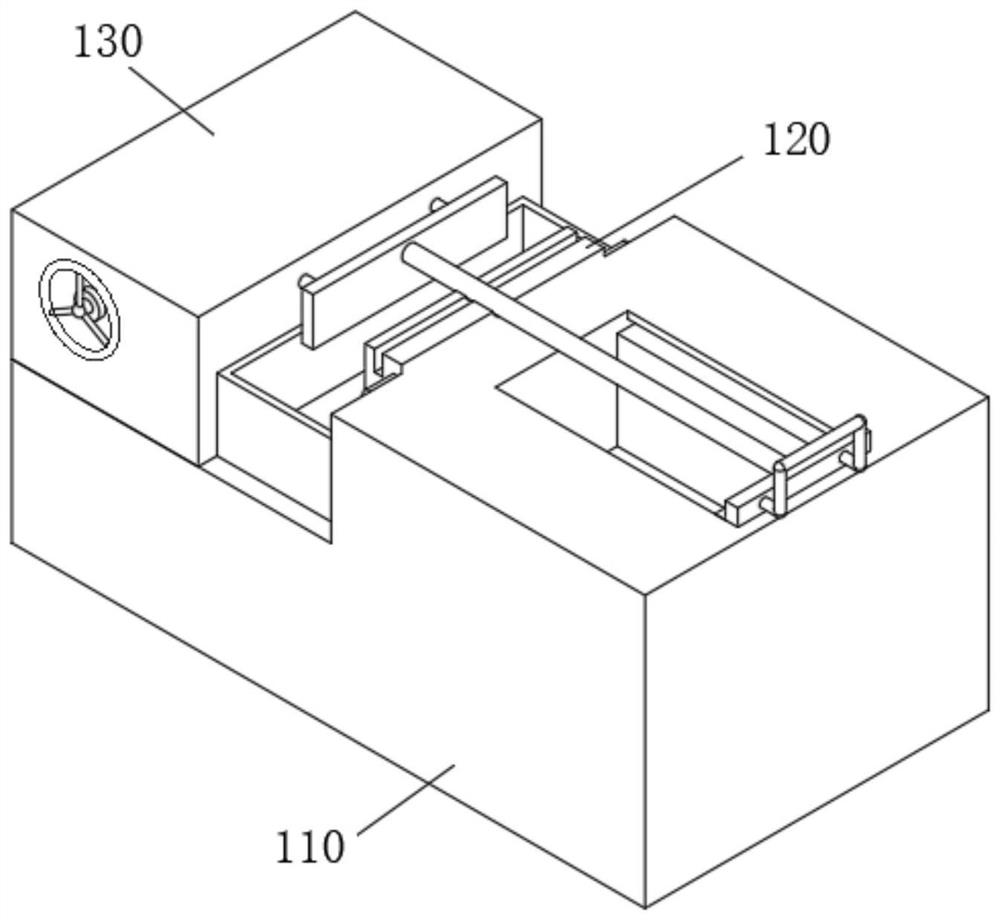

[0058] see Figure 1-Figure 16 As shown, this embodiment provides a fixed-length feeding device for iron core raw materials based on ferrite core cutting, including a feeding device 100 and a cutting device 200 installed above the feeding device 100, the cutting device 200 includes a cutting box 210, A cutter 211 is connected to the bottom of the cutting box 210, and the feeding device 100 includes at least:

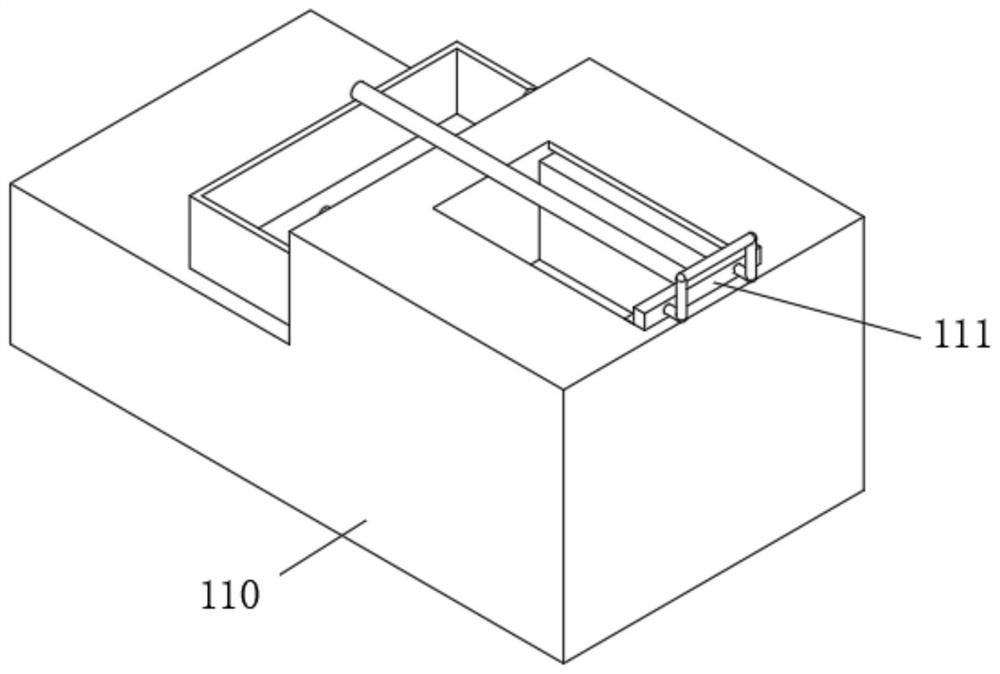

[0059] The base 110, the upper surface of the base 110 is provided with a feeding chamber 1100, the feeding chamber 1100 is internally connected with a feeding plate 111, the upper surface of the rear end of the base 110 is placed with a magnetic core body 112, the front end of the feeding plate 111 is provided with a bottom plate 1110, and the magnetic core body 112 The bottom end of the feeding chamber 1100 is in contact with the front surface of the feeding plate 111, and is located above the bottom plate 1110, which is convenient for supporting the magnetic core body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com