Regenerated fly ash ceramsite production method

A technology of fly ash ceramsite and production method, which is applied in the field of building base material production, can solve the problems of high production cost, inability to transport materials well, increase active adsorption centers of fly ash ceramsite, etc., so as to improve strength and Toughness, improving the effect of stirring and mixing, and improving the effect of mixing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

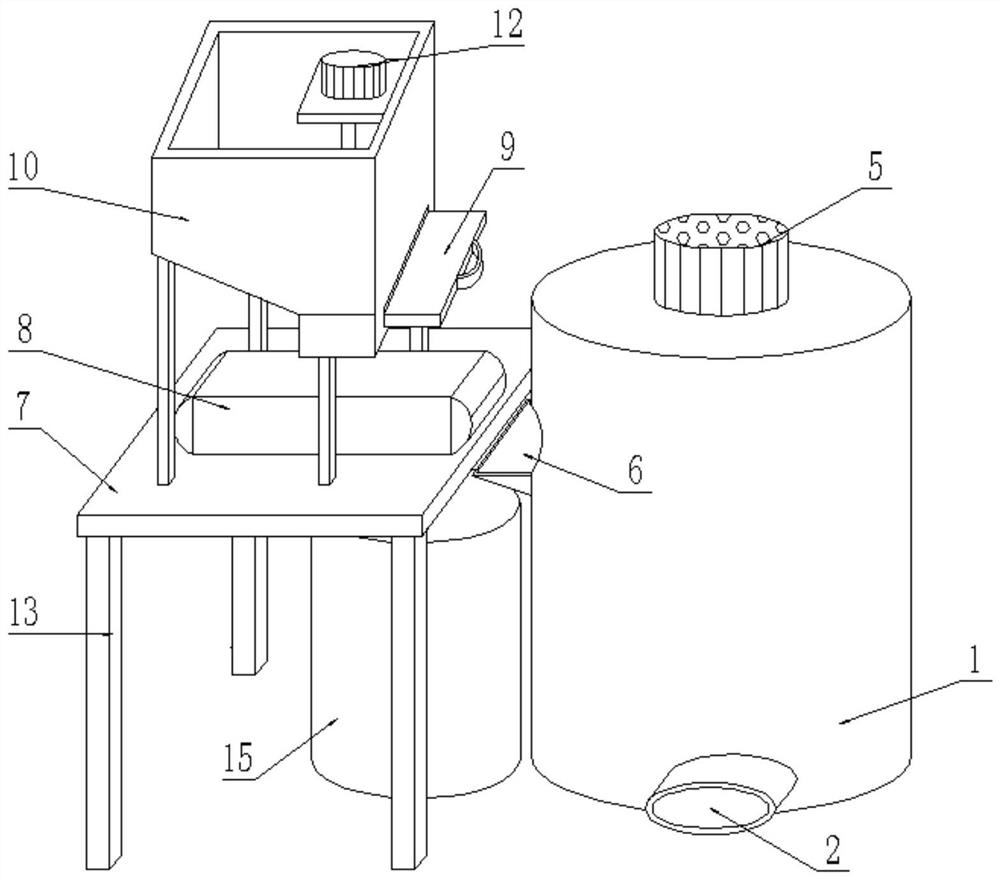

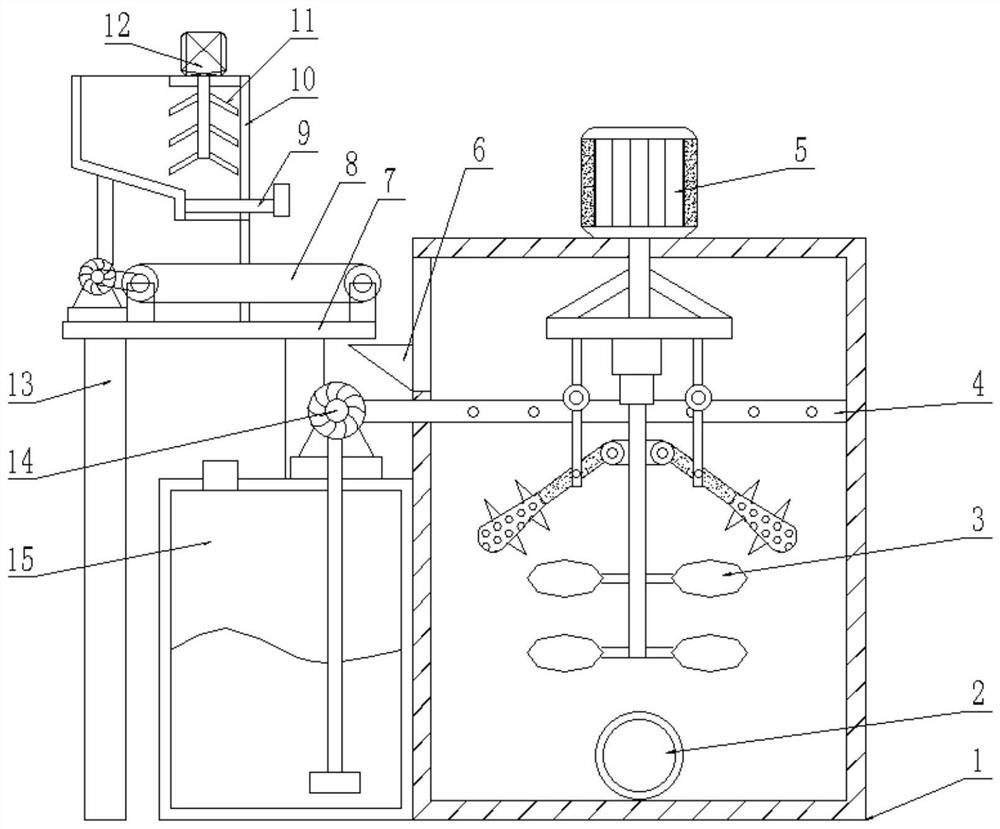

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

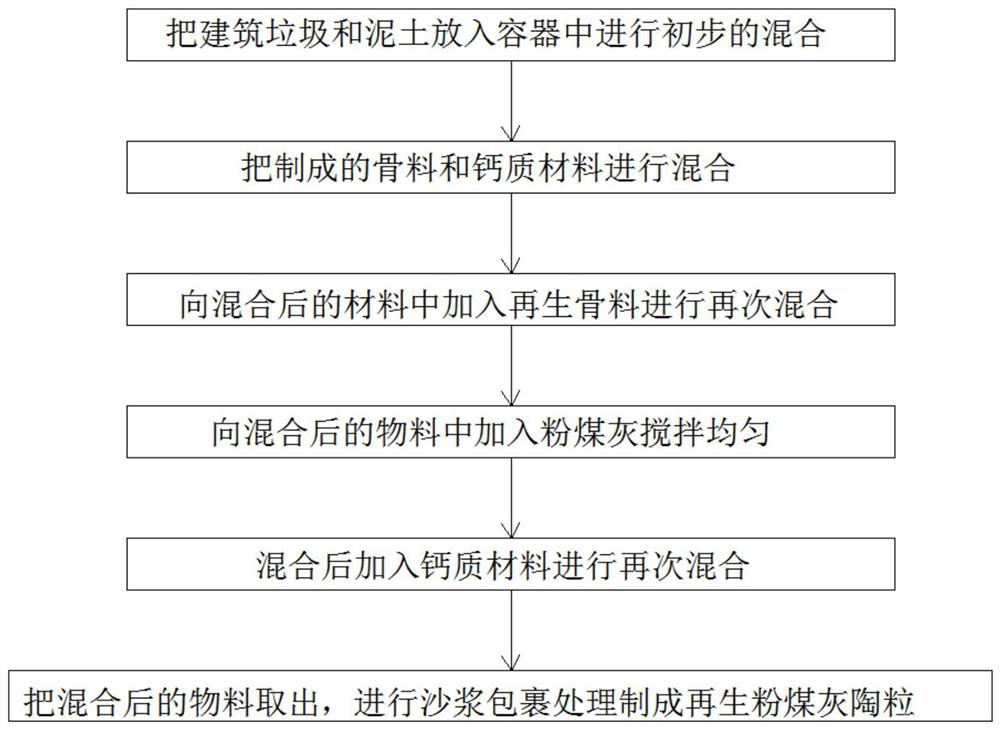

[0031] refer to figure 1 , a method for producing recycled fly ash ceramsite, comprising the following steps:

[0032] S1: Put the construction waste and soil into the container for preliminary mixing. The mixing ratio of construction waste and aggregate is 1:1.

[0033] S2: Mixing the produced aggregate with calcareous material.

[0034] S3: Add recycled aggregate to the mixed material for re-mixing, the mixing ratio is 1:(0.3-0.5).

[0035] S4: Add fly ash to the mixed material and stir evenly.

[0036] S5: After mixing, add the calcareous material and mix again.

[0037] S6: Take out the mixed materials and wrap them in mortar to prepare recycled fly ash ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com