Drying device for chemical fertilizer

A drying device and fertilizer technology, applied in the directions of drying, drying machine, heating device, etc., can solve the problems of poor drying effect, difficult drying of chemical fertilizers, low efficiency, etc., so as to improve drying effect, improve efficiency, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

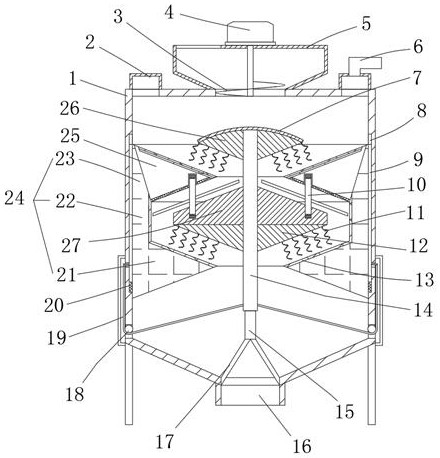

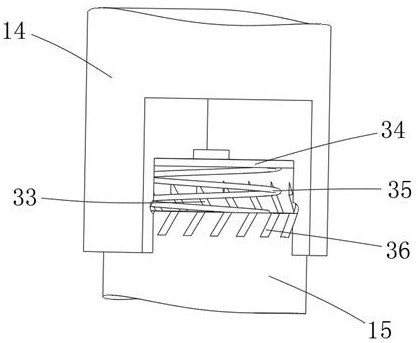

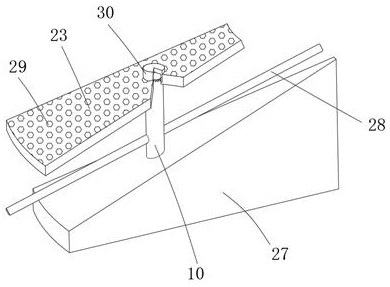

[0025] refer to Figure 1-4 , a drying device for chemical fertilizers, comprising a cylinder 1, the top of the cylinder 1 is provided with a feeding mechanism, and the top outer wall of the cylinder 1 is fixedly connected with an exhaust shell 2 communicating with the cylinder 1, the exhaust shell 2 The top outer wall is fixedly connected with the exhaust pipe 6, the bottom outer wall of the cylinder body 1 is provided with a discharge port 16, and a fixed rod 15 is provided directly above the discharge port 16, and the bottom outer wall of the fixed rod 15 is connected to the cylinder through a support rod 17. The side inner wall of the body 1, the top of the fixed rod 15 is provided with a core rod 14, and the bottom end of the core rod 14 is provided with a cylindrical groove, the fixed rod 15 is slidably connected to the side inner wall of the cylindrical groove, and the side inner wall of the cylindrical groove is provided with a threaded groove 33, the top of the side o...

Embodiment 2

[0035] refer to Figure 5 , a drying device for chemical fertilizers. Compared with Embodiment 1, the top outer wall of the material distribution plate 7 is fixedly connected with a collecting ring 31, and the bottom of the side outer wall of the collecting ring 31 is provided with evenly distributed feeding troughs. Mouth 32.

[0036] When the present invention is in use: compared with Embodiment 1, when the blanking falls on the material distribution plate 7, it will first fall into the collection ring 31, and then fall from the blanking notch 32 on the side of the collection ring 31, thereby preventing fertilizer Unable to fall to the middle position of the material distribution plate 7 and cause the material falling from the surroundings of the material distribution plate 7 to be uneven, so that the material blanking is more uniform.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap