Large-gradient temperature field generating device for controlling alkali metal distribution in atomic gas chamber

An atomic gas chamber and gradient temperature technology, which is applied in the direction of temperature control by electric means, auxiliary controller with auxiliary heating device, etc., can solve the problems of difficult operation, poor controllability, complex structure, etc., and improve the measurement accuracy. , improve stability, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with embodiment.

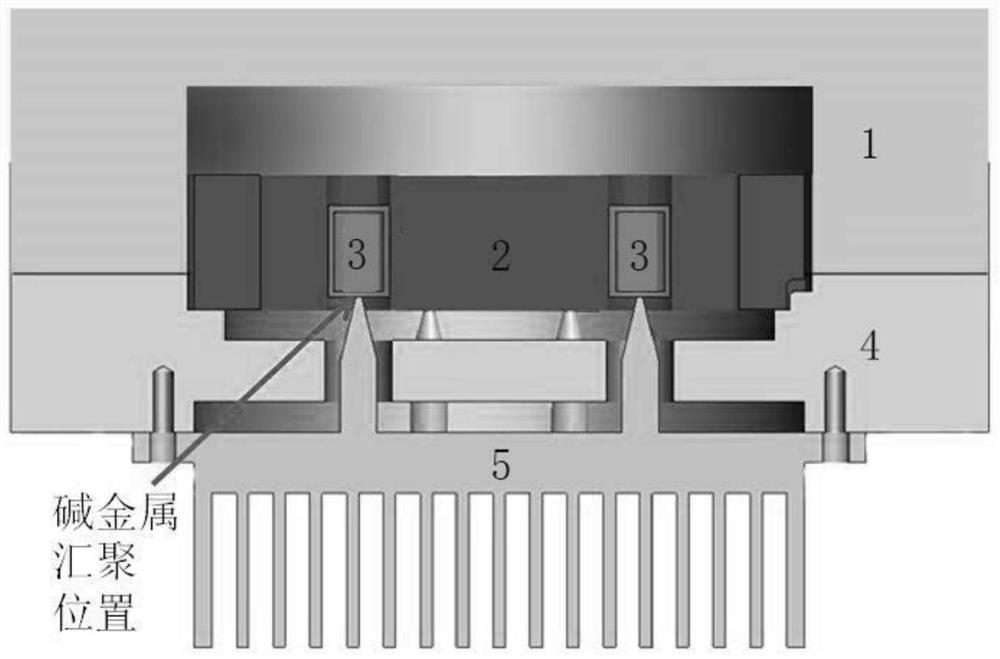

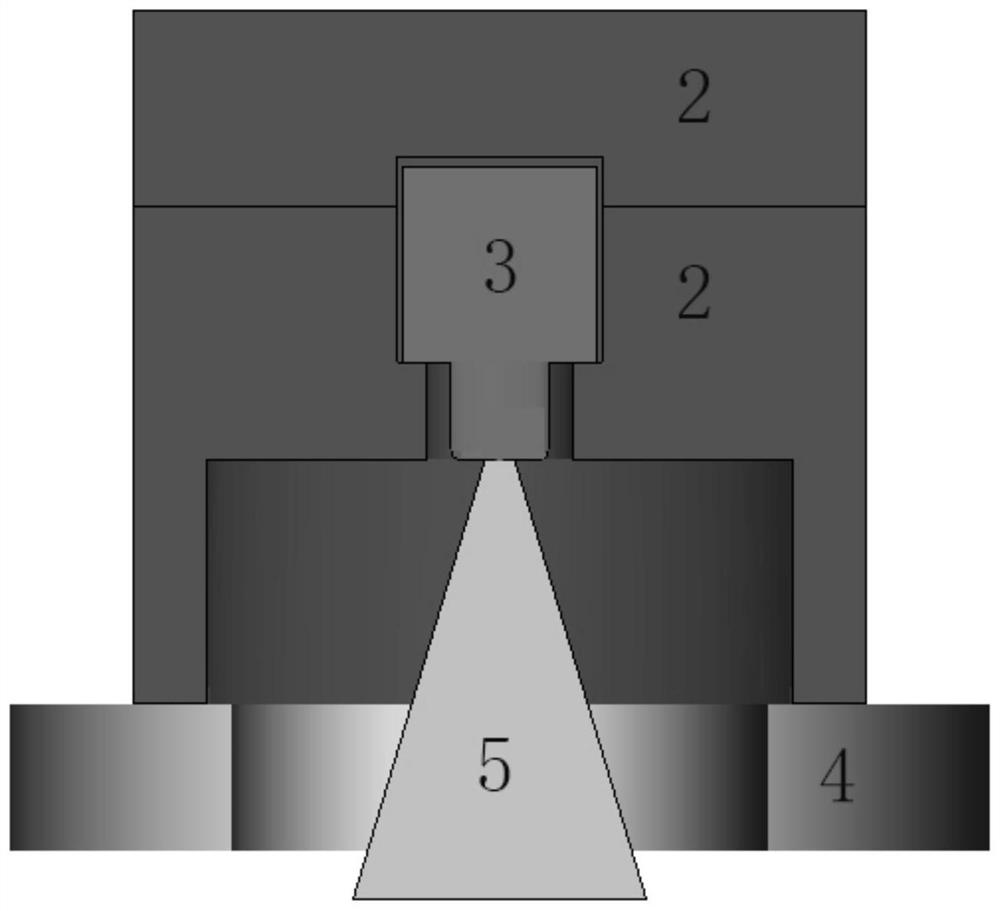

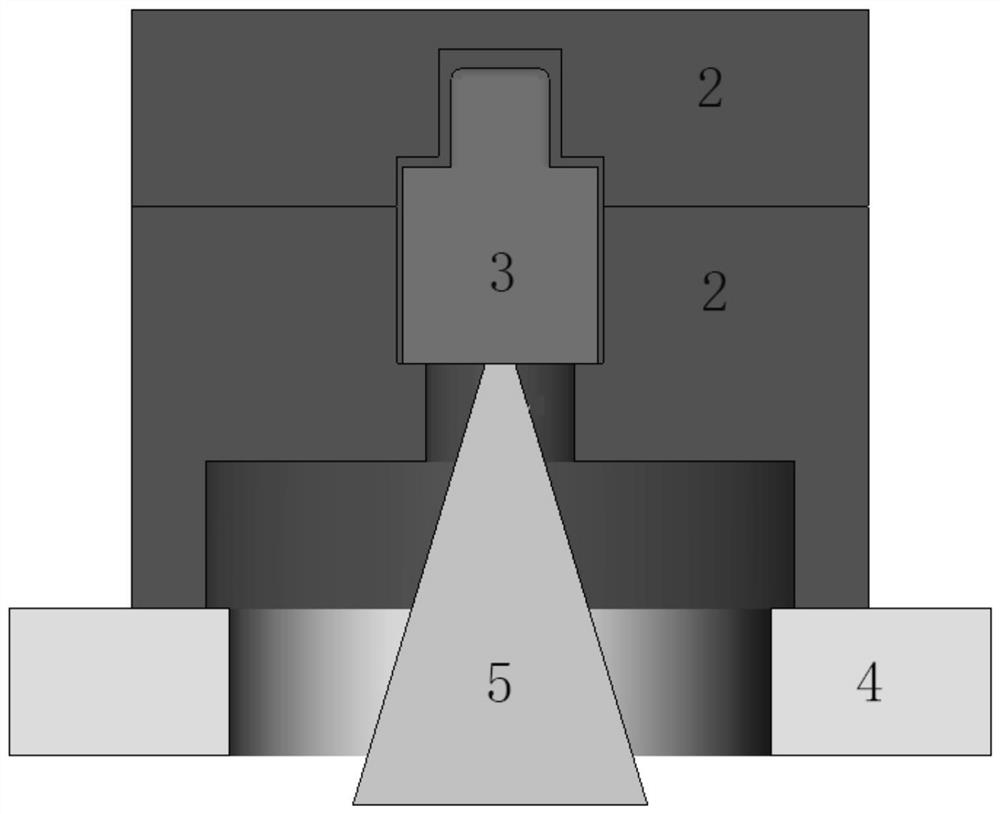

[0028] like figure 1 As shown, a large gradient temperature field generating device for controlling the distribution of alkali metals in an atomic gas chamber includes a hot end 1, an atomic gas chamber placer 2, an atomic gas chamber 3, a thermal insulation pad 4, and a cold end 5;

[0029] The temperature rise of the hot end 1 is controlled by a heating jacket, and the temperature of the atomic gas chamber placer 2 is raised through heat radiation to ensure that the temperature in the atomic gas chamber 3 is higher than the melting point of the alkali metal. The temperature of hot end 1 needs to be lower than 200°C. An atomic gas chamber 3 is installed in the atomic gas chamber placer 2 , and a thermal insulation pad 4 is arranged between the atomic gas chamber placer 2 and the cold end 5 .

[0030] The atomic gas chamber placer 2 can be selected as a single or batch processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com