Laser forming method for TiC-FeCr-Gr composite material component

A laser forming and laser head technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of uneven distribution of reinforcement phases, reducing the performance of graphite TiC-FeCr-Gr composite parts, and changing the design components of reinforcement phases. , to achieve the effect of eliminating the uneven distribution of the enhanced phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A TiC-FeCr-Gr composite material annealing furnace roll laser forming method, comprising the following processes:

[0021] (1) Raw material formula and pretreatment

[0022] The raw material formula is: graphite 0.91wt.%, Ti5.88wt.%, Cr23.21wt.%, rare earth oxide 0.33wt.%, Fe balance; the raw material is in powder form, and the particle size of metal powder and graphite powder is 60 microns; Metal Ti powder and mixed rare earth powder were ball milled together for 2 hours; Fe powder and Cr powder were ball milled together for 1.5 hours.

[0023] (2) Powder feeding and mixing

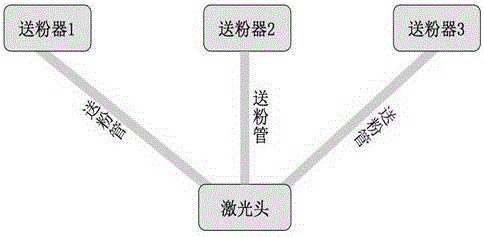

[0024] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Put Ti powder and mixed rare earth powder into the first hopper, graphite powder into the second hopper, and Fe and Cr mixed powder into the third hopper ; Three powder feeders feed powder at the same time, and adjust the content of TiC in the forming part through the screw speed.

[0025] (3) L...

Embodiment 2

[0029] A TiC-FeCr-Gr composite thermoforming die laser forming method, comprising the following processes:

[0030] (1) Raw material formula and pretreatment

[0031] The raw material formula is: graphite 1.26wt.%, Ti9.81wt.%, Cr19.23wt.%, mixed rare earth 0.13wt.%, Fe balance; the raw material is in powder form, the particle size of metal powder and graphite powder is 60 microns; Metal Ti powder and mixed rare earth powder were ball milled together for 3 hours; Fe powder and Cr powder were ball milled together for 1 hour.

[0032] (2) Powder feeding and mixing

[0033] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Put Ti powder and mixed rare earth powder into the first hopper, graphite powder into the second hopper, and Fe and Cr mixed powder into the third hopper ; Three screw powder feeders feed powder at the same time, and adjust the content of TiC in the forming part through the screw speed.

[0034] (3) Laser forming

...

Embodiment 3

[0038] A kind of laser forming method of TiC-FeCr-Gr composite material hot-rolled conveying roll, comprises following process:

[0039] (1) Raw material formula and pretreatment

[0040] The raw material formula is: graphite 3.61wt.%, Ti powder 4.32wt.%, Cr powder 13.47wt.%, mixed rare earth 0.15wt.%, Fe powder 78.45wt.%. Raw materials are in powder form, metal powder and graphite powder particles The size is 200 microns; the metal Ti powder and the mixed rare earth powder are ball milled together for 3 hours; the Fe powder and Cr powder are ball milled together for 1 hour.

[0041] (2) Powder feeding and mixing

[0042] The powder feeding process is completed by a multi-hopper screw powder feeding mixing system. Put Ti powder and mixed rare earth powder into the first hopper, graphite powder into the second hopper, and Fe and Cr mixed powder into the third hopper ; Three screw powder feeders feed powder at the same time, and adjust the equivalent of TiC powder in the mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com