Preparation method for trace ammonia steam

A technology of ammonia vapor and trace ammonia, applied in the direction of separation methods, chemical instruments and methods, evaporation, etc., can solve the problems of safety, hidden dangers, and inability to obtain constant concentration of ammonia vapor, so as to prevent heat dissipation due to direct contact and control accuracy The effect of high and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All equipments in the ammonia steam preparation system involved in the present invention except the ammonia steam generator are general equipments. Among them, ammonia storage tanks, screw pumps, steam heaters, etc. are standard equipment, and there are many manufacturers of related equipment in China.

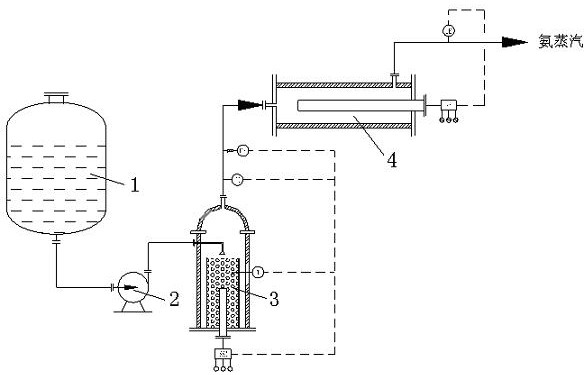

[0026] Such as figure 1 Shown, a kind of trace ammonia vapor preparation method comprises the following steps:

[0027] (1) Prepare an ammonia solution according to the required ammonia concentration, and put it into the ammonia storage tank 1.

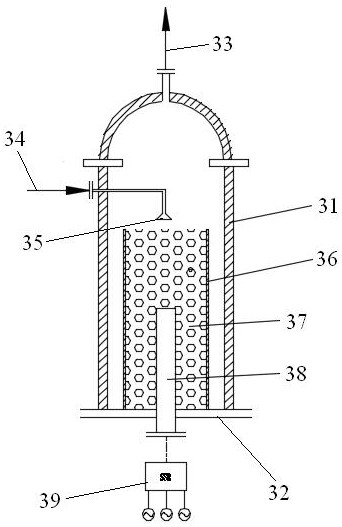

[0028] (2) Turn on the heating power supply of the ammonia steam generator 3 and the ammonia steam heater 4, make the resistance wire in the ammonia steam generator 3 or the radiation heating tube heat the heating ceramic ball 37 in the ammonia steam generator 3, make the heating ceramic ball 37 The temperature rises to 200°C higher than the saturation temperature of water under the corresponding pressure, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com