Deuterium-depleted water preparation device, preparation method and application

A preparation device, a technology of deuterium-depleted water, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as consumption, high energy consumption, large reflux ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

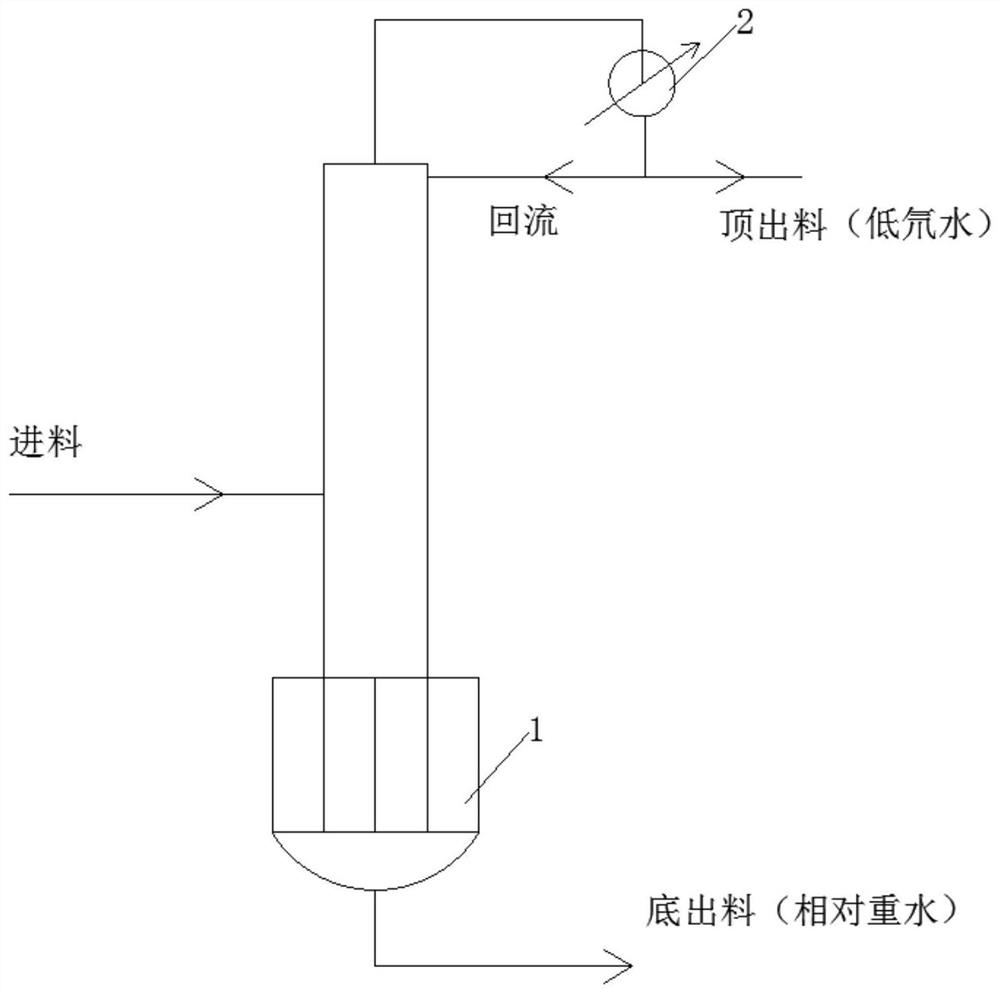

[0040] A method for preparing deuterium-depleted water, comprising the following steps:

[0041] The preheated or non-preheated feed enters the gas-liquid separation device for rectification operation, and the gas phase material flowing out from one end (top) of the gas-liquid separation device enters the first heating device, then heats and pressurizes, and then enters the second heating In the built-in heat exchange parts of the device;

[0042] The material flowing out from the bottom of the gas-liquid separation device is extracted from the bottom of the gas-liquid separation device in the form of bottom discharge. It can be selectively heated and then returned to the gas-liquid separation device, or it can be directly recovered without heating. The material flowing out from the bottom of the liquid separation device enters the second heating device in another way and does not contact the material in the heat exchange element. The material in the heat exchange element is u...

Embodiment 1

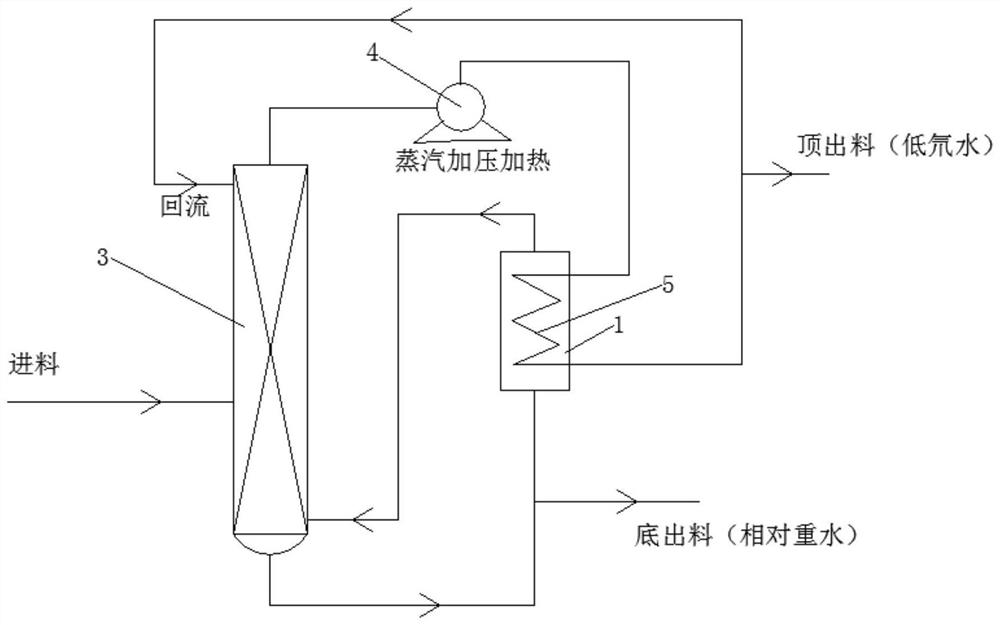

[0045] Such as Figure 2-4 As shown, a deuterium-depleted water preparation device includes a gas-liquid separation device, a first heating device, a second heating device and a third heating device, the gas-liquid separation device is a rectification tower 3, and the first heating device is a vapor compression The pump 4, the second heating device is a reboiler 1, the built-in heat exchange element of the reboiler 1 is a W-shaped heat exchange tube 5, the third heating device is a heat exchanger 6, and the curved heat exchanger built in the third heating device The heat pipe 8 is W-shaped, the top of the rectification tower 3 is connected to the vapor compression pump 4 and then connected to the top of the heat exchange tube 5 built in the reboiler 1, and the bottom of the heat exchange pipe 5 is connected to the top of the rectification tower 3 Connected, used to return the material in the heat exchange tube 5 to the rectification tower 3 through the top of the rectification...

Embodiment 2

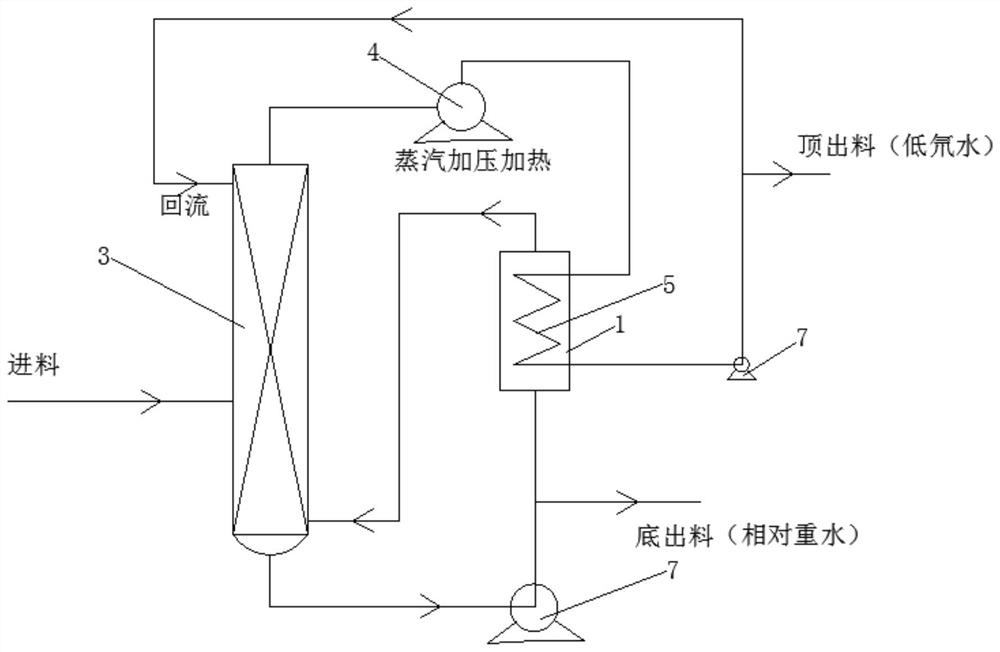

[0056] Such as Figure 2-3 and Figure 5 As shown, a deuterium-depleted water preparation device includes a gas-liquid separation device, a first heating device, a second heating device and a third heating device. The difference between this embodiment 2 and embodiment 1 is that this embodiment 2 is The upstream of the liquid separation device is provided with two third heating devices arranged in parallel and connected sequentially from end to end, and in this embodiment 2, the feed enters another heat exchanger after being heat-exchanged by the heat exchanger 6 farthest from the rectification tower 3 6, and then enter the rectification tower 3, the material flowing out from the bottom of the gas-liquid separation device is extracted from the bottom kettle or the bottom of the rectification tower 3 in the form of bottom discharge, and then sent to the third heating station closest to the gas-liquid separation device The device is preheated before discharge.

[0057] The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com