Method for additive manufacturing repair of ultra-thin structures

An additive manufacturing and ultra-thin technology, which is applied in the field of additive manufacturing and repair of ultra-thin structures, can solve problems such as difficulty in meeting design requirements for dimensional accuracy, deformation of ultra-thin structures, and long time required to expand the use range of equipment and quickly Effects of repairing and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

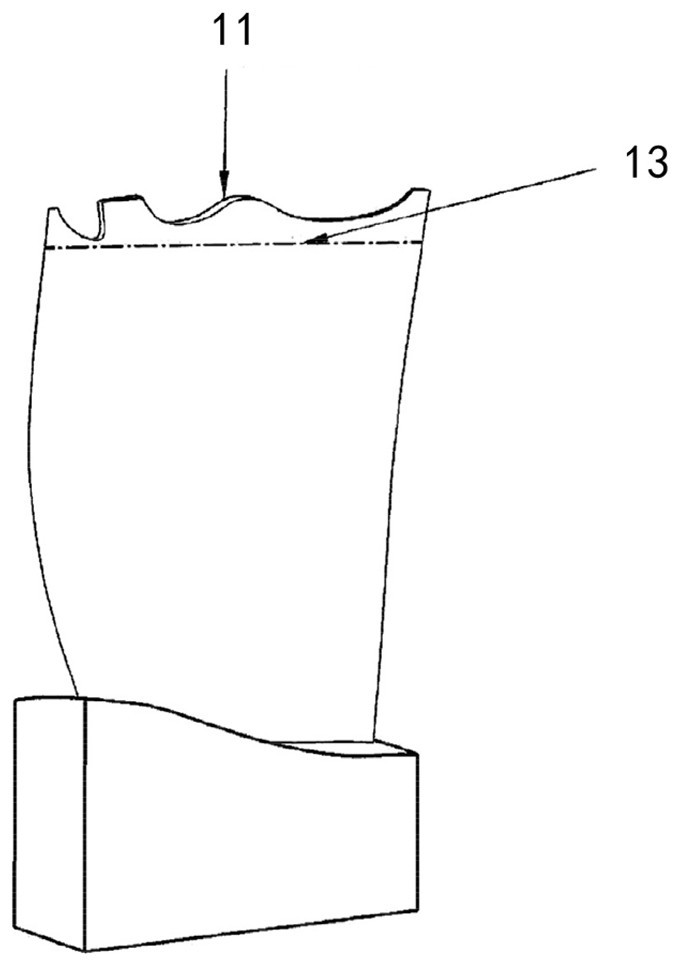

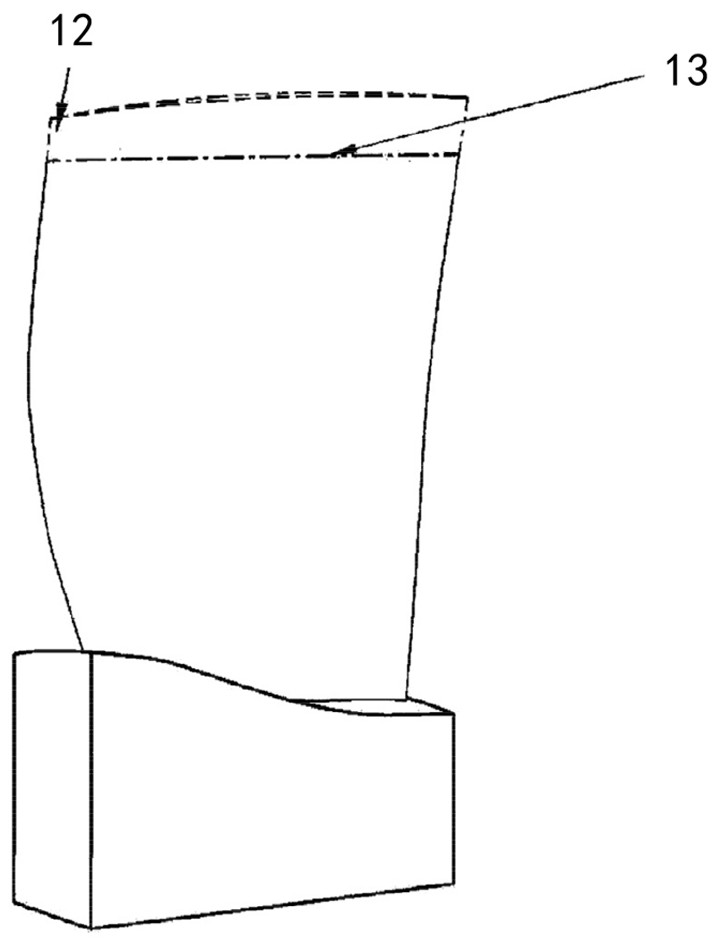

[0064] The first embodiment: compressor blade tip repair

[0065] (1) Blade tip damage machining: The entire blade tip (including the damaged area) is machined and removed.

[0066] (2) Three-dimensional modeling of the area to be repaired: 3D modeling of the area to be repaired is carried out by modeling software such as UG and CAD.

[0067] (3) Model processing: Add margin (0.5mm) to the 3D model of the area to be repaired, layered slicing, and path planning.

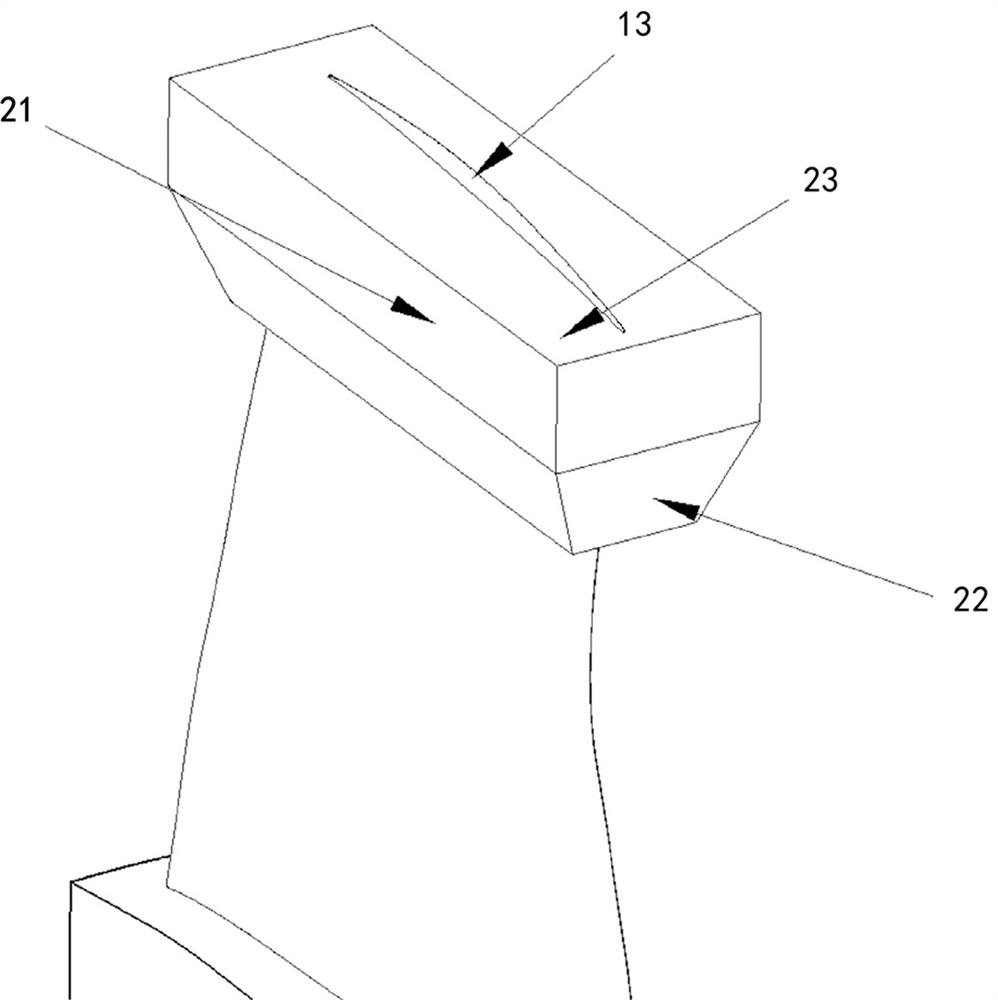

[0068] (4) Adaptive clamping at the bottom of the area to be repaired: Adaptively build powder loading devices 21 on both sides of the bottom of the area to be repaired with soft metal materials such as aluminum foil, and fix them to the compressor blades with high-temperature resistant adhesive tape 22, such as figure 2 shown.

[0069] (5) Filling the powder loading device with powder: Fill the powder loading device 21 with Ti17 metal powder 23, and scrape off the powder so that the powder is flush with the bottom...

no. 2 example

[0074] The second embodiment: repairing the front and rear edges of compressor blades

[0075] (1) Machining of front and rear edge damage: The damage area of front and rear edges is machined and removed according to the principle of minimum damage to form a regular trapezoidal groove.

[0076] (2) Three-dimensional modeling of the area to be repaired: 3D modeling of the area to be repaired is carried out by modeling software such as UG and CAD.

[0077] (3) Model processing: The 3D model of the area to be repaired is subjected to margin addition processing (0.5-1mm), layered slice processing, and path planning processing.

[0078] (4) Adaptive clamping at the bottom of the area to be repaired: Adaptively build powder loading devices 21 on both sides of the bottom of the area to be repaired with soft metal materials such as aluminum foil, and fix them to the compressor blades with high-temperature resistant adhesive tape 22, such as image 3 shown.

[0079] (5) Fill the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com