Humanoid pneumatic soft robot finger

A pneumatic and pneumatic actuator technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inability to balance output force and response time, insufficient output force in response time, poor friendliness and safety, etc., to achieve performance Excellent, impressive output, and fast recovery results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

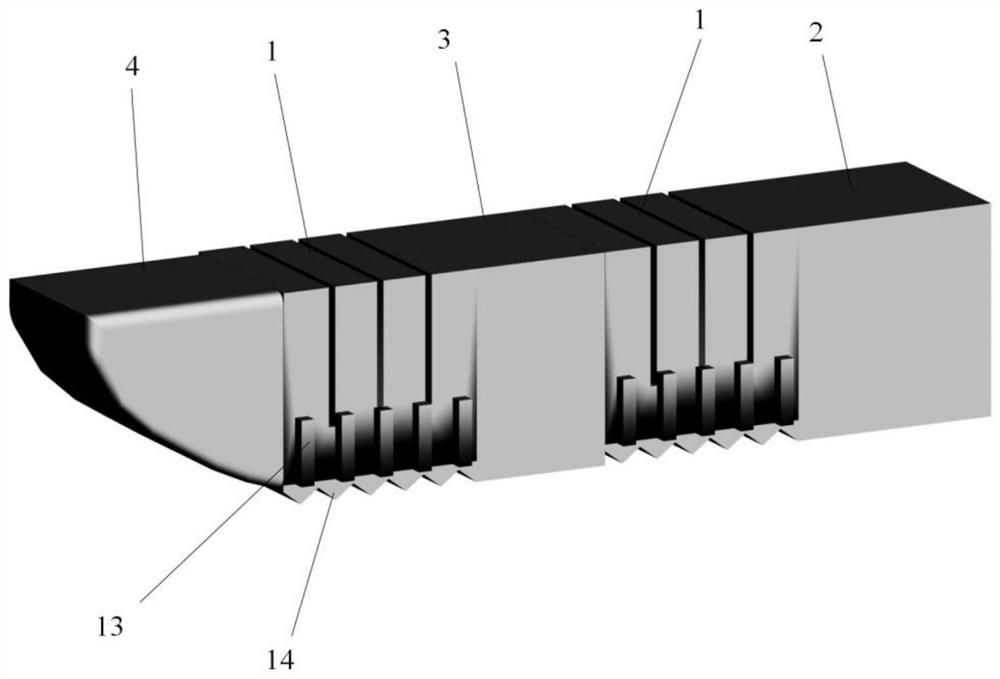

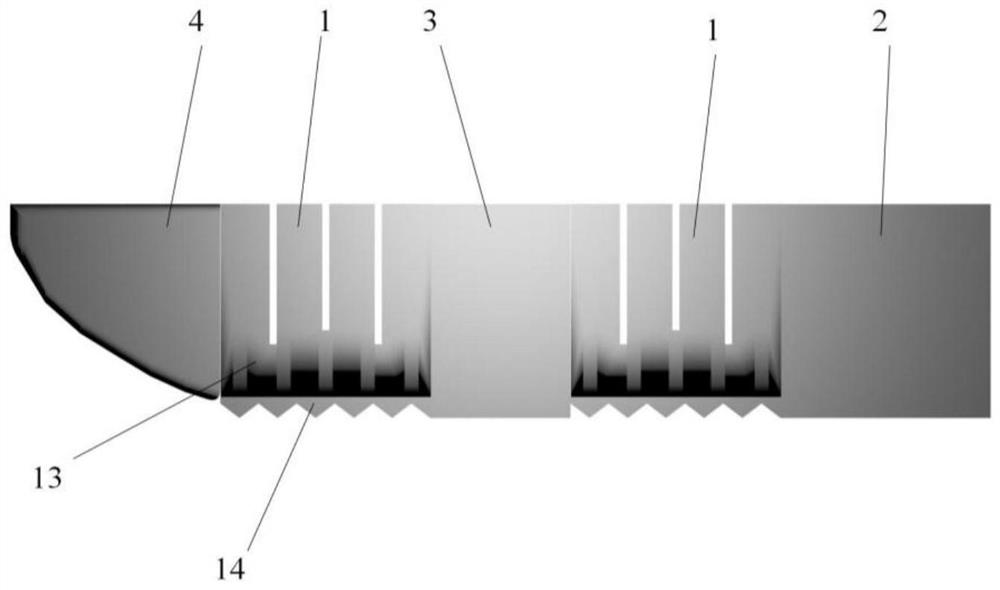

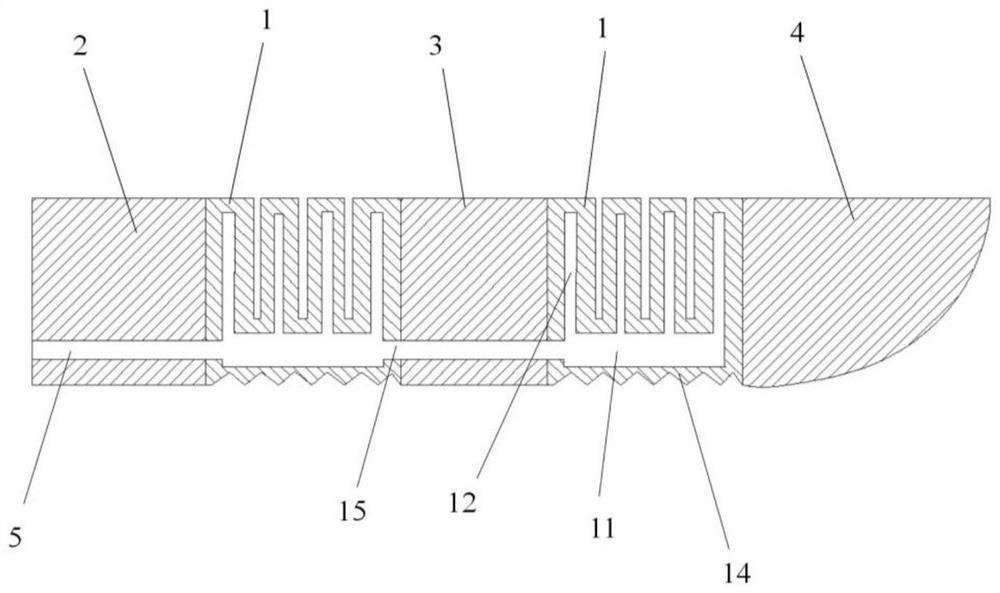

[0045] Such as Figure 1~4 As shown, a humanoid pneumatic soft robot finger in this embodiment has the following structure:

[0046] It includes the front flexible unit 4, the middle flexible phalanx unit 3 and the rear flexible phalanx unit 2; there is a connection between the front flexible unit 4 and the middle flexible phalanx unit 3, and between the middle flexible phalanx unit 3 and the rear flexible phalanx unit 2. Pneumatic actuator unit 1.

[0047] The pneumatic actuator unit has a comb-like structure as a whole, including a base and a plurality of combs arranged side by side along the length of the finger; a main cavity 11 is provided inside the base, and each comb is provided with a The sub-cavities 12 connected to the main cavity;

[0048] Both the middle flexible phalanx unit 3 and the rear flexible phalanx unit 2 are provided with an air passage 5 running through the length direction of the finger, and the air passage 5 passes through the opening 15 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com