Stabilized soil stirring plant

A mixing station and soil stabilization technology, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve problems such as low mixing efficiency, long mixing time, and easy falling of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

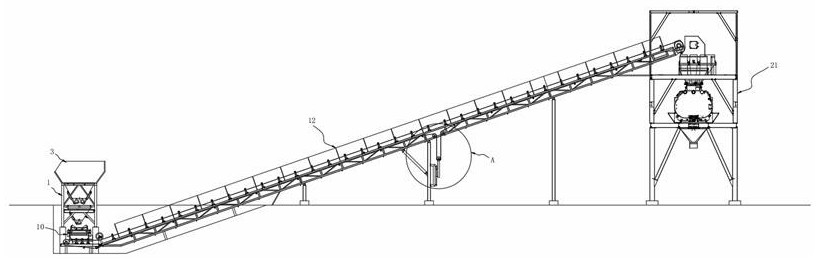

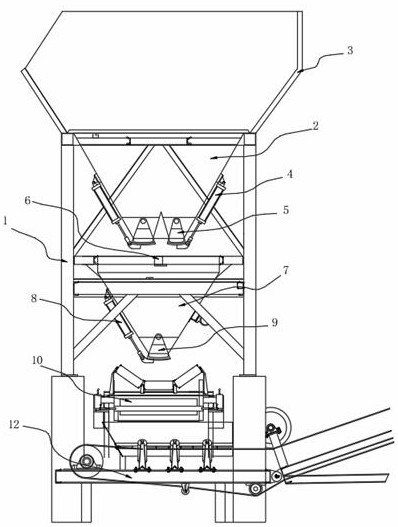

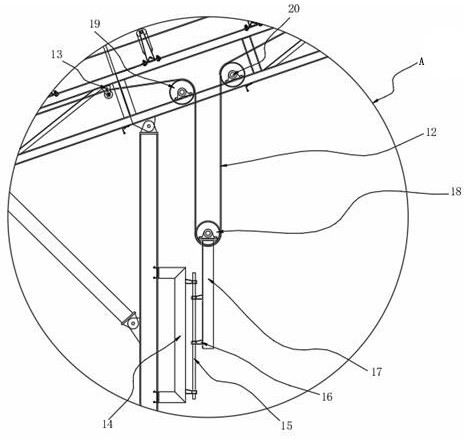

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 shown;

[0031] figure 1 It is a schematic diagram of the overall structure of the present invention;

[0032] figure 2 It is a schematic diagram of the installation structure of the first bracket and the aggregate storage bucket in the present invention;

[0033] image 3 for the present invention figure 1 Schematic diagram of the structure at A;

[0034] Figure 4 It is a schematic diagram of the installation structure of the first support and the conveyor belt conveyor in the present invention;

[0035] Figure 5 It is a schematic diagram of the installation structure of the control room and the second support in the present invention;

[0036] Figure 6 It is a schematic diagram of the cross-sectional installation structure of the housing and the motor protection case in the present invention;

[0037] Figure 7 for the present invention Figure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap