Wine box top cover forming machine

A molding machine and top cover technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of no multiple-pressed bubble structure, inability to fit lining and leather shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The wine box top cover molding machine of the present invention is suitable for molding various box body top covers.

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 , describe in detail the preferred embodiment and other embodiments of the wine box top cover forming machine of the present invention.

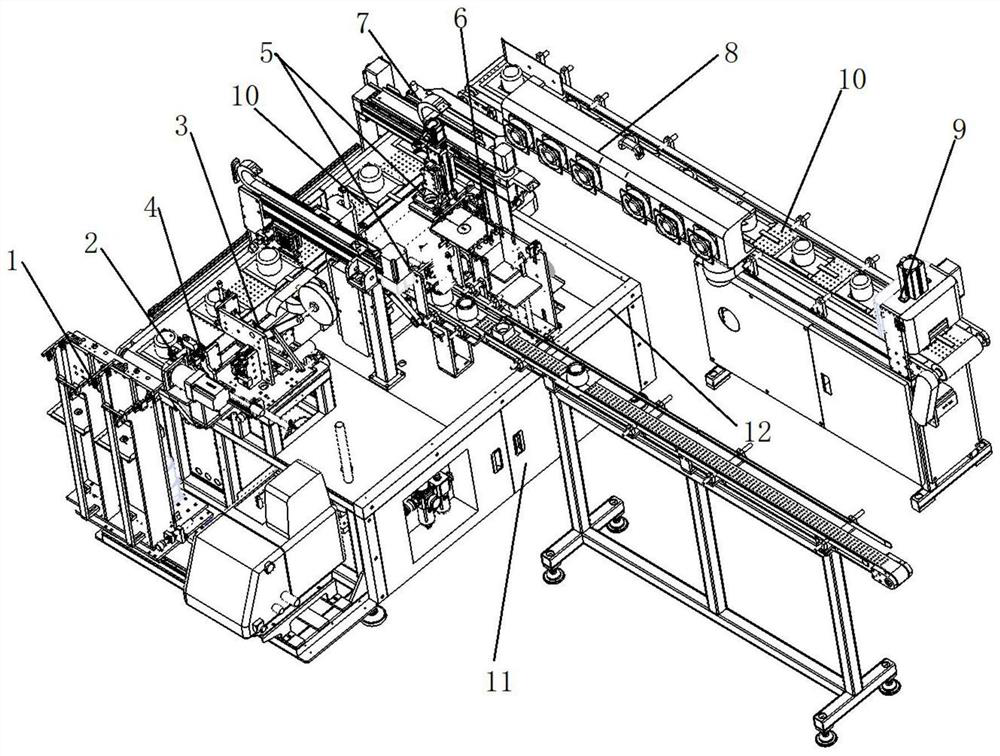

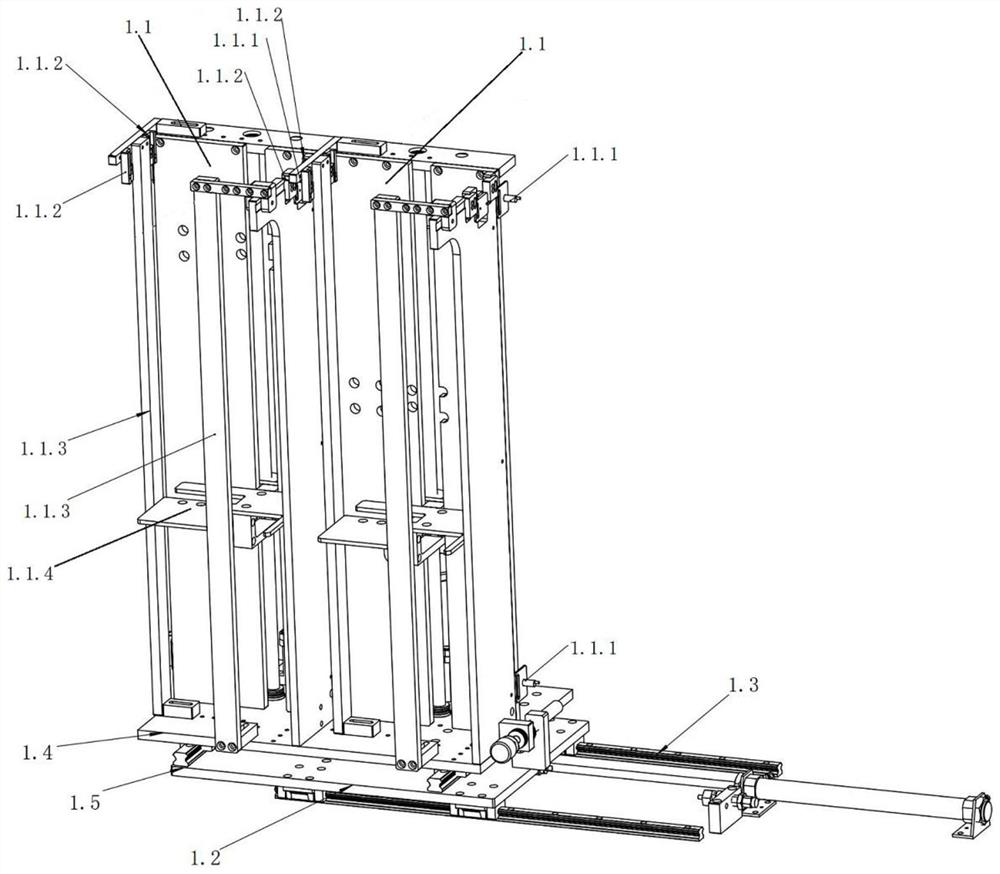

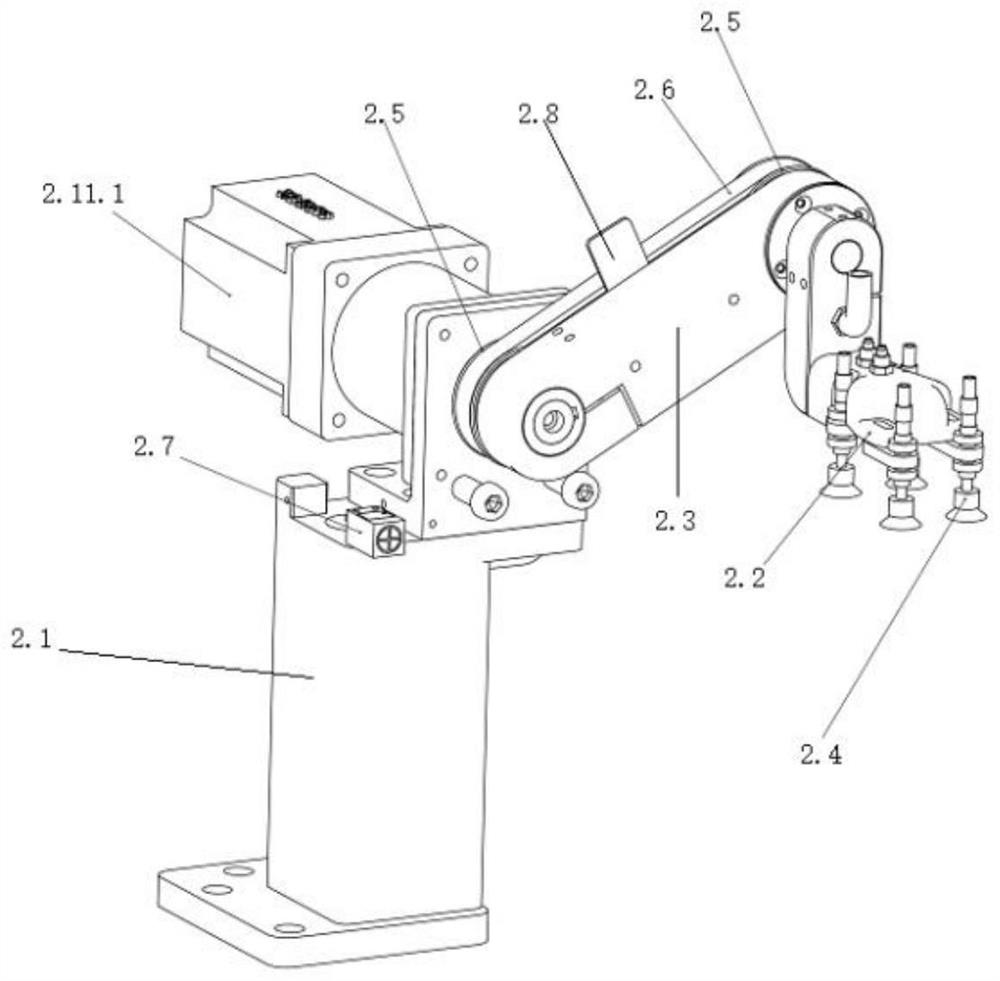

[0028] refer to figure 1 , in this embodiment, the wine box top cover forming machine of the present invention includes a feeding device 1, a material retrieving robot arm 2, a glue dispensing device 4, a wine box top cover belt forming and setting transfer integrated device 3, and an inner lining Material positioning device 6, liner or wine bottle positioning piece synchronously acquire glue lamination positioning manipulator 5, first defoaming device 7, drying device 8, second defoaming device 9, conveying device 10, control device 11 and Machine base 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com