Alkali-activated concrete for sewage pipeline

A sewage pipeline and alkali excitation technology, applied in the field of building materials, can solve the problems of aggravating the corrosion of pipeline concrete, affecting the service life of the sewer pipeline, and destroying the concrete structure, achieving compact structure, improving impermeability and durability, and reducing corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

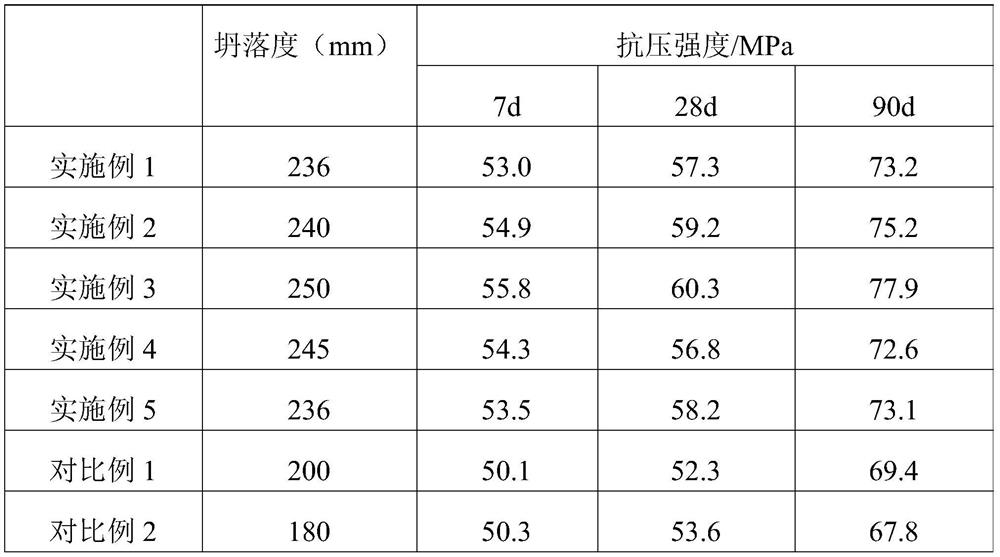

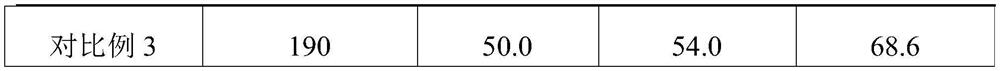

Examples

Embodiment 1

[0027] An alkali-activated concrete for sewage pipelines: comprising the following raw materials in parts by weight: 45 parts of slag, 10 parts of silica fume, 6 parts of metakaolin, 5 parts of fly ash, 40 parts of water, 35 parts of alkali activator, and 0.25 parts of admixture , 0.5 parts of fiber, 100 parts of fine aggregate, and 75 parts of coarse aggregate.

Embodiment 2

[0029] An alkali-activated concrete for sewage pipelines: comprising the following raw materials in parts by weight: 75 parts of slag, 15 parts of silica fume, 12 parts of metakaolin, 10 parts of fly ash, 50 parts of water, 45 parts of alkali activator, and 0.5 parts of admixture , 1 part of fiber, 150 parts of fine aggregate, and 125 parts of coarse aggregate.

Embodiment 3

[0031] An alkali-activated concrete for sewage pipelines, comprising the following raw materials in parts by weight: 60 parts of slag, 13 parts of silica fume, 10 parts of metakaolin, 8 parts of fly ash, 45 parts of water, 40 parts of alkali activator, and 0.4 parts of admixture parts, 0.8 parts of fiber, 125 parts of fine aggregate, and 100 parts of coarse aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com