Antibacterial film product and preparation process

A technology of thin film products and preparation process, which is applied in the field of plastic products, can solve the problems of affecting the long-lasting antibacterial effect, the antibacterial durability needs to be improved, and the ultra-fine antibacterial agent powder, so as to increase stability and weather resistance and prevent growth. With agglomeration, long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

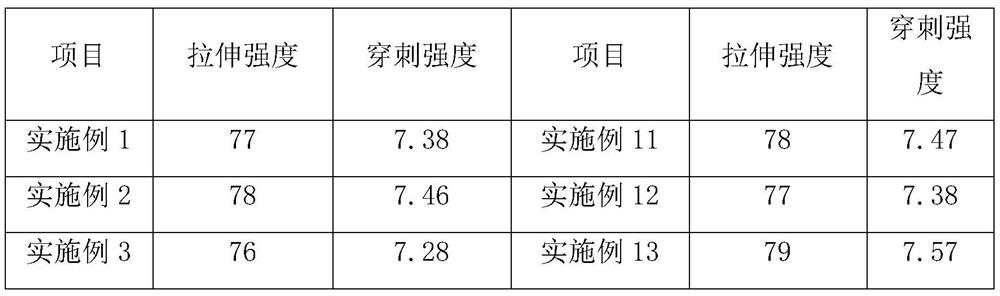

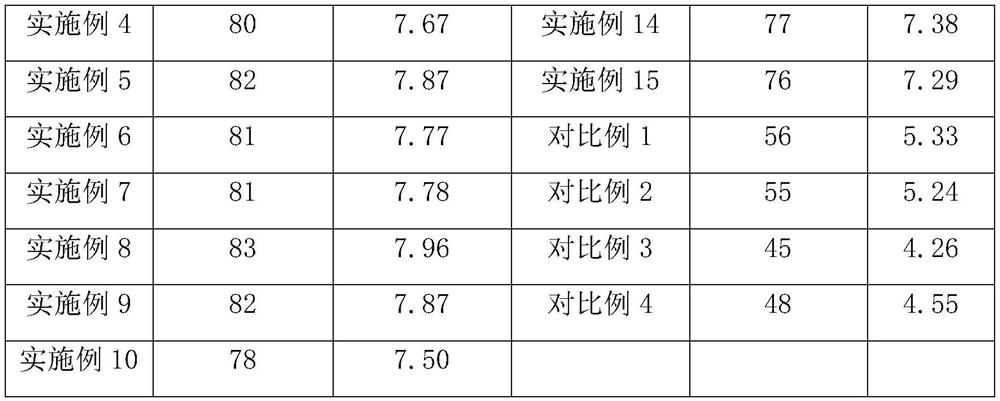

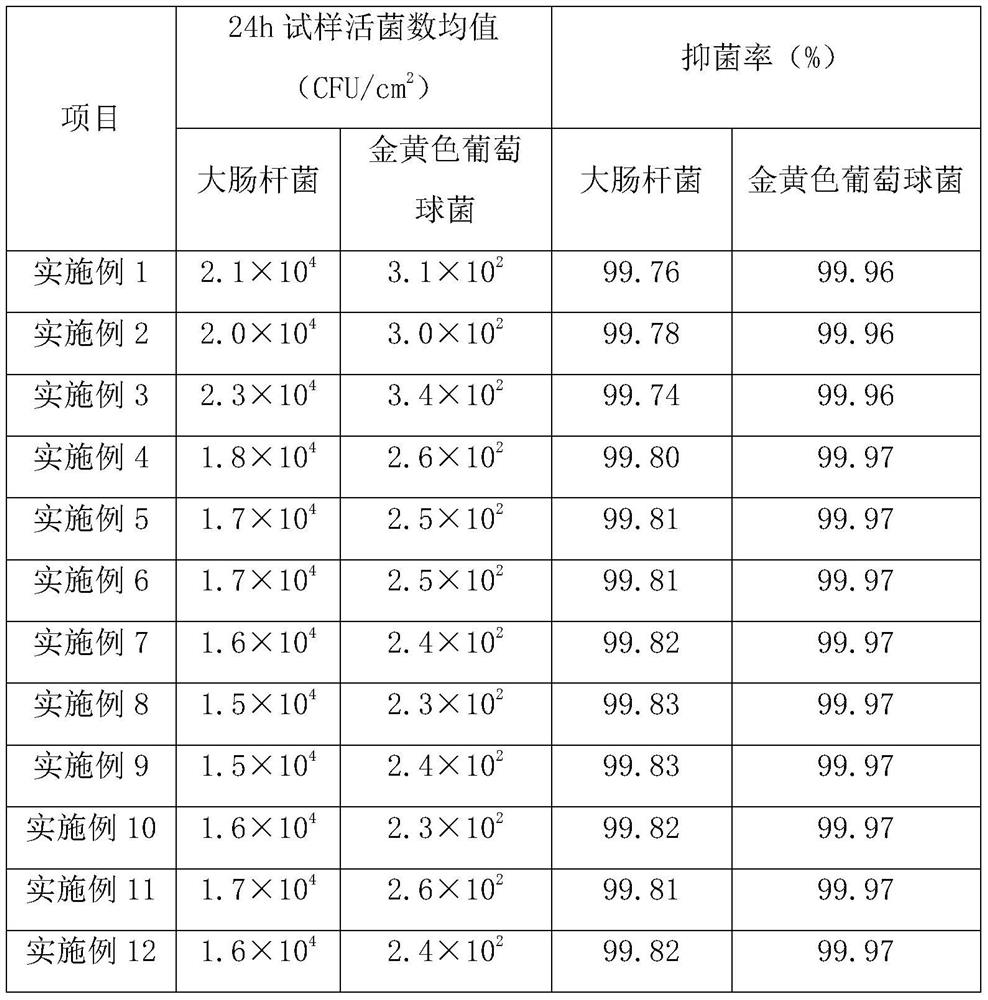

Examples

preparation example 1

[0054] The preparation method of silicate / silver composite powder comprises the following steps:

[0055] 1) Set the molar concentration to 0.5×10 -3 mol / L silver nitrate solution and polyvinylpyrrolidone aqueous solution with a mass concentration of 1.2% are mixed in a volume ratio of 4:1 to obtain a mixed solution;

[0056] 2) Mix 80 g of the mixed solution in step 1) with 3 g of kaolin to obtain a reaction solution, and stir for 4 hours;

[0057] 3) After adding 0.2 g of glucose to the reaction solution to continue the reaction for 2 hours, filter and dry at 60° C. for 24 hours to obtain a silicate / silver composite powder;

[0058] Among them, the average particle size of kaolin is 20-30 μm.

preparation example 2

[0060] The preparation method of silicate / silver composite powder comprises the following steps:

[0061] 1) Set the molar concentration to 1.5×10 -3 mol / L silver nitrate solution and polyvinylpyrrolidone aqueous solution with a mass concentration of 1% are mixed in a volume ratio of 4.5:1 to obtain a mixed solution;

[0062] 2) Mix 90 g of the mixed solution in step 1) with 2.5 g of kaolin to obtain a reaction solution, and stir for 4.5 hours;

[0063] 3) After adding 0.3 g of glucose to the reaction solution to continue the reaction for 1.5 h, filter and dry at 60° C. for 24 h to obtain a silicate / silver composite powder;

[0064] Among them, the average particle size of kaolin is 20-30 μm.

preparation example 3

[0066] The preparation method of silicate / silver composite powder comprises the following steps:

[0067] 1) Set the molar concentration to 2×10 -3 mol / L silver nitrate solution and polyvinylpyrrolidone aqueous solution with a mass concentration of 0.8% are mixed in a volume ratio of 5:1 to obtain a mixed solution;

[0068] 2) Mix 100 g of the mixed solution in step 1) with 2 g of kaolin to obtain a reaction solution, and stir for 5 hours;

[0069] 3) After adding 0.5 g of glucose to the reaction solution to continue the reaction for 1 hour, filter and dry at 60° C. for 24 hours to obtain a silicate / silver composite powder;

[0070] Among them, the average particle size of kaolin is 20-30 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com