Glass fiber reinforced polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, which are applied in the field of polymer materials, can solve the problems of easy occurrence of floating fibers and poor compatibility, and achieve the effects of low dimensional stability, low floating fibers, high production efficiency, and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

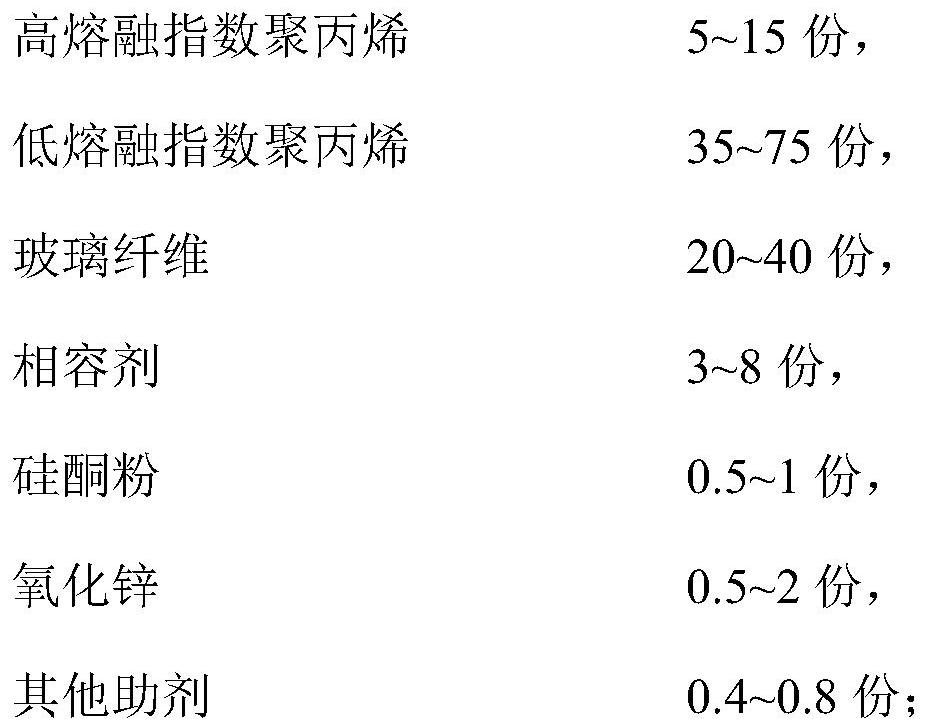

[0033] According to parts by weight, 5 parts of high melt index polypropylene with a melt index of 100g / 10min, 72 parts of low melt index polypropylene with a melt index of 10g / 10min, 3 parts of PP-g-MAH with a graft rate of 1.0%, Add 0.5 part of silicone powder, 0.5 part of zinc oxide (Zibo Haishun Zinc Industry Co., Ltd.), 0.2 part of antioxidant 1330 and 0.2 part of antioxidant 168 into a high-speed mixer at 70°C and mix for 4 minutes at 1000 rpm, then mix The mixture is put into the feeding barrel of the twin-screw extruder, and 20 parts of chopped non-alkali glass fiber with a glass fiber length of 3.0 mm and a single filament diameter of 13 μm are fed into the extruder from the side feeding port, and the main engine speed is 300 rpm , the main feeding speed is 11rpm, and the side feeding speed is 10rpm, and then extruded and granulated by a twin-screw extruder to obtain the low-floating fiber glass fiber reinforced polypropylene composition described in Example 1, wherein...

Embodiment 2

[0035] According to parts by weight, 10 parts of high melt index polypropylene with a melt index of 150g / 10min, 56 parts of low melt index polypropylene with a melt index of 3g / 10min, 4 parts of PP-g-MAH with a graft rate of 1.2%, 1 part of silicone powder, 1 part of zinc oxide (Weifang Hengfeng Chemical Co., Ltd.), 0.2 part of lubricant EBS, 0.2 part of antioxidant 1330 and 0.2 part of antioxidant 168, add to a high-speed mixer and mix at 70°C and 800rpm 6 minutes, put this mixture into the feeding barrel of the twin-screw extruder again, glass fiber length 4.5mm, 30 parts of short-cut alkali-free glass fibers with a monofilament diameter of 14 μm are added to the extruder from the side feed port, wherein , the host speed is 350rpm, the main feed speed is 12rpm, and the side feed speed is 11rpm, then extruded and granulated by a twin-screw extruder to obtain the low-floating fiber glass fiber reinforced polypropylene composition described in Example 2, wherein the two The wor...

Embodiment 3

[0037] According to parts by weight, 12 parts of high melt index polypropylene with a melt index of 200g / 10min, 47 parts of low melt index polypropylene with a melt index of 5g / 10min, 6 parts of PP-g-MAH with a graft rate of 1.5%, 1 part of silicone powder, 1.5 parts of zinc oxide (Weifang Hengfeng Chemical Co., Ltd.), 0.3 parts of lubricant EBS, 0.25 parts of antioxidant 1330 and 0.25 parts of antioxidant 168 are added to a high-speed mixer at 80°C and mixed at 600rpm 5 minutes, put this mixture into the feeding barrel of the twin-screw extruder again, glass fiber length 4.0mm, 35 parts of short-cut alkali-free glass fibers with a monofilament diameter of 15 μm are added to the extruder from the side feed port, wherein , the host speed is 400rpm, the main feed speed is 13rpm, and the side feed speed is 13rpm, then extruded and granulated by a twin-screw extruder to obtain the low-floating fiber glass fiber reinforced polypropylene composition described in Example 3, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com