Neutron shielding material for rotational molding and rotationally molded products with neutron shielding effect

A shielding effect, neutron technology, applied in the field of rotational molding products, can solve the problems of low shielding efficiency of neutron shielding materials, different equipment shapes, large thickness, etc., to improve neutron shielding efficiency, wide use temperature range, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

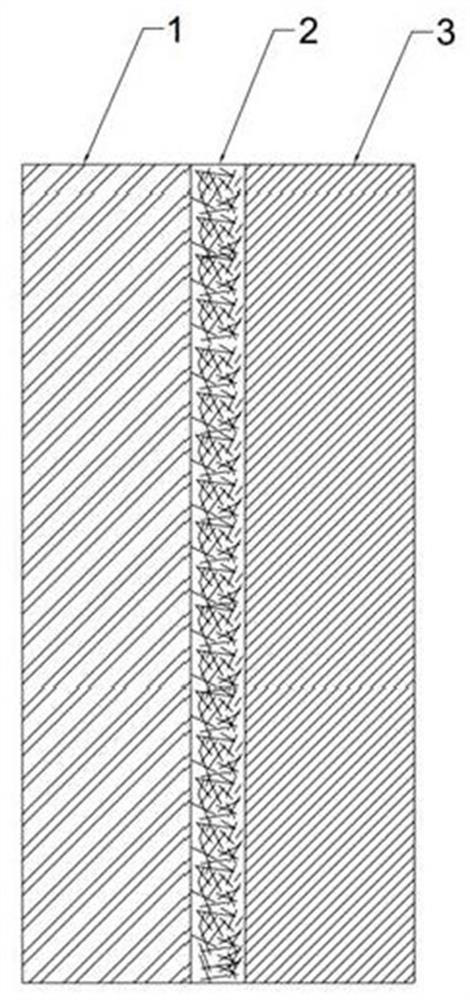

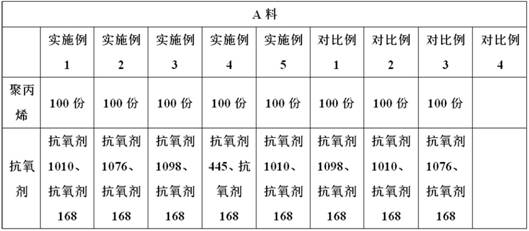

[0040] Formulation composition of Table 1 A material and B material

[0041]

[0042]

[0043] Utilize the neutron shielding material for rotomolding in the above embodiment to prepare rotomolded products, the steps are as follows:

[0044] (1) Prepare the raw materials by weight first, stir the polypropylene, the first antioxidant, the first lubricant and the heavy metal compound in a high-speed mixer at a speed of 50rpm for 8 minutes to obtain the first mixture; melt the first mixture After blending, granulate and grind; mix the ground powder and boron-containing fiber in a high-speed mixer at a speed of 30 rpm for 3 minutes to obtain material A;

[0045] Prepare each raw material by weight first, polypropylene, the second antioxidant, the second lubricant and the compound containing boron are stirred at a speed of 50 rpm in a high-speed mixer to obtain the second mixture for 8 minutes; the second mixture is melted After blending, granulate and grind to obtain materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com