Tobacco flavor and preparation method thereof

A technology for tobacco flavors and aroma-causing substances is applied in the field of heating cigarette flavors, which can solve the problems of rapid loss of aroma, uneven aroma, and non-persistent aroma, and achieve the effects of improving consumer experience, lasting and stable aroma, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the preparation method provided by the present invention, the contact of the solid acid and the glycoside can be carried out in any way, for example, mixing in a solid phase, a liquid phase or a combination thereof. In a preferred embodiment of the present invention, the contacting may be performed by grinding and mixing the solid acid and the solid glycoside; and / or may be performed by soaking the solid acid in the glycoside solution.

[0031] When the contacting is performed by grinding and mixing the solid acid and the solid glycoside as described above, the mixing ratio of the solid acid and the solid glycoside may be 1:5-1:1000 (weight ratio). When the contacting is carried out by dipping the solid acid in a glycoside solution as described above, the glycoside solution may be a solution of glycoside in water, ethanol, propylene glycol, glycerol, or combined, and the contacting may further include baking or drying at a low temperature after the solid acid is soak...

Embodiment 1

[0038] In geraniol glucoside, add the solid acid of 5% (weight ratio) (the chemical composition of the solid acid used in the embodiment is expressed as with the mol ratio of oxide compound: aNa 2 O:bAl 2 o 3 : cSiO 2 , where a<0.1%, b / c=1 / 25), and mix well.

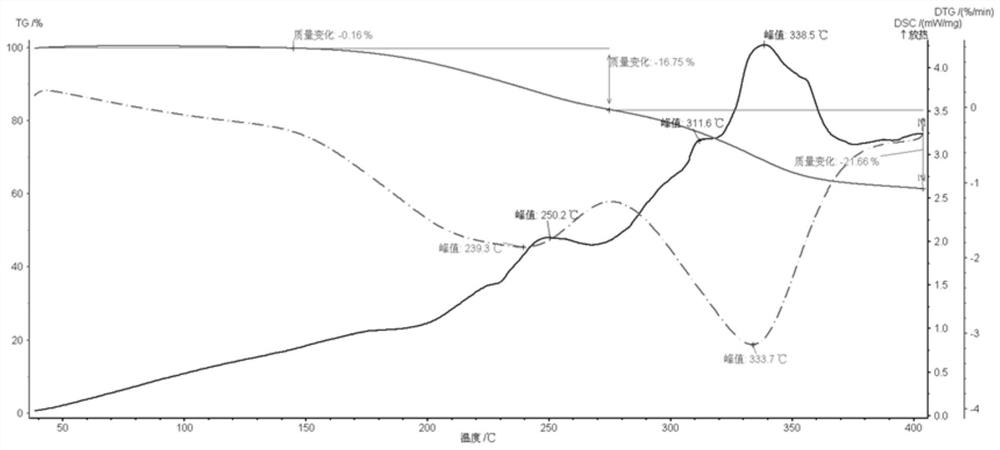

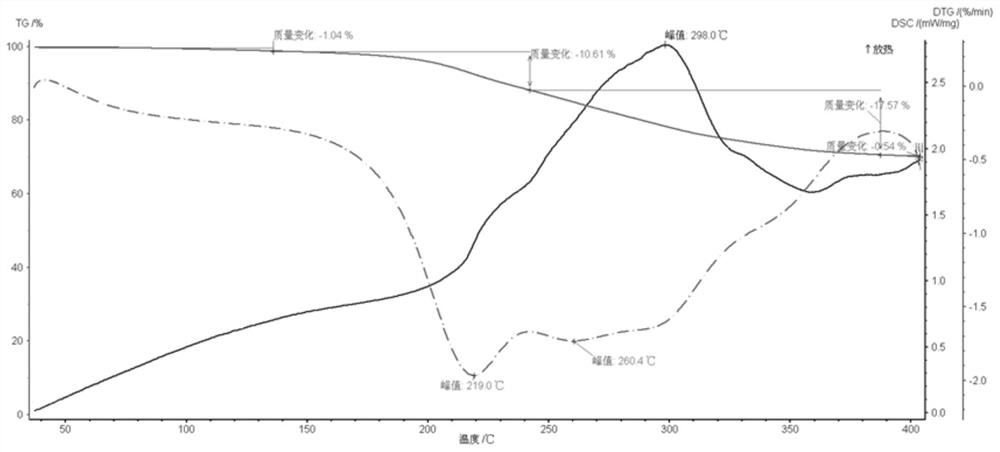

[0039] The resulting mixture and pure geraniol glucoside were put into CDS 5250T pyrolysis apparatus for cracking and analysis respectively. The sample cell used in the cracking test is a stainless steel high-pressure crucible with a gold-plated gasket, with a capacity of 30 μL and a maximum pressure resistance of 15 MPa. The reference crucibles are all high-pressure stainless steel crucibles of the same material. The heating rate (β) of the dynamic DSC test is 10°C / min, the test temperature range is 30-800°C, and the sample mass (m) is 3.5±0.05mg. Comparative analysis figure 1 with figure 2 (the DSC-TG-DTG collection of illustrative plates of pure geraniol glucoside and geraniol glucoside+5% solid acid according ...

Embodiment 2

[0042] Add 10% (by weight) solid acid (same as Example 1) to the menthol glucoside, and mix well.

[0043] The resulting mixture and pure menthol glucoside were put into CDS 5250T pyrolysis apparatus for cracking and analysis respectively. Cracking condition is identical with embodiment 1. The weight loss peaks of pure menthol glucoside DTG curves were at 243°C and 315°C, respectively, while the DTG weight loss peaks decreased to 204°C and 228°C after adding solid acid. This shows that the solid acid greatly reduces the thermal cracking temperature of menthol glucoside.

[0044] The mixture solid of menthol glucoside + 10% (weight ratio) solid acid and tobacco powder are evenly mixed according to the weight ratio of 1:2000 to prepare tobacco flakes, and the tobacco flakes and cooling nozzle rods are connected through tipping paper to form Low-temperature cigarettes; in addition, menthol glucoside solids and tobacco powder were uniformly mixed according to a weight ratio of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com