Twisted roots rotor as well as design method thereof, compressor and expander

A design method and rotor technology, applied in machine/engine, rotary piston machinery, design optimization/simulation, etc., can solve problems such as limited area utilization, single parameters, and increased twisted-blade Roots rotor profile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

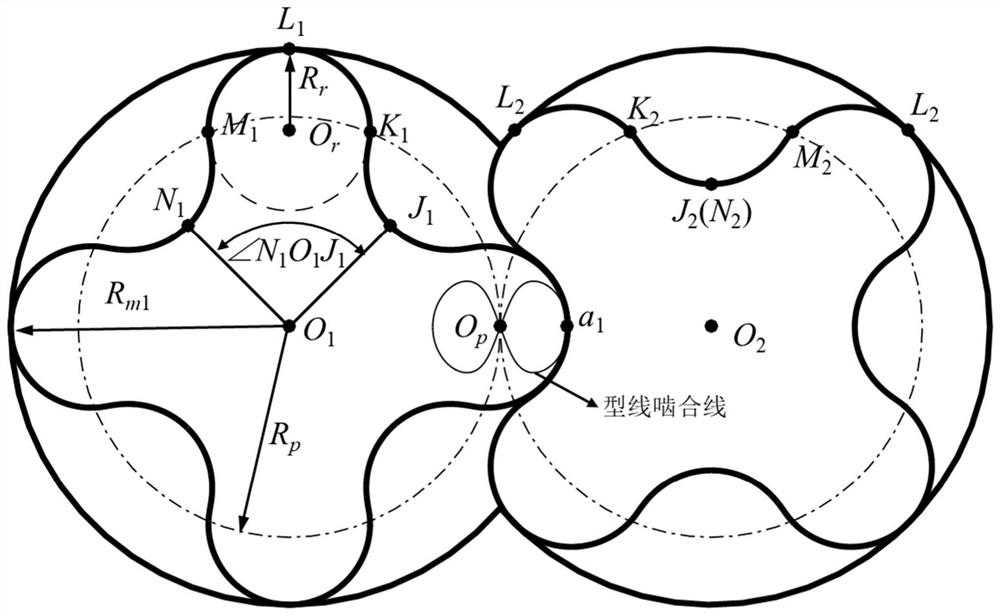

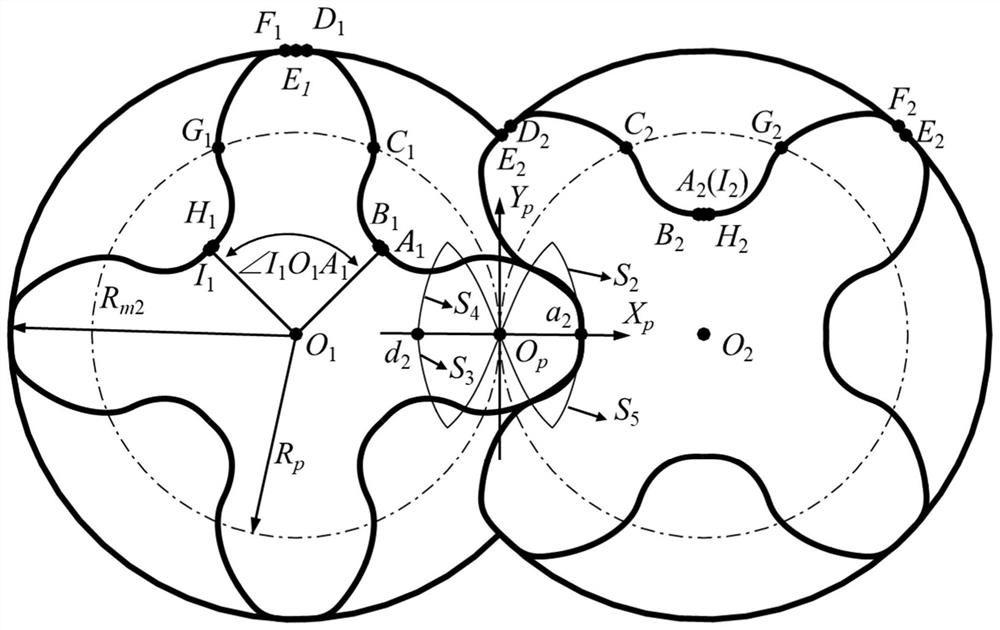

[0067] A design method for a twisted-lobe Roots rotor, comprising the following steps:

[0068] 1) Determine pitch circle radius R p , the target aspect ratio and the number of teeth n. In this example, Take 1.4.

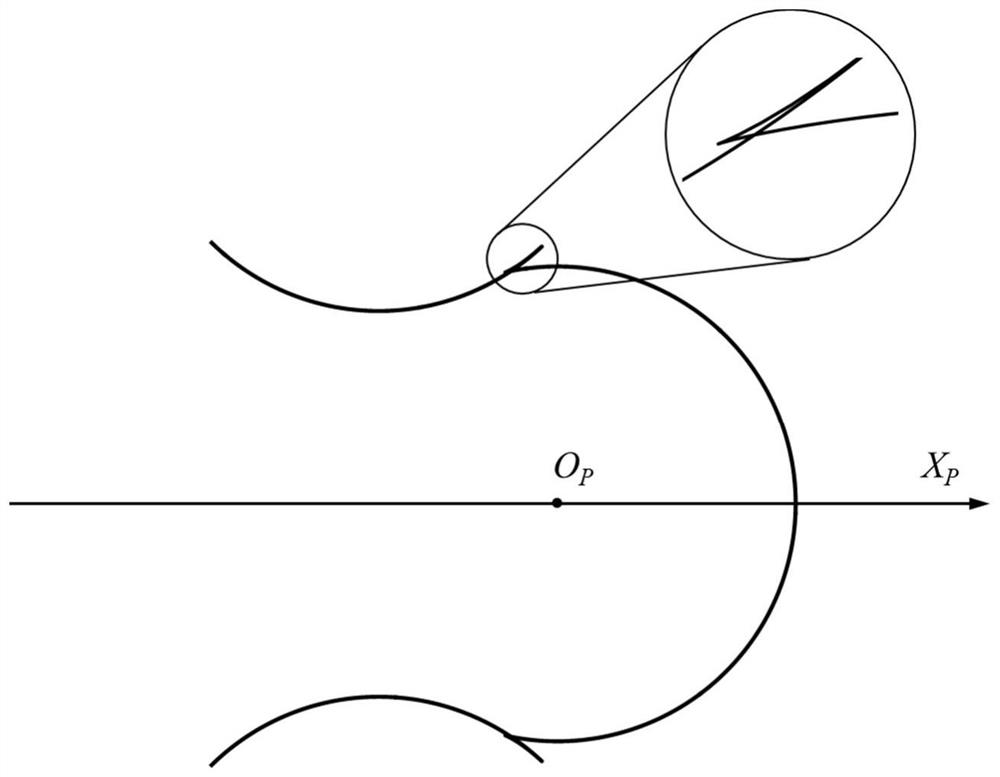

[0069] 2) Generate meshing line bus S 1 , S 1 is the arc segment L of the original arc type line 1 m 1 Corresponding meshing lines, such as Figure 4 shown. S 1 aspect ratio Satisfy is the maximum diameter-to-spacing ratio when the tooth curve just does not produce undercutting phenomenon, when n=4, It can be seen that the original arc profile cannot reach the target diameter-to-spacing ratio requirements. in this example Take 1.32.

[0070] Let the tangent point of the yin and yang rotor pitch circle be O p , in the coordinate system X p o p Y p Medium, L 1 m 1 Segment corresponding to meshing line S 1 parametric equation for:

[0071]

[0072] in, is the arc segment L 1 m 1 The tooth curve equation, is the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com