A high temperature corrosion monitoring system for water wall based on real-time monitoring of CO

A high-temperature corrosion and monitoring system technology, which is applied in the control of fluid heaters, the indication of boiler working conditions, lighting and heating equipment, etc. The process is convenient and fast, avoiding pollution, and ensuring the effect of monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

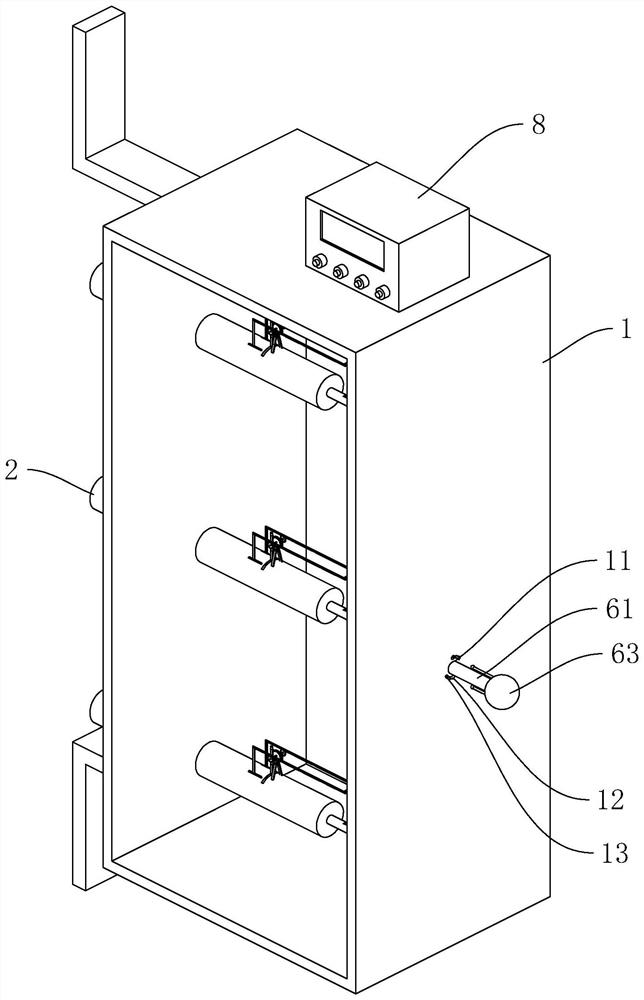

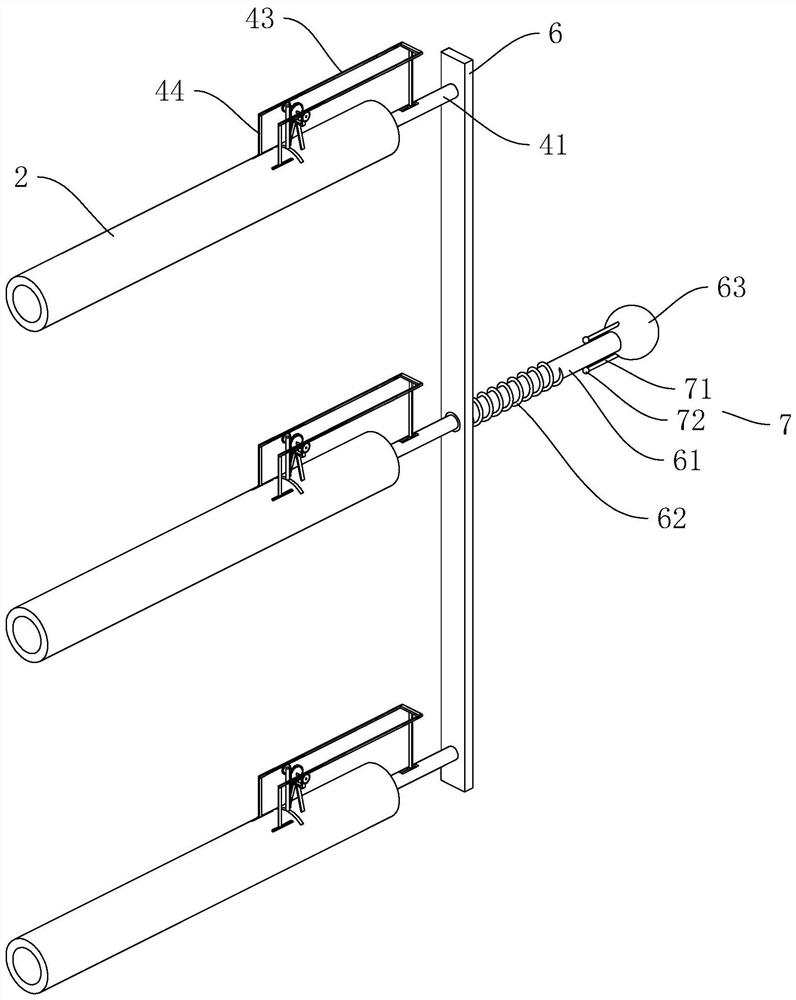

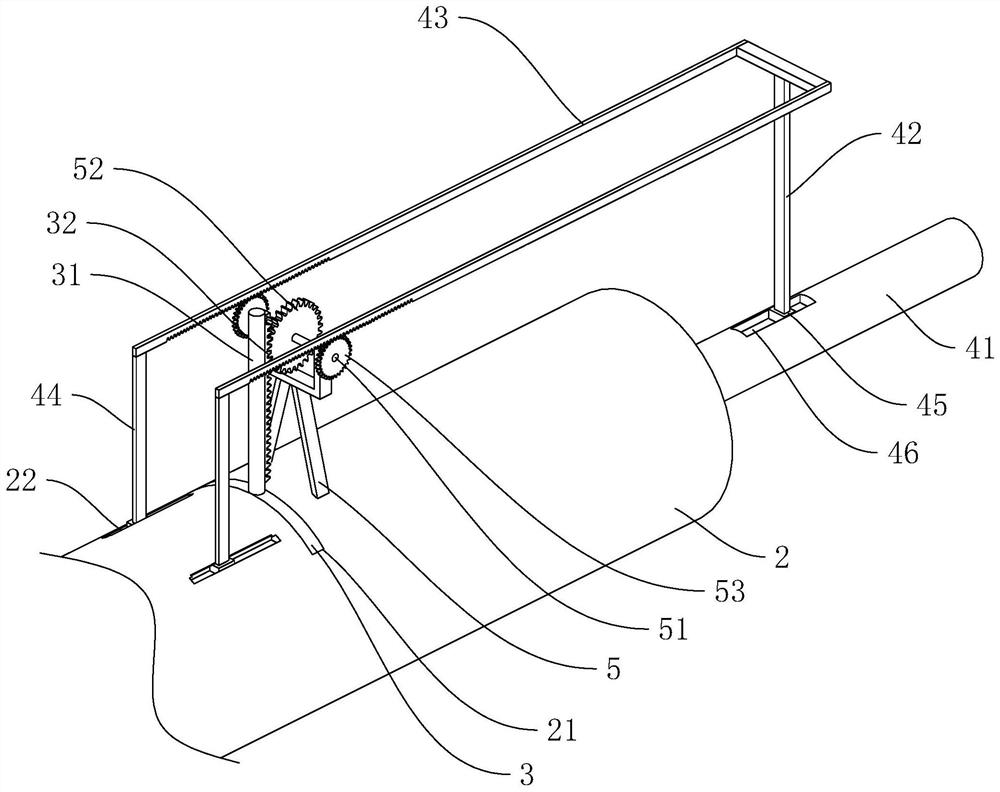

[0035] Attached to the following Figure 1-4 This application will be described in further detail.

[0036] The embodiment of the present application discloses a high-temperature corrosion monitoring system for a water-cooled wall based on CO real-time monitoring. refer to figure 1 , the monitoring system includes an installation frame 1 and a plurality of monitoring tubes 2, the installation frame 1 is a rectangular frame and is vertically fixed on the outer wall of the boiler. A plurality of monitoring tubes 2 are horizontally fixed on the installation frame 1, wherein the plurality of monitoring tubes 2 are evenly distributed along the height direction of the installation frame 1, and one end of which is connected to the interior of the boiler to realize sampling at different heights of the boiler.

[0037] refer to figure 2 , image 3 , a valve plate 3 is arranged vertically in the middle of the monitoring pipe 2 , and the periphery of the valve plate 3 is pressed again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com