Evaporative heat dissipation device and method for high heat flux density electronic device

A technology of high heat flux and electronic devices, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problem of difficulty in fully spreading the liquid film, achieve reduced energy consumption and equipment requirements, easy installation and integration, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

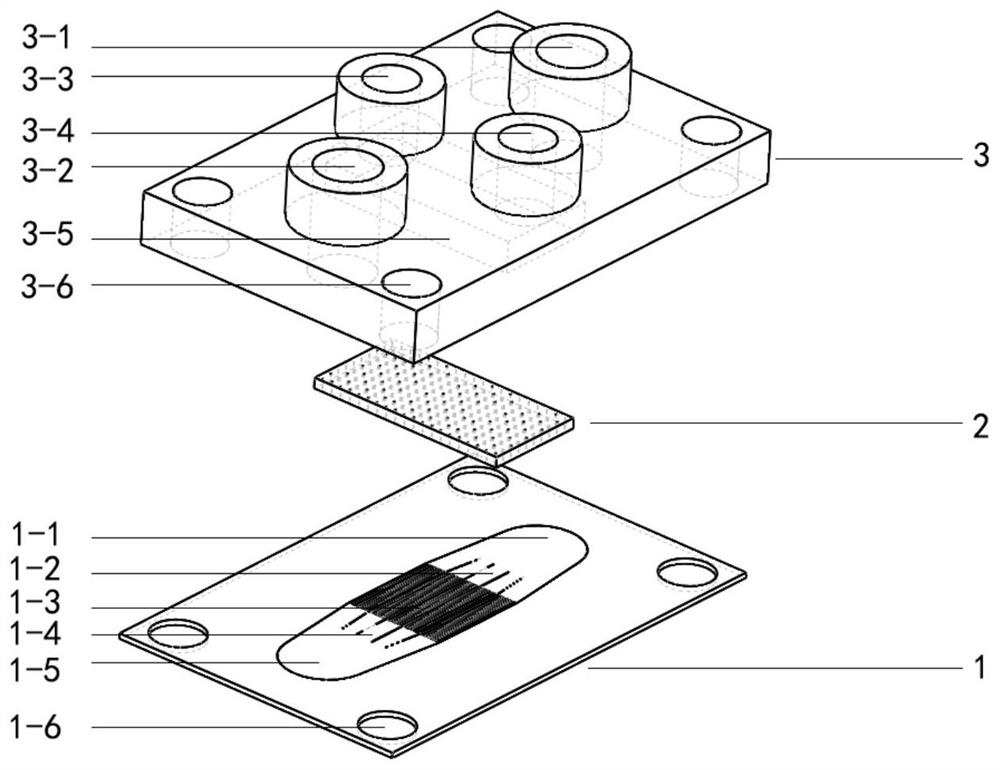

[0026] In the specific embodiment, the device is used for chip heat dissipation, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] The present invention aims to use microchannels and thin film evaporation to realize continuous, stable and efficient thin liquid film evaporation and heat exchange in combination with porous hydrophobic and breathable membranes, and solve the heat dissipation problem of ultra-high heat flux density electronic components, and proposes a high heat flux density Electronic device evaporation heat dissipation device and method.

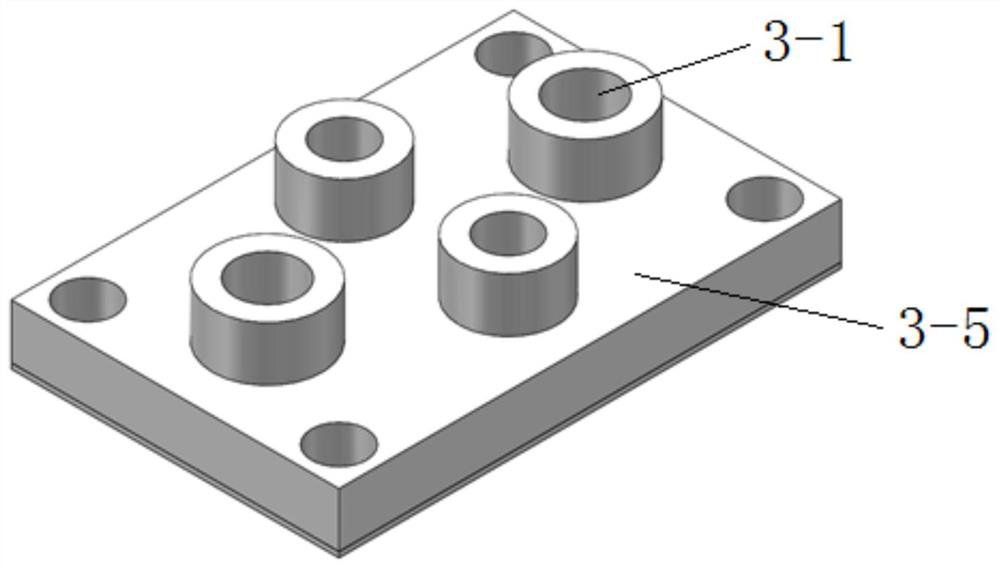

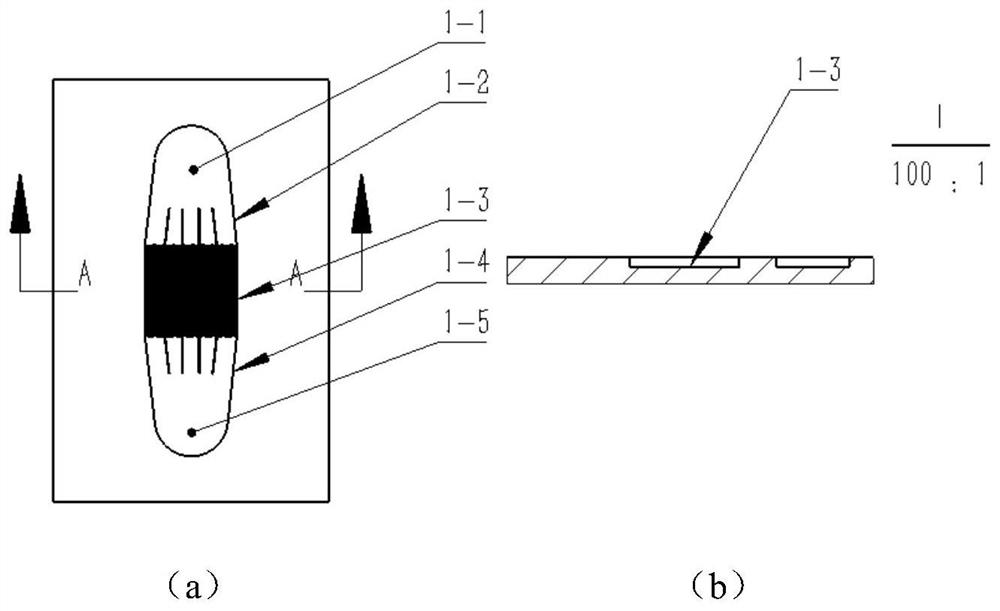

[0028] see figure 1 with figure 2 , the device is stacked from top to bottom, followed by a grooved liquid supply substrate 1, a hydrophobic and breathable film 2 and an air-liquid passage cover 3, and the hydrophobic and breathable film 2 is arranged on the grooved liquid supply substrate 1 and the air-liquid passage cover 3 Between them, the grooved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com