3D printed implant with internal channels

A technology of implants and channels, applied in the field of implants, can solve problems such as fat necrosis, reabsorption, and patient safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

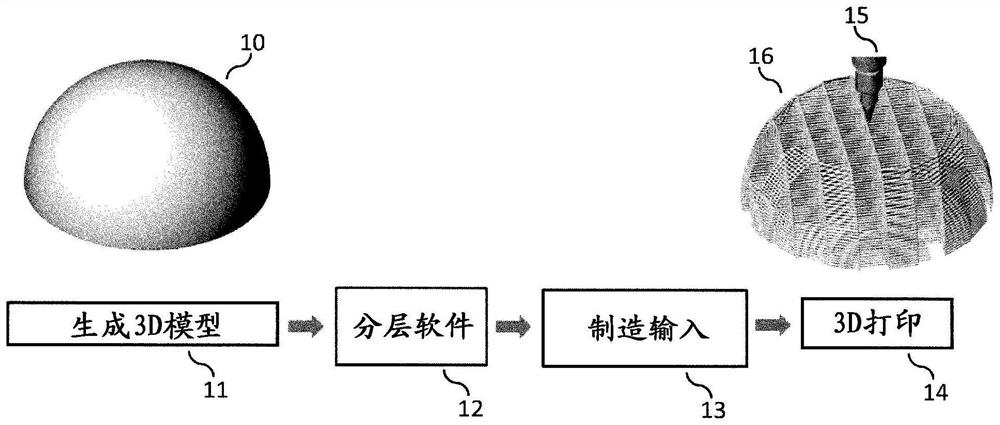

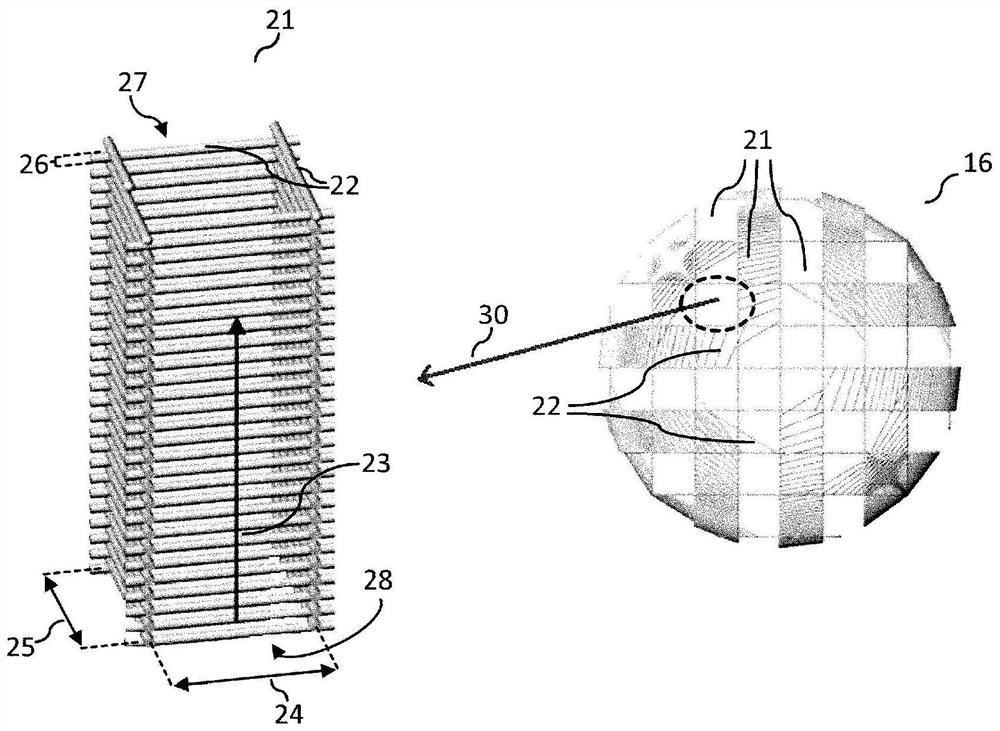

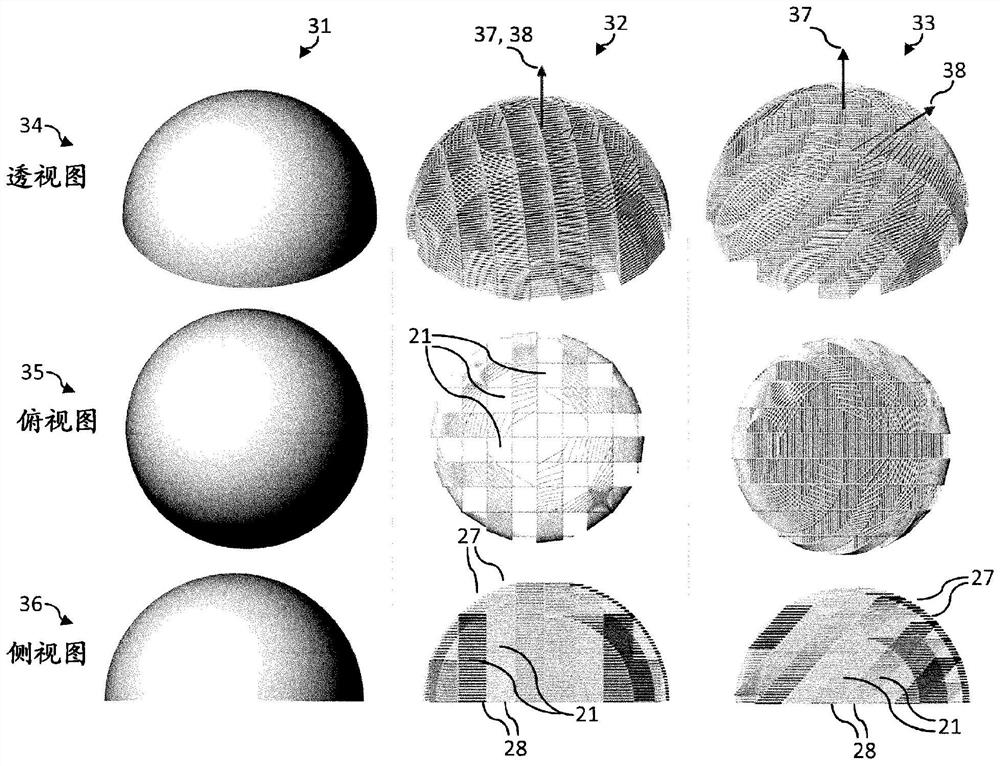

[0071] exist figure 1 In, the core steps of the printing process of the 3D implant 16 are outlined. In a first step 11, a 3D model 10 of an implant 16 is designed using computer aided design (CAD) software. At this stage, the 3D model 10 is primarily used to design the external shape of the implant 16 as desired (eg, to size the implant for a particular patient). In a second step 12, the designed 3D model is divided into layers using infill software. The second step 12 can be seen as a transition from the theoretical continuous 3D model 10 to a hierarchical definition of the continuous 3D model. These individual layers are so far undefined with respect to their internal structure (ie, the potential fill pattern for 3D printing of the layer). In a third step 13, manufacturing inputs are generated based on the layered 3D model. At this stage, an appropriate hatch pattern is selected for each layer of the 3D model 10 . The manufacturing input comprises a set of machine instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com