Formaldehyde removal method using PTC ceramic heater, and filter core

A ceramic heater, formaldehyde method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of adsorption saturation, short service life, etc., to achieve full utilization, good application prospects, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation rights of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways covered by the claims.

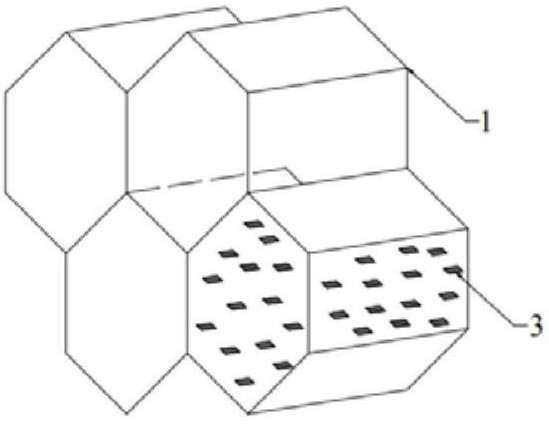

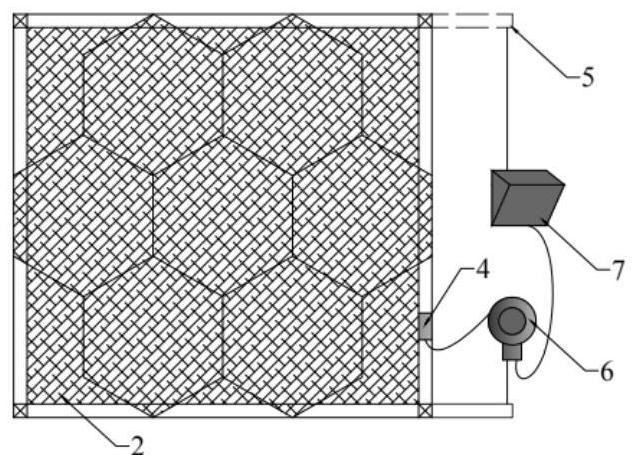

[0024] Please refer to figure 1 and figure 2 According to an embodiment of the present invention, the formaldehyde purification device includes: a PTC ceramic heater body 1, a packaging material 2, a transition metal oxide catalyst 3, a temperature-sensitive thermal resistor 4, a lead wire 5, a temperature controller 6, and a heating switch 7.

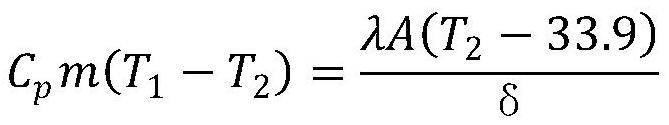

[0025] A method for purifying formaldehyde by thermocatalytic oxidation using a PTC ceramic heater of the present invention mainly utilizes the constant temperature heating of the PTC ceramic heater 1 and the characteristics of a packed bed, and adopts a more economical transition metal oxide catalyst 3 , can not only realize the catalytic decomposition of formaldehyde in the air at room temperature, but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com