Electromagnetic grading and sorting device for seeds

A sorting device, electromagnetic technology, applied in the direction of magnetic separation, seed and rhizome treatment, solid separation, etc., can solve the problems of singleness, poor magnetic separation performance, low efficiency, etc., to speed up development, improve germination rate, improve farmers income effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

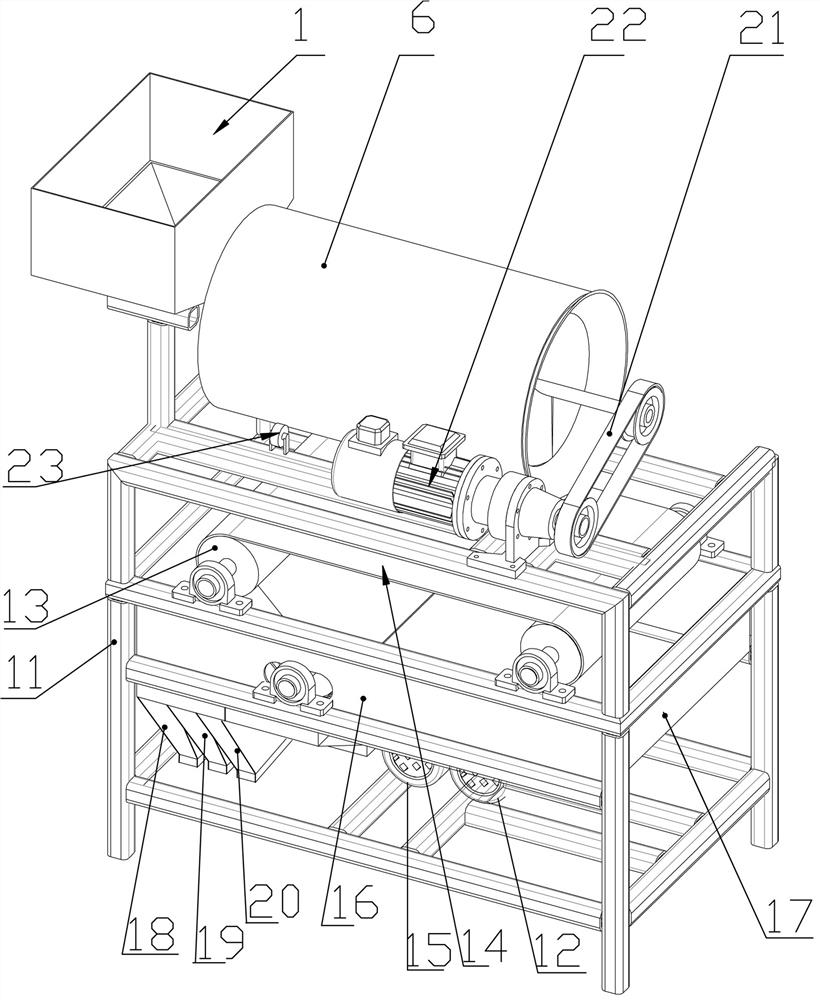

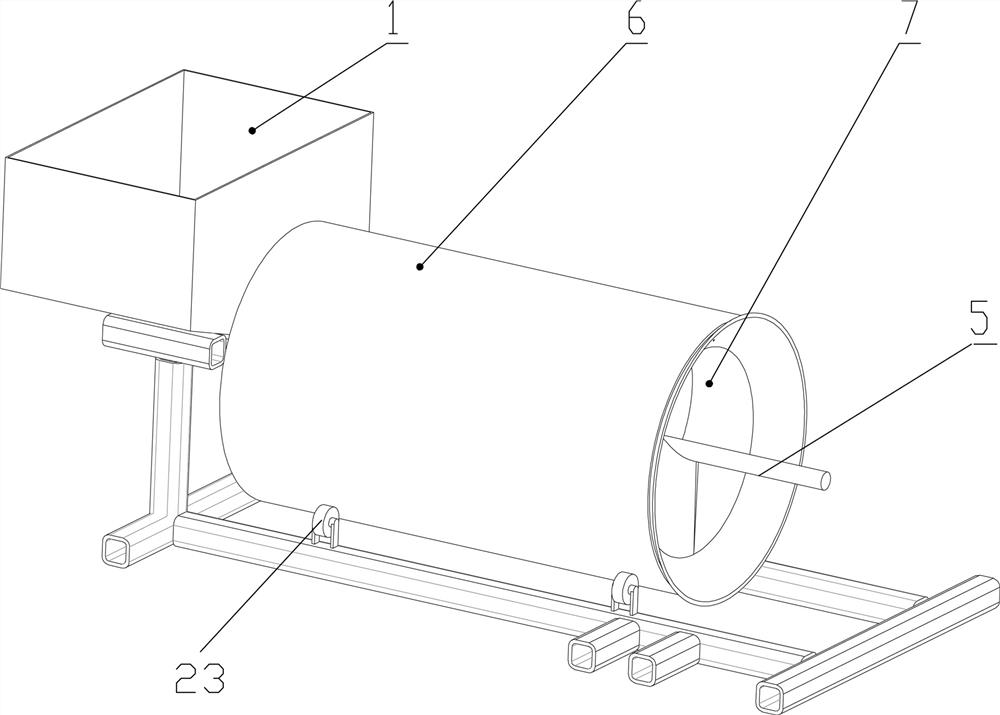

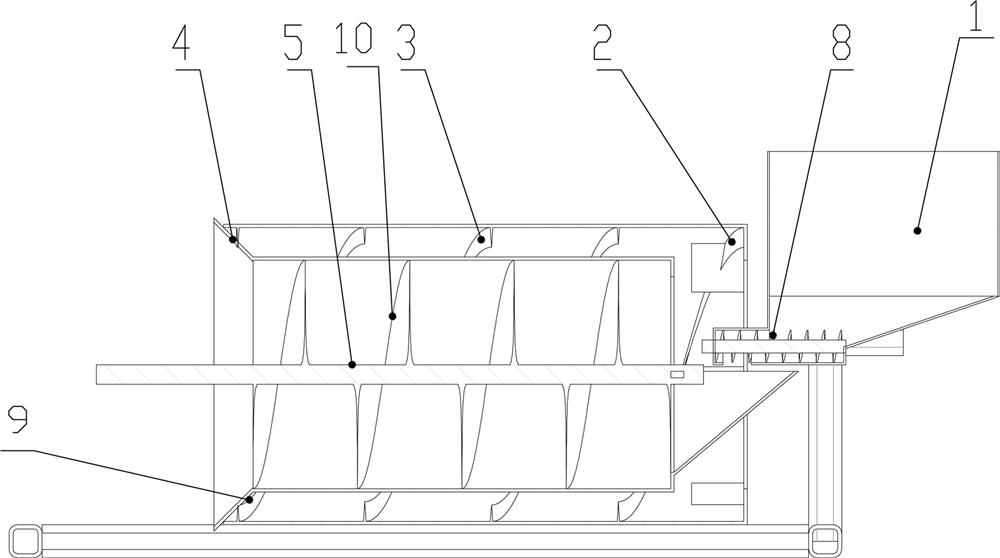

[0032] The seed electromagnetic grading and sorting device includes a feeding mechanism, a magnetic separation mechanism and a discharging mechanism, and the feeding mechanism, the magnetic separating mechanism and the discharging mechanism are sequentially connected and arranged on the skeleton 11 from top to bottom;

[0033] The feeding mechanism includes a feeding port 1, a feeding screw 8, an outer drum 6, a reverse thrust screw 3, an inner cylinder 7, a propulsion screw rod 5, an inner spiral brush 10, a first baffle 2, a second baffle 9, The screen 4, the outer drum 6 communicates with the feed port 1 on the upper side and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com