Cultivated land soil remediation system

A technology for repairing system and cultivated soil, applied in the restoration of polluted soil, machinery for lifting soil, filtering and sieving, etc. It can solve the problems of not removing pesticide residues, wasting manpower and time, affecting soil activity, etc., and avoiding heavy metal pollution , Reduce labor, small volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

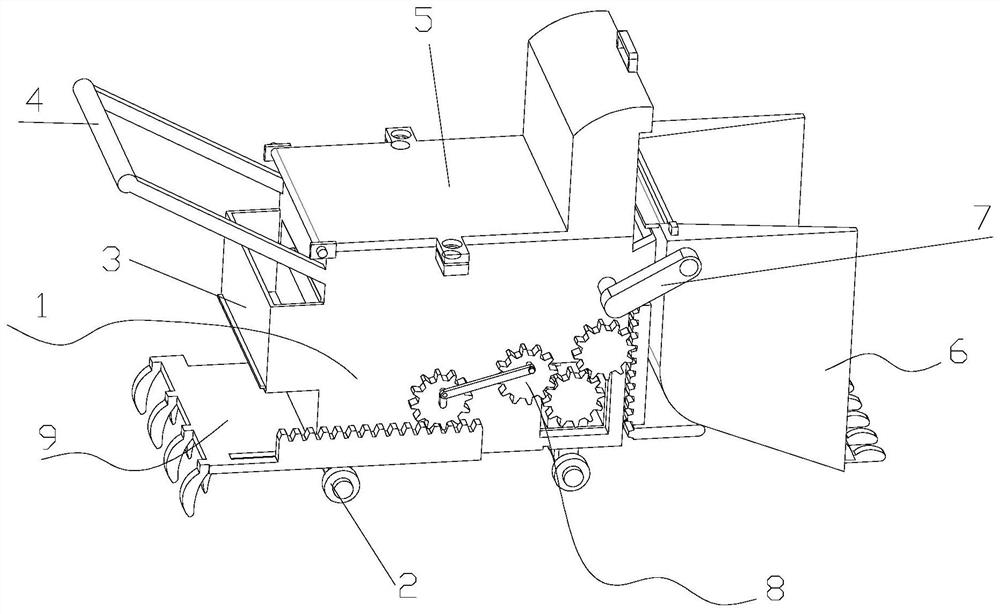

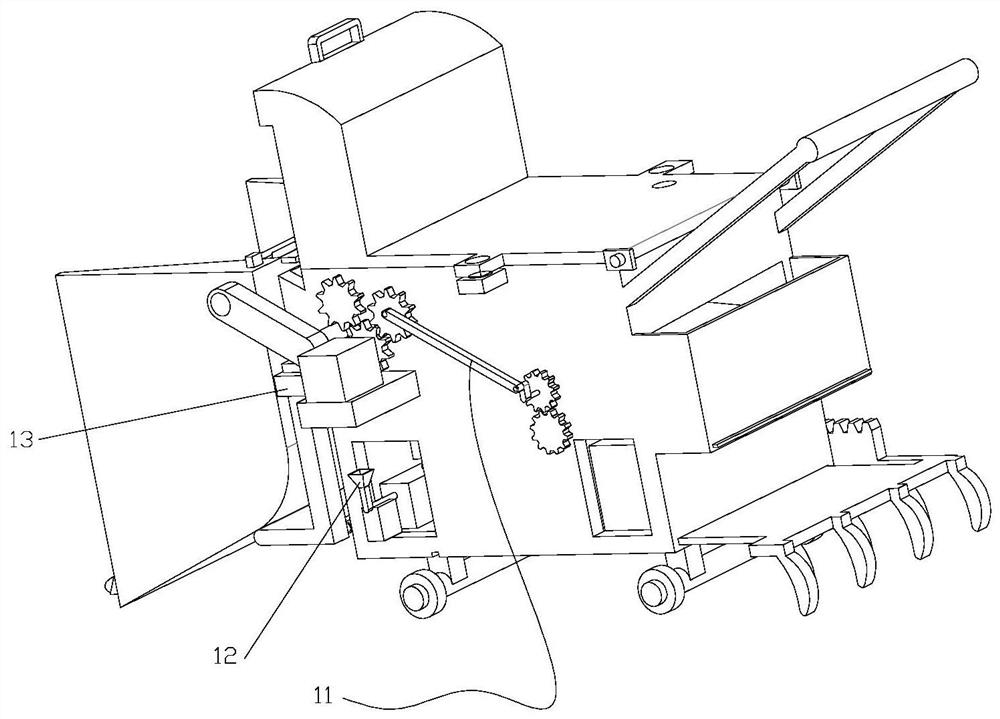

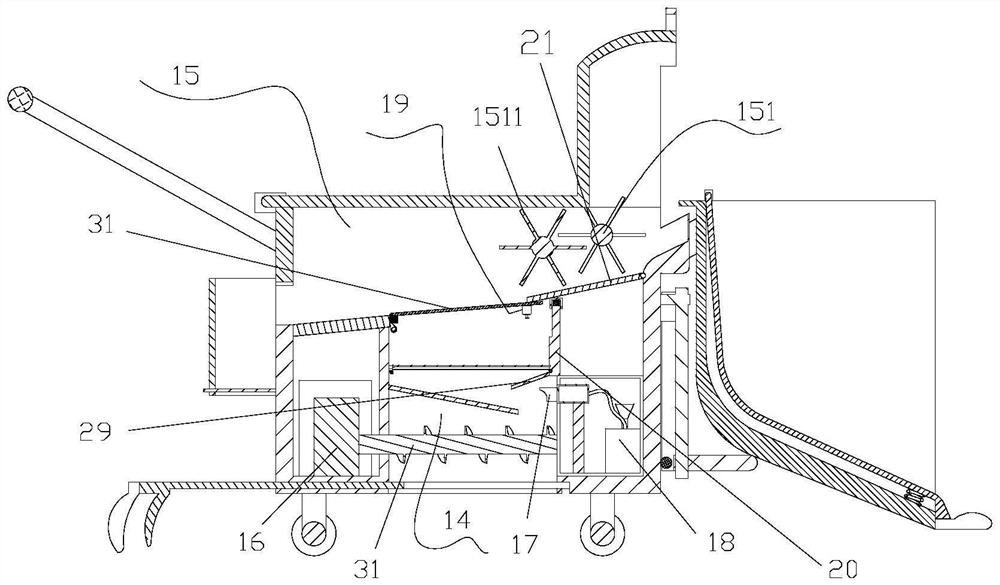

[0028] Such as Figure 1-15As shown, a cultivated land soil restoration system includes a housing 1, a wheel 2 arranged at the bottom of the housing, a garbage collection box 3 fixed on one side of the housing, a handrail 4 fixed on the housing, and a The dust cover 5, the feeder 6 on one side of the shell, the support rod 7 fixed on the shell, the first transmission mechanism 8 on the shell, and the second transmission mechanism 11 on the shell , a repair chamber 14 located inside the housing, two partitions 20 fixed inside the housing, and a preliminary screening chamber 15 located inside the housing; the preliminary screening chamber 15 includes a plurality of crushing soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com