Hydraulic combined punching and shearing machine

A punching and shearing machine, hydraulic technology, applied in the direction of metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems that V-shaped plates cannot be produced well, and the plate processing process is complicated, so as to facilitate one-time forming and reduce The effect of processing procedure and ease of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

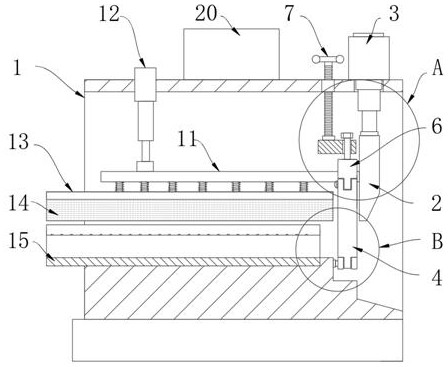

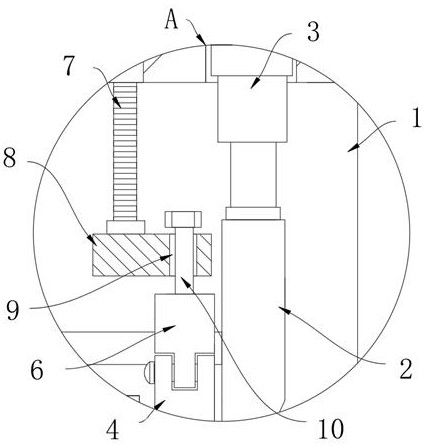

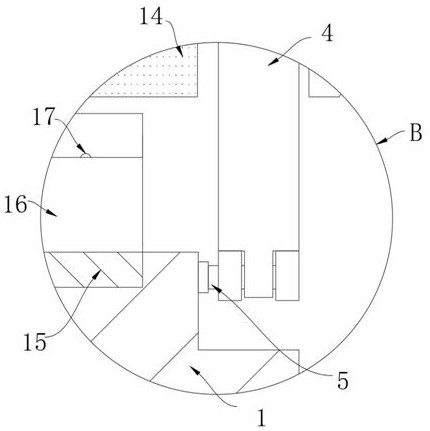

[0031] refer to Figure 1-7 , a hydraulic combined punching and shearing machine, comprising a punching and shearing body 1, the punching and shearing body 1 is a box-type structure with left and right openings, a punching and shearing tool 2 is installed at the inner right end of the punching and shearing body 1, and the punching and shearing tool 2 adopts a first hydraulic rod 3 to drive up and down displacement, and the punching and shearing lower die with adjustable angle is also arranged inside the punching and shearing machine body 1.

[0032] The right side of the punching and shearing die is attached to the left side of the punching and shearing tool 2. The punching and shearing die is composed of two corner dies 4, and the bottom ends of the two corner dies 4 are provided with through holes and pass through The positioning shaft 5 is rotatably connected to the right end of the inner bottom wall of the punching and shearing body 1, and the tops of the two corner dies 4...

Embodiment 2

[0039] refer to Figure 8-12 , Different from Embodiment 1, the right end inner top wall of the punching and shearing machine body 1 and the right side of the punching and shearing tool 2 are respectively equipped with the sensing end and the moving end of the contact switch 21, and the contact switch 21 is coupled with the controller 20.

[0040] The right end of the punching and shearing machine body 1 is equipped with a size adjustment assembly composed of a positioning frame 22, an adjustment screw 23, a wheel disc 24 and a moving plate 25, and the moving plate 25 is sleeved on the surface of the adjustment screw 23 through an internally threaded sleeve 26. Two guide rods 27 are also arranged inside the positioning frame 22 .

[0041] The bottom end of the moving plate 25 is equipped with an air control box 28, the upper surface of the air control box 28 is fixedly connected with an air intake pipe 29, the air intake pipe 29 communicates with the inner left end of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com