Positioned welding jig and welding method for assembling thin-wall feedback rod of electro-hydraulic servo valve

An electro-hydraulic servo valve and feedback rod technology, which is used in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of welding accuracy and efficiency of thin-walled feedback rods, and ensure repeatability and efficiency. The effect of satisfying seam pull strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

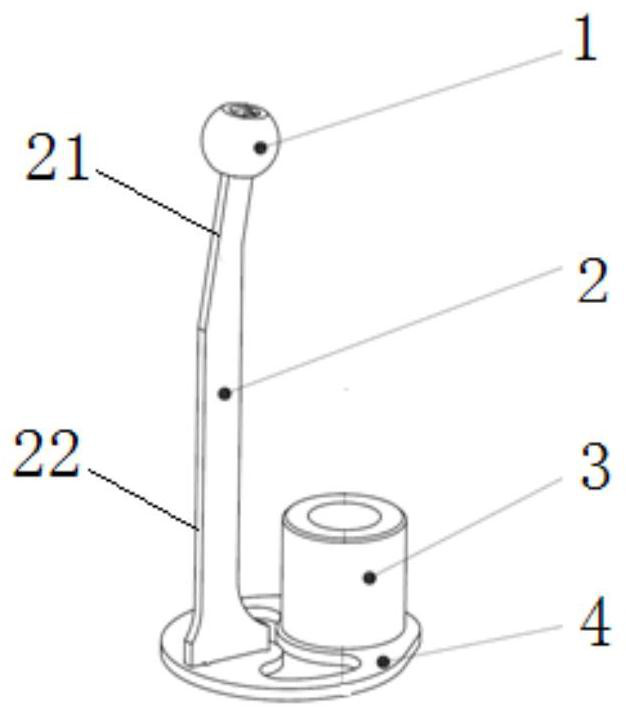

[0048] From figure 1 It can be seen that, for the feedback lever of the electro-hydraulic servo valve in this embodiment, the feedback lever seat 4 is a steel plate punched and processed by steel strip; The bent section 21 and the vertical section 22, the angle between the bent section 21 and the vertical section 22 is an obtuse angle; the steel ball 1 is welded on the end of the bending section 21 of the feedback lever; the end of the vertical section 22 of the feedback lever 2 Both the end face of the part and the casing 3 are welded on the feedback rod seat 4.

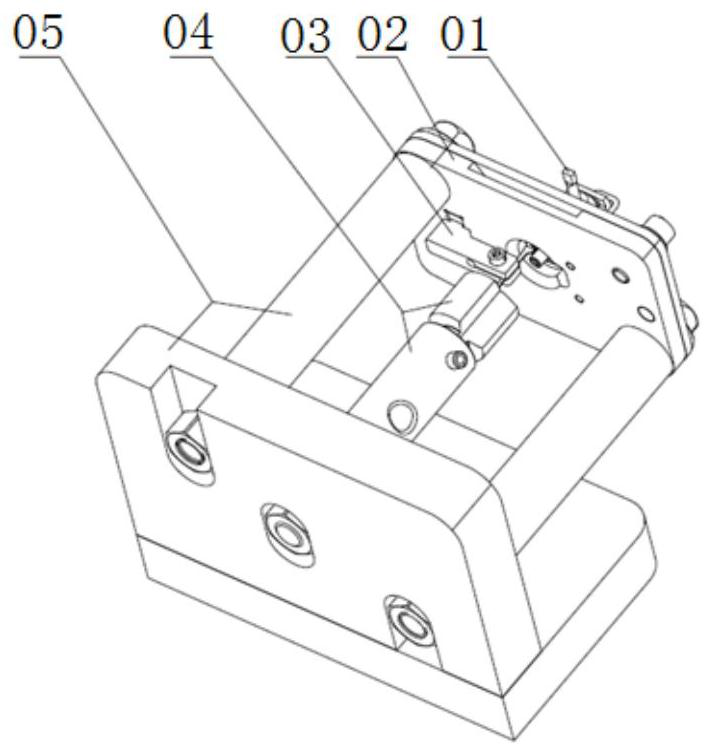

[0049] From figure 2 It can be seen that the tack welding fixture in this embodiment includes an upper positioning structure 02 , an elastic clamping structure 03 , an adjustable positioning structure 04 and a supporting structure 05 . The upper positioning structure 02 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com