Continuous dynamic membrane system operation device and working method thereof

An operating device and dynamic membrane technology, applied in chemical instruments and methods, special treatment targets, water treatment parameter control, etc., can solve problems such as multi-dissolved gas and recirculation steps, long intermittent operation time, long aeration time, etc. Achieve the effects of reducing aeration intensity and aeration time, improving filtration time and operating efficiency, and reducing operating energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail now in conjunction with accompanying drawing.

[0036] It should be noted that terms such as "upper", "lower", "left", "right", "front", and "rear" quoted in the invention are only for clarity of description, not for Limiting the practicable scope of the present invention, and the change or adjustment of the relative relationship shall also be regarded as the practicable scope of the present invention without substantive changes in the technical content.

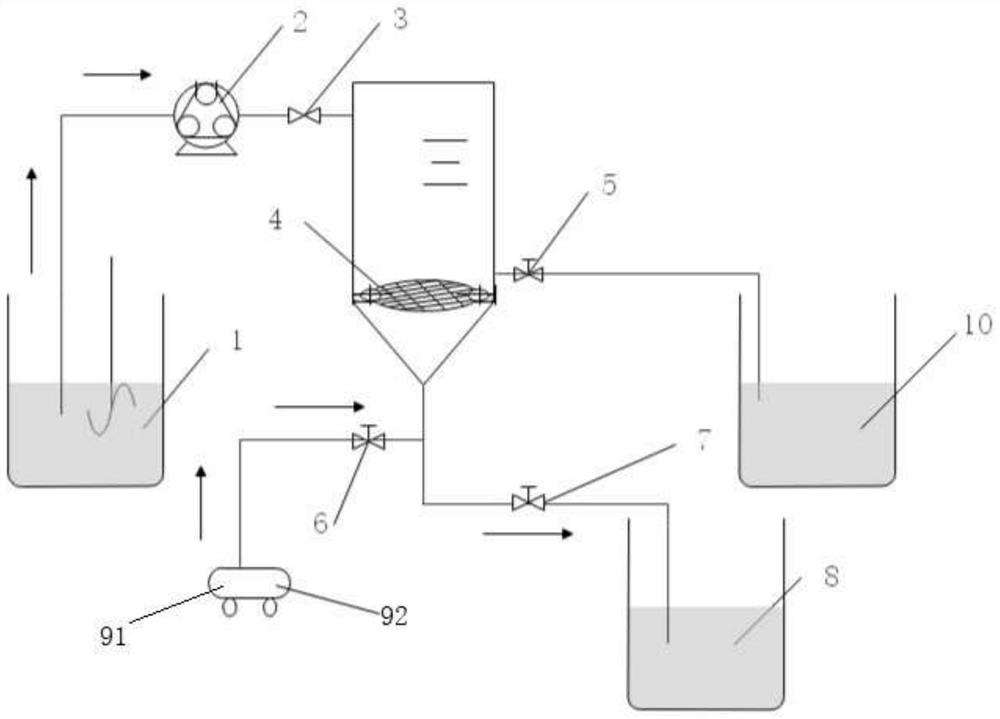

[0037] combine figure 1 , the present invention refers to a continuous dynamic membrane system operating device, the operating device is installed on the dynamic membrane filtration system, including supporting membrane 4, water inlet and sump 1, peristaltic pump 2, water inlet 3, water outlet 7, water outlet Water tank 8, backwash water pump 92, backwash air pump 91, backwash water inlet 6, backwash water outlet 5, backwash sump 10, pressure sensor and processor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com