Thermotropic anti-molten-drop aromatic liquid crystal copolyester and preparation method thereof

An anti-melting and aromatic technology, which is applied in the directions of liquid crystal materials, chemical instruments and methods, can solve the problems of increasing production costs, expensive liquid crystal polyarylate monomers, etc., and achieves a simple preparation process, excellent flame retardant and anti-dropping. Performance, the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

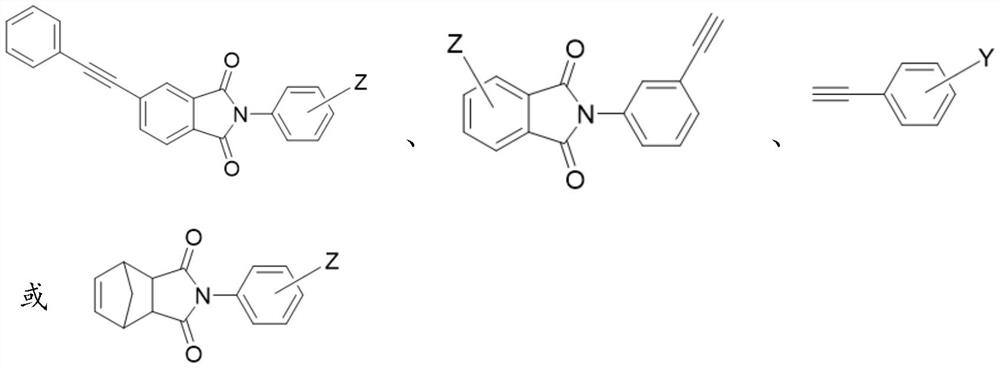

Method used

Image

Examples

Embodiment 1

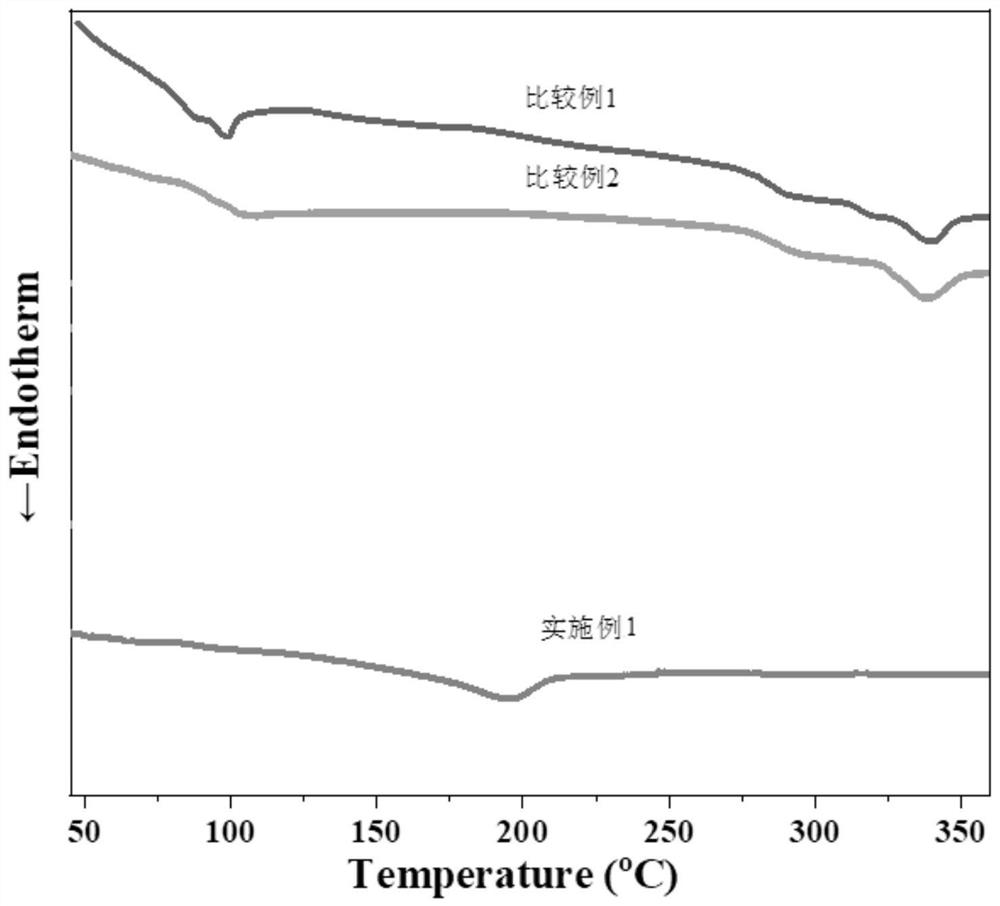

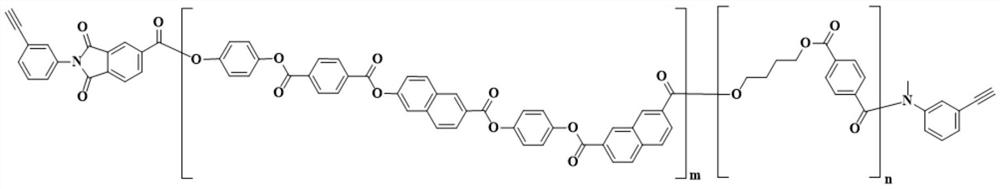

[0042] The thermotropic anti-droplet aromatic liquid crystal copolyester of this embodiment has the following chemical structural formula:

[0043]

[0044] Wherein, n=2~20, m=90~100;

[0045] Add hydroquinone, terephthalic acid, 2,7-naphthalene dicarboxylic acid, 6-hydroxy-2- naphthoic acid, PBT particles, 3-ethynyl-N-methylaniline, 2-(3-ethynylphenyl)-1,3-dioxoisoindole-5-carboxylic acid, and 180 ml of acetic anhydride in 0.2 The wt% of germanium dioxide is the catalyst. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the reaction mixture was acetylated at 140°C for 40 minutes in a quicksand bath, and then the temperature was raised to 300°C at a rate of 0.5°C / min for 2 hours of transesterification. At this point, the reaction system was slowly evacuated to a vacuum degree of 2 mbar and the temperature was set to 310° C. for 20 min. The opaque melt was coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com