Active dark blue to black dye composition and dye product

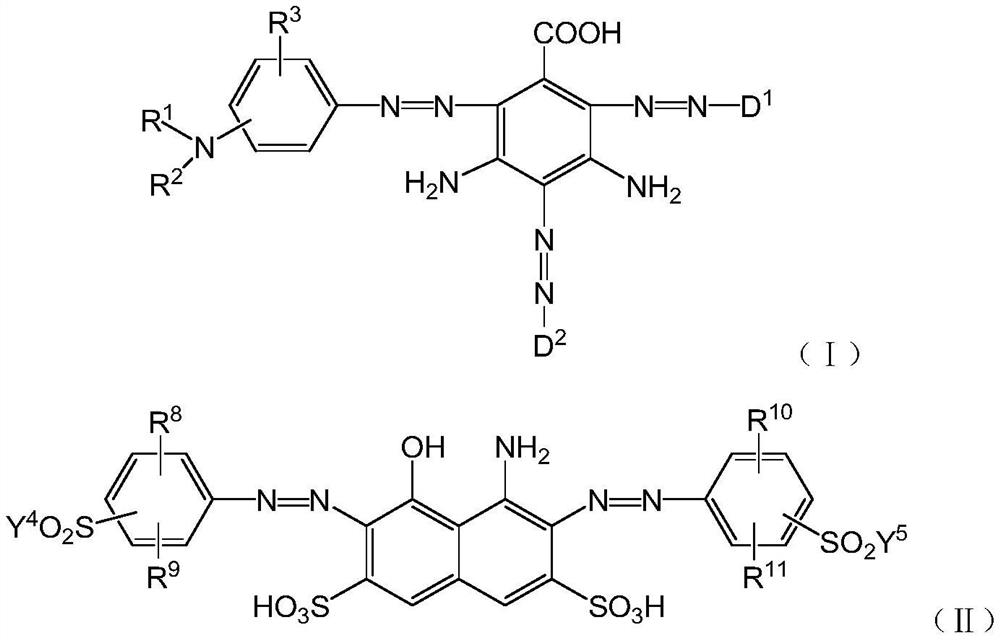

A technology of black dye and reactive navy blue, applied in the field of reactive dye compositions and dye products, can solve the problems of low washing fastness, low dyeing rate and fixation rate, poor lifting power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

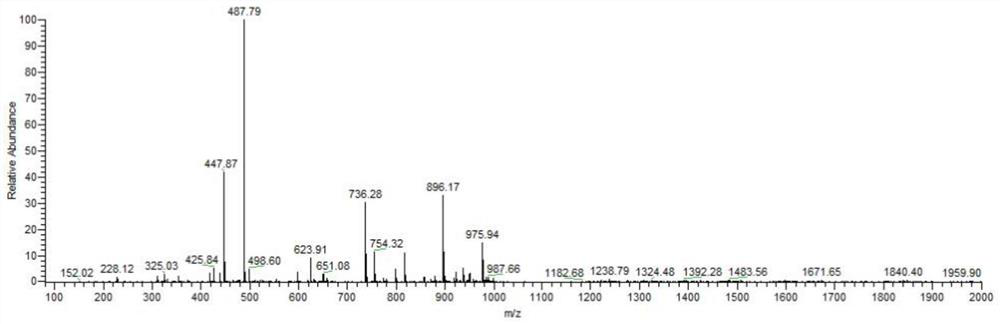

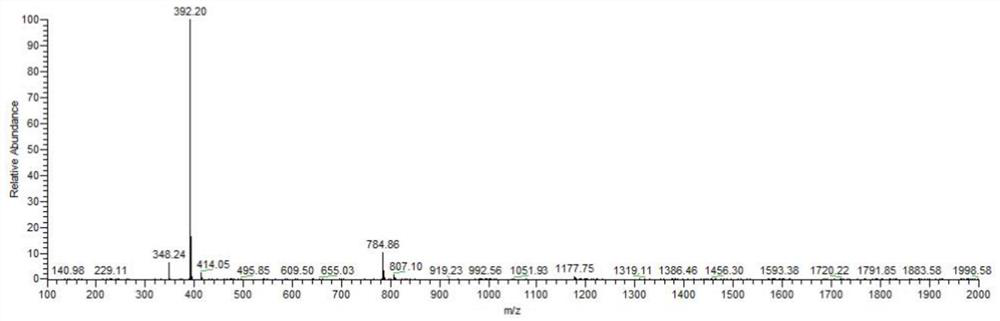

Image

Examples

Embodiment 1

[0194] (1) Diazotization:

[0195] Put 23.0g (0.1mol) of 4-acetamido-2-aminobenzenesulfonic acid into 100g of water and 100g of ice for beating for about 1 hour, then add 20g of 31% hydrochloric acid (containing 0.17mol of HCl), add 24g of 30 within 20-30min % sodium nitrite solution (containing sodium nitrite 0.104mol), control pH = 0.5-2.0, temperature T = 0-20°C for diazotization reaction for 1-2 hours, and detect with ethanol solution of 4-dimethylaminobenzaldehyde End point (that is, no discoloration within 5s). After the end point of diazo is reached, excess sodium nitrite is eliminated with sulfamic acid, and the obtained diazonium solution of 4-acetylamino-2-aminobenzenesulfonic acid is preserved for future use.

[0196] Put 56.2g (0.2mol) of para-ester (p-β-hydroxyethyl sulfone sulfate aniline) into 200g of water and 200g of ice for beating for about 1 hour, then add 35g of 31% hydrochloric acid (containing 0.3mol of HCl), and mix in 20- Add 48g of 30% sodium nitrit...

Embodiment 2~66

[0203] Referring to the preparation method of the azo dyes described in Example 1, the dye compounds with the structures shown in the following Table 1 can be prepared respectively through step-by-step diazo and coupling reactions using intermediate raw materials well known in the art.

[0204] Table 1

[0205]

[0206]

[0207]

[0208]

[0209]

[0210]

[0211]

[0212]

[0213]

[0214]

[0215]

[0216]

[0217]

[0218]

[0219]

[0220]

Embodiment 67

[0222] Mechanically mix 25 parts of the dye of formula (I-1), 75 parts of the dye of formula (II-1) and 10 parts of antalanthum, and the obtained composite dye is dyed black in cotton by conventional exhaust dyeing method, and is particularly resistant to washing and staining. The color fastness to staining of nylon and wool is above grade 4 (refer to ISO 105 C10-2006), and the lifting power and color fixing rate are excellent (refer to GB / T21875-2016 and GB / T2391-2014).

[0223]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com