Wide-temperature-range gap compensation roller assembly with guiding, damping and supporting effects

A technology of vibration damping support and clearance compensation, applied in the direction of spring/shock absorber, vibration suppression adjustment, shaft and bearing, etc., can solve the influence of the transmission accuracy and transmission performance of the mechanism, cannot meet the mechanism clearance compensation, and the guide rail cannot be lubricated, etc. problems, to achieve the effect of no major changes in the guiding accuracy, improved motion adaptability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

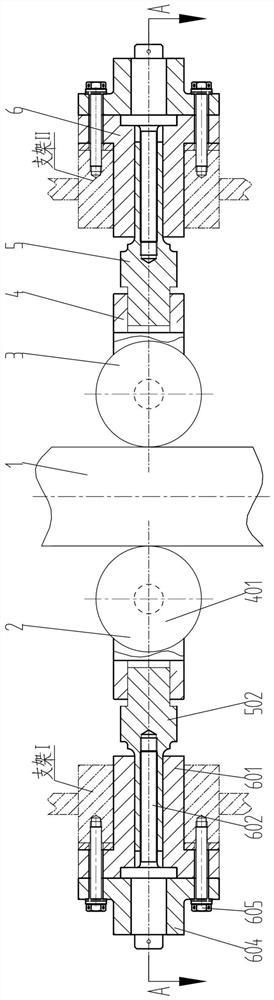

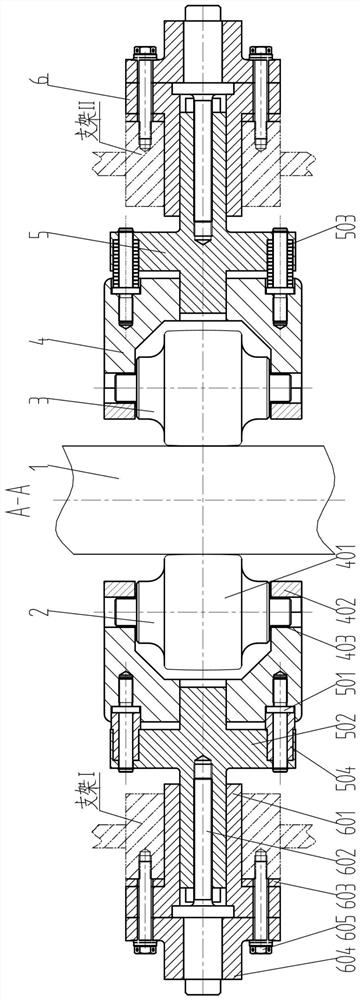

Method used

Image

Examples

Embodiment 1

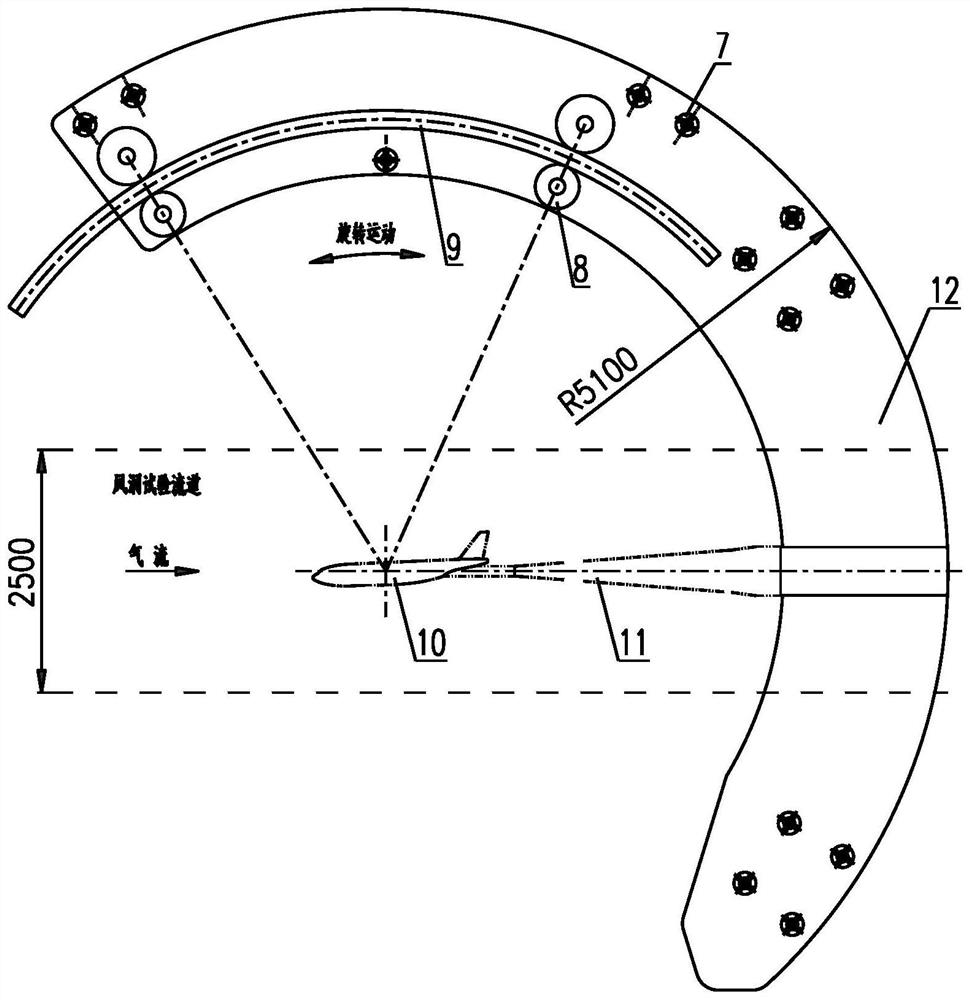

[0047] Such as image 3 As shown, multiple sets of roller assemblies 7 are installed on both sides of the arc-shaped support plate 12 of the wind tunnel, and the arc-shaped support plate 12 is pressed against the positioning roller assembly 2 and the pressing roller assembly 3, and the multiple sets of roller assemblies 7 reduce the Lateral swing of arc support plate 12. The radius of the arc guide rail 9 of this wind tunnel is 4000mm, and the test model 10 is installed on the rotation center of the arc guide rail 9, and the test model 10 is fixed on the arc support plate 12 through the tail support rod 11. When the arc support plate 12 When moving along the arc guide rail 9 under the action of the rotary guide assembly 8, the arc support plate 12 drives the angle of attack of the test model 10 to continuously change in a wide range, and the stroke of the rotary guide assembly 8 is 2100mm.

[0048] In a wide temperature range, the test model 10 was tested under different airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com