Debugging diagnosis system and method for radar liquid level meter

A technology of radar liquid level gauge and diagnostic system, which is applied in the direction of testing/calibration devices, liquid/fluid solid measurement, measuring devices, etc. It can solve the problems of harsh maintenance windows, taking up the main line of unit overhaul time, and lack of methods to guide installation, etc. To achieve the effect of convenient on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

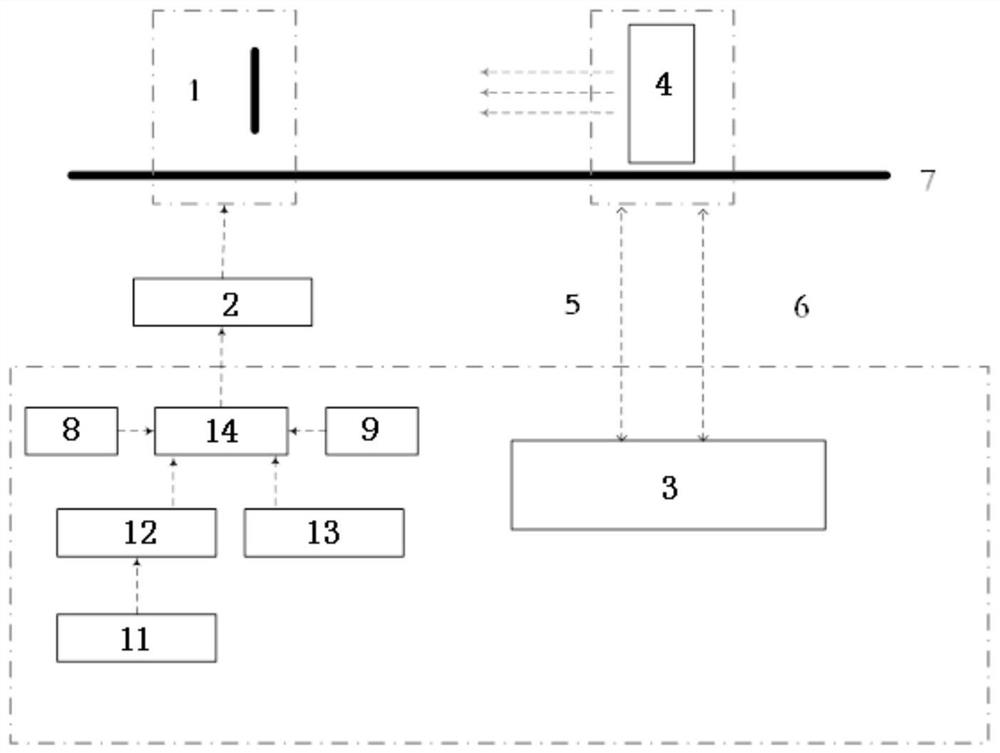

[0024] A debugging and diagnosing system for a radar liquid level gauge, comprising a debugging and diagnosing terminal system, a manual automatic control system, a radar wave reflector 1 and a reflector actuator 2; the radar wave reflector 1 is installed on a guide rail 7;

[0025] The debugging diagnosis terminal system includes a debugging diagnosis terminal 3 and a radar level gauge 4. The debugging diagnosis terminal 3 is respectively connected to the radar level gauge 4 through a communication cable 5 and a power supply and signal cable 6. The radar level gauge 4 is installed on the guide rail 7, and the power supply And the signal cable 6 provides 24VDC working power for the radar level gauge 4. At the same time, the power supply and signal cable 6 is also used as a signal loop cable to connect the output signal of the radar level gauge 4 in series to the debugging and diagnosis terminal 3, and the communication cable 5 is It is used to realize the data transmission betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com