Silver-plated copper strip wrapping structure of stable-phase cable and manufacturing equipment and preparation method thereof

A silver-plated copper tape, phase-stable cable technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of poor internal structural stability of the cable, large attenuation changes during vibration, and large phase changes, and achieve physical length. and electrical parameters remain stable, phase stability is improved, and tightness is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

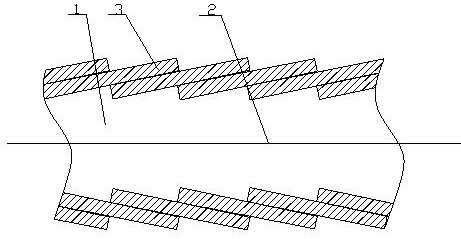

[0036] The phase-stable cable has a silver-plated copper tape wrapping structure, including an inner conductor 2, the inner conductor 2 is wrapped with an insulating layer 1, the insulating layer 1 is provided with a silver-plated copper tape 3, and the silver-plated copper tape 3 and the insulating layer 1 are provided. There is an angle of inclination, and the silver-plated copper strips 3 are stacked and stacked sequentially. There is another layer of silver-plated copper strips under the upwardly inclined side of the silver-plated copper strips 3. The outer and inner surfaces of the silver-plated copper strips are both serrated. shape.

[0037] One end of the silver-plated copper strip is located below the previous circle of silver-plated copper strip, and the other end is located above the next circle of silver-plated copper strip.

[0038] The covering rate of the silver-plated copper tape is 51%. The main performance indicators of the silver-plated copper tape material ...

Embodiment 2

[0058] The phase-stable cable has a silver-plated copper tape wrapping structure, including an inner conductor 2, the inner conductor 2 is wrapped with an insulating layer 1, the insulating layer 1 is provided with a silver-plated copper tape 3, and the silver-plated copper tape 3 and the insulating layer 1 are provided. There is an angle of inclination, and the silver-plated copper strips 3 are stacked and stacked sequentially. There is another layer of silver-plated copper strips under the upwardly inclined side of the silver-plated copper strips 3. The outer and inner surfaces of the silver-plated copper strips are both serrated. shape.

[0059] One end of the silver-plated copper strip is located below the previous circle of silver-plated copper strip, and the other end is located above the next circle of silver-plated copper strip.

[0060] The covering rate of the silver-plated copper tape is 52%. The main performance indicators of the silver-plated copper tape material ...

Embodiment 3

[0080] The phase-stable cable has a silver-plated copper tape wrapping structure, including an inner conductor 2, the inner conductor 2 is wrapped with an insulating layer 1, the insulating layer 1 is provided with a silver-plated copper tape 3, and the silver-plated copper tape 3 and the insulating layer 1 are provided. There is an angle of inclination, and the silver-plated copper strips 3 are stacked and stacked sequentially. There is another layer of silver-plated copper strips under the upwardly inclined side of the silver-plated copper strips 3. The outer and inner surfaces of the silver-plated copper strips are both serrated. shape.

[0081] One end of the silver-plated copper strip is located below the previous circle of silver-plated copper strip, and the other end is located above the next circle of silver-plated copper strip.

[0082] The covering rate of the silver-plated copper strip is 48%. The main performance indicators of the silver-plated copper strip materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com