Propylene carbonate electrolyte as well as preparation method and application thereof

A technology of propylene carbonate and electrolyte, which is applied in the field of propylene carbonate electrolyte and its preparation, can solve problems such as poor cycle performance, damage to graphite electrode structure, and impact on battery performance, so as to improve performance, inhibit embedded graphite, and better interact The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a kind of preparation method of the propylene carbonate electrolyte described in above-mentioned technical scheme, comprises the following steps:

[0061] In the glove box, mix propylene carbonate and chain carbonate evenly, then slowly add lithium salt, add the additive after the lithium salt is completely dissolved, and obtain propylene carbonate electrolyte after shaking well;

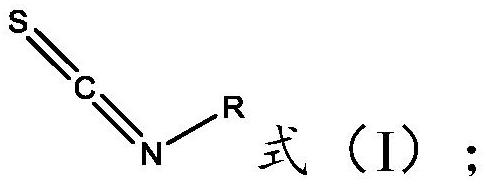

[0062] The additive is an isothiocyanate compound.

[0063] In the present invention, the glove box preferably adopts an argon atmosphere with a moisture content of less than 10 ppm.

[0064] In the present invention, the propylene carbonate, chain carbonate, lithium salt and additives are the same as those in the above technical solution, and will not be repeated here. In the present invention, the additive is an isothiocyanate compound.

[0065] In the present invention, the whole operation process ensures that the temperature of the mixed system does n...

Embodiment 1

[0075] In an argon atmosphere glove box with moisture less than 10ppm, mix 8.4g propylene carbonate (PC) and 3.2g dimethyl carbonate (DMC) evenly, then slowly add 1.5g lithium hexafluorophosphate (LiPF 6 ), the whole operation process ensures that the temperature of the mixing system does not exceed the decomposition temperature (30°C) of lithium hexafluorophosphate, and after the lithium salt is completely dissolved, add 0.655 g of ethyl isothiocyanate, and shake well to obtain a propylene carbonate electrolyte;

[0076] The mass ratio of each component in the propylene carbonate electrolyte is as follows: Lithium salt LiPF 6 is 11wt%, PC is 61wt%, DMC is 23wt%, and additive ethyl isothiocyanate is 5wt%.

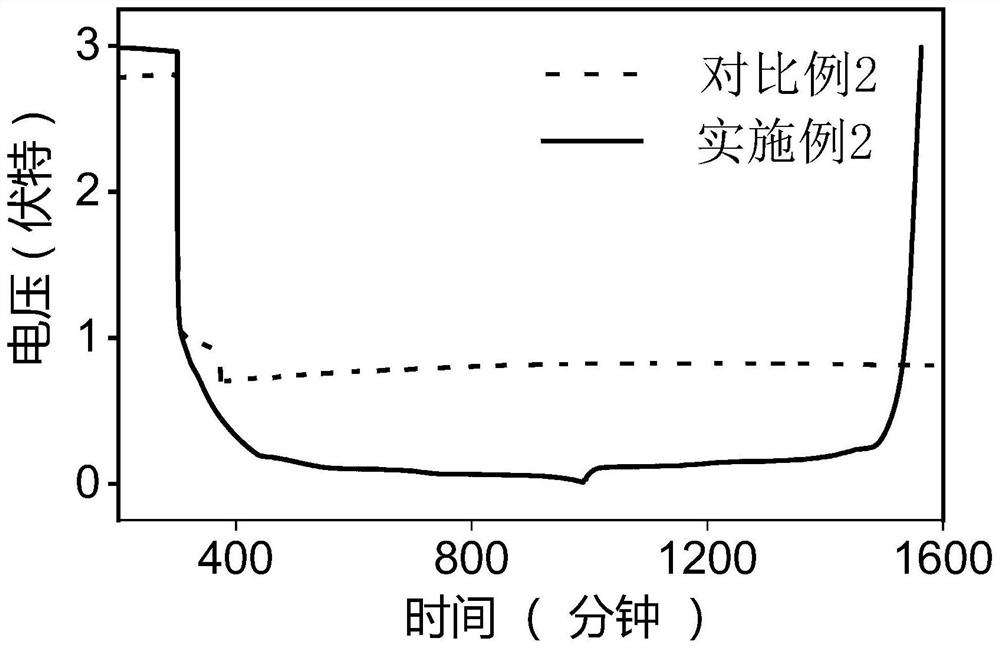

Embodiment 2

[0078] Adopt the preparation method that embodiment 1 provides to obtain propylene carbonate electrolyte;

[0079] The mass ratio of each component in the propylene carbonate electrolyte is as follows: Lithium salt LiPF 6 is 11wt%, PC is 87wt%, and additive ethyl isothiocyanate is 2wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com