Light guide plate encapsulation member and planar light source device or lighting device using same

A technology for light guide components and sealing components, applied in lighting devices, planar/plate-shaped light guides, electric light sources, etc., can solve problems such as interference fringes and damage to optical properties, and achieve embedding suppression, high smoothness, and sufficient bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0153] Hereinafter, although this invention is demonstrated based on an Example and a comparative example, this invention is not limited to the content of an Example.

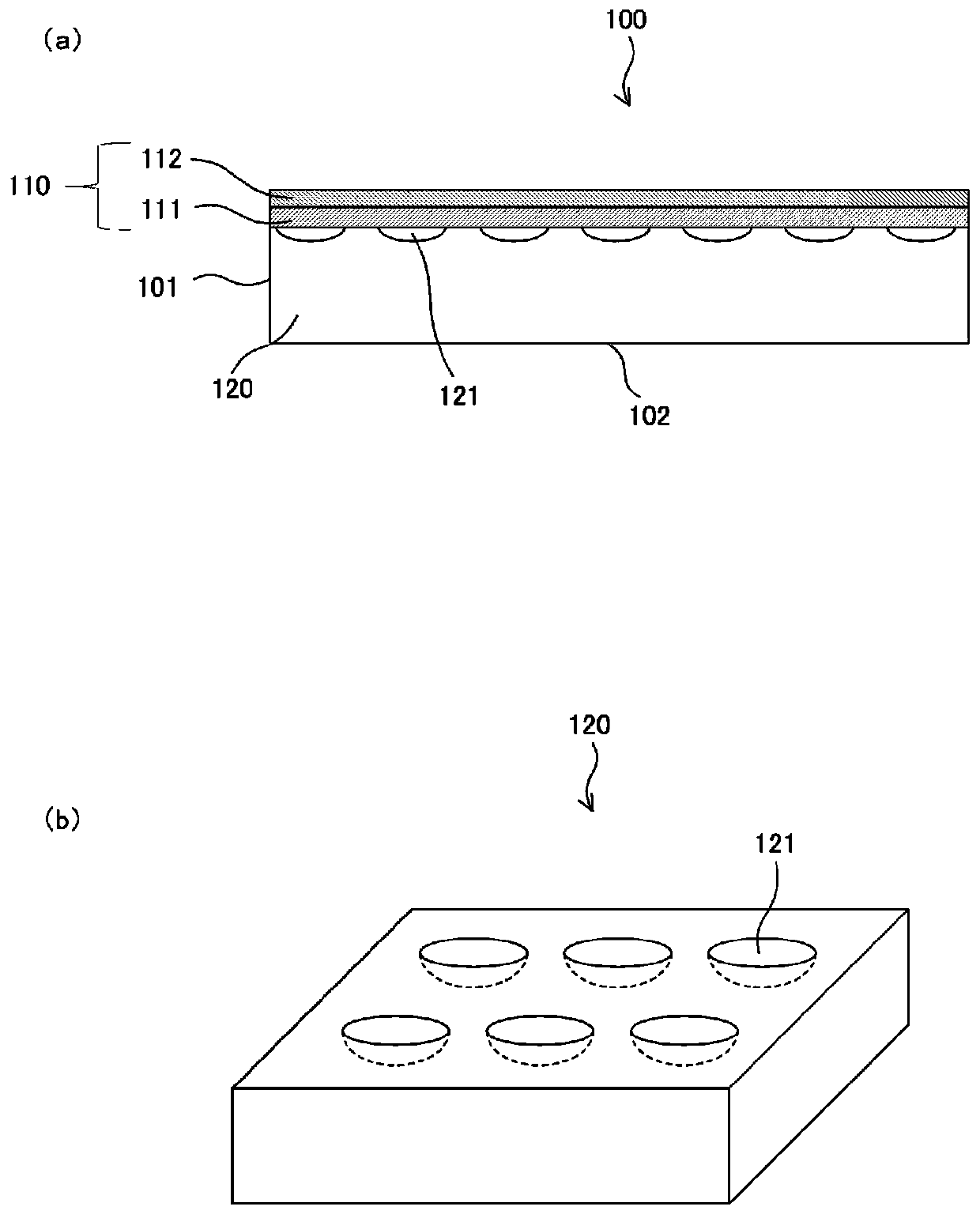

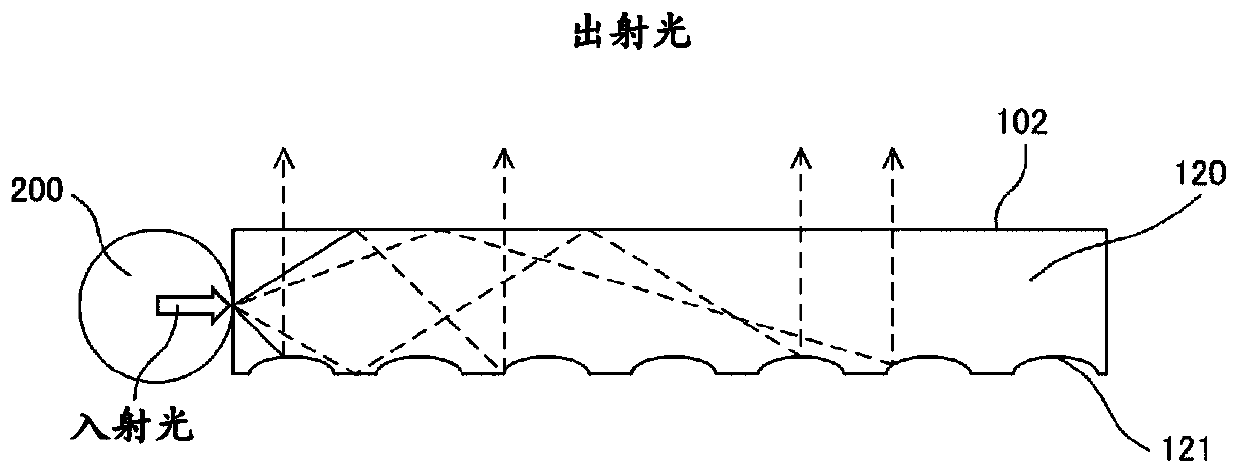

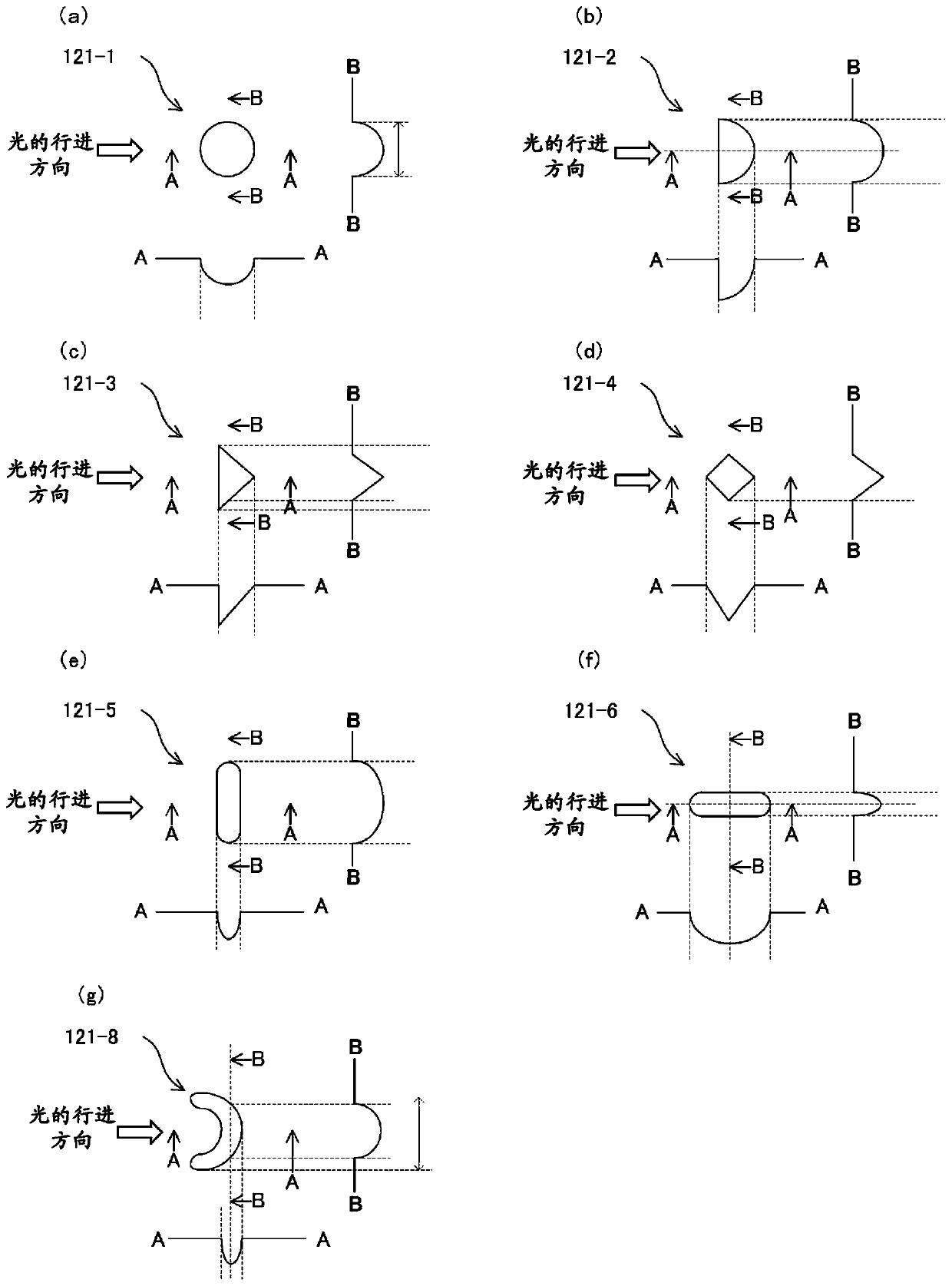

[0154] On a 2mm thick PMMA sheet with a size of 130mm x 90mm, UV curable acrylic resin (containing a photopolymerization initiator) is used to form a coating layer with a thickness of 10 μm, and a convex lens-shaped dot shape with a diameter of about 40 μm and a height of about 10 μm is used. mold (convex lens density: about 100 / mm 2 ) was pressurized while irradiating UV light from the surface of the PMMA sheet on the opposite side to the coating layer to cure, thereby producing a light guide member having a concave portion used in the present invention. The surface of the obtained light guide member was observed with a laser microscope, and it was confirmed that about 100 pieces / mm 2 There is a concave lens-shaped dot-shaped light guide member having a concave portion with a size (diameter) of about 40 μm an...

manufacture example 1

[0156] Synthesis of Compound 1:

[0157] 196.29 g (1 mol) of tricyclodecane dimethanol and 22.828 g (0.2 mol) of ε-caprolactone were added to the flask, the temperature was raised to 120° C., and 50 ppm of monobutyltin oxide was added as a catalyst. Then, the reaction was carried out under nitrogen flow until the remaining ε-caprolactone was less than 1% in gas chromatography to obtain diol (1).

[0158] 444.56 g (2 moles) of isophorone diisocyanate was added to another flask, and 424.57 g (1 mole) of diol (1) was added at a reaction temperature of 70° C., and added when the remaining isocyanate group became 5.7%. 232.24 g (2 moles) of 2-hydroxyethyl acrylate and 0.35 g of dibutyltin laurate were reacted until the remaining isocyanate group was 0.1%, and urethane acrylate (compound 1) was obtained as a monomer.

manufacture example 2

[0160] Except that the amount of ε-caprolactone used was changed from 0.2 mol to 2 mol, the same procedure as in Production Example 1 was carried out to obtain Compound 2 as a monomer (the two ends of Compound 2 are acryloyl groups, except that it is the same as The same applies to the structure in which m is 1 in the general formula (1a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com