Glass-ceramic articles with improved stress profiles

A technology of glass ceramics and stress distribution, applied in the field of glass ceramic products with improved stress distribution, which can solve the problems of slow diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] Glass-ceramic articles were formed from the above-mentioned lithium-based glass-ceramic substrates by a two-step ion exchange treatment.

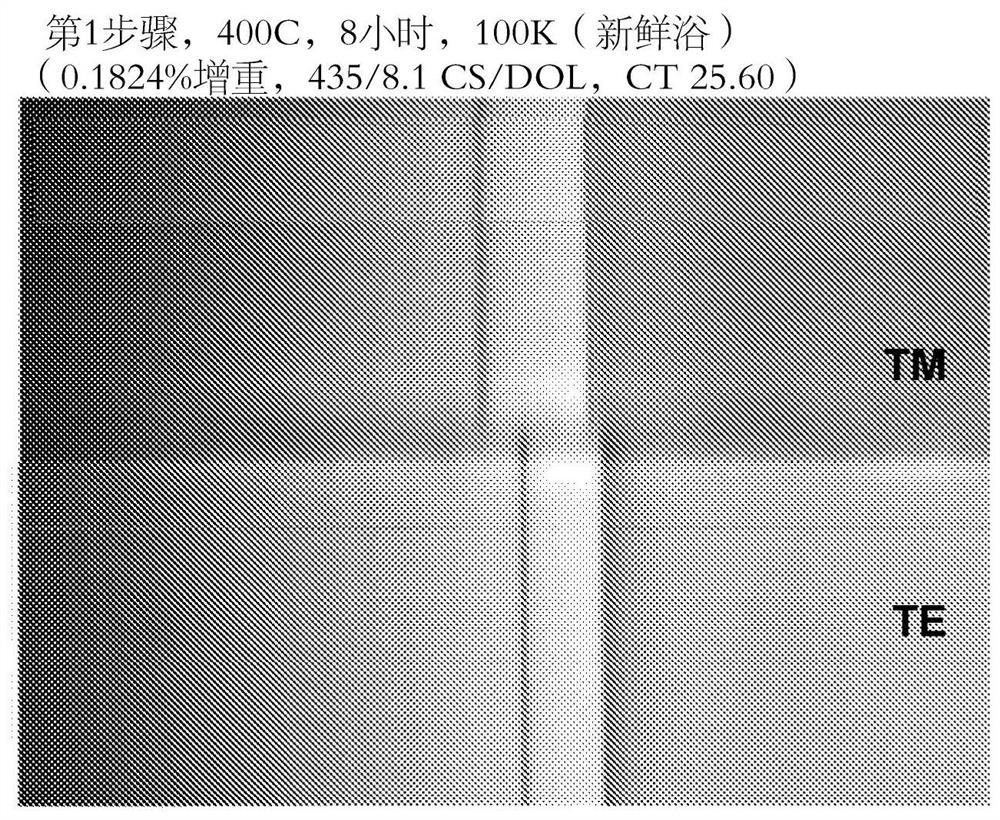

[0147] The first IOX bath is 100 wt% KNO 3 , and 0.5% by weight (of the bath) of NaNO was added to the bath 2 Dose to improve bath chemistry. 10X at 460°C for 8 hours. After the first IOX with: 0.1824% weight gain, 435 MPa compressive stress (CS), depth of layer (DOL) for K 8.1 microns (depth of inflection point), 25.60 MPa maximum central tension (CT). figure 2 are images of TM and TE guided mode spectral fringes after the first 10X treatment.

[0148] The substrate is then exposed to a second 10× bath, which is 90% by weight KNO 3 and 10 wt% NaNO 3 , and contains (of the bath) 0.5% by weight of NaNO 2 dose. The second 10X was at 430°C for 8 hours. Has: 0.3463% weight gain, 339 MPa CS, DOL for K 9.4 microns, 39.75 MPa maximum central tension (CT). image 3 are images of the TM and TE guided mode spectral fringes of the res...

Embodiment 2

[0150] Glass-ceramic articles were formed from the above-mentioned lithium-based glass-ceramic substrates by a two-step ion exchange process in the presence of lithium in the IOX process.

[0151] The first IOX bath is 100 wt% KNO 3 , to which 0.02% by weight (of the bath) of LiNO was added 3 Dose and 0.5 wt% NaNO 2 dose. The first 10X was at 460°C for 8 hours. Has a 0.1219% weight gain and a CT of 17.36 MPa. Figure 4 are images of TM and TE guided mode spectral fringes after the first 10X treatment.

[0152] The substrate is then exposed to a second 10× bath, which is 90% by weight KNO 3 and 10 wt% NaNO 3 , to which 0.02 wt% (of the bath) of LiNO was added 3 Dose and 0.5 wt% NaNO 2 dose. The second 10X was at 430°C for 8 hours. Has a 0.3587% weight gain and a CT of 45.78 MPa. Figure 5 are images of the TM and TE guided mode spectral fringes of the resulting glass-ceramic article. There are two stripes, which enable proper process control over bath composition, b...

Embodiment 3

[0154] Glass-ceramic articles were formed from the above-mentioned lithium-based glass-ceramic substrates by a two-step ion exchange process in the presence of lithium in the IOX process.

[0155] The first IOX bath is 100 wt% KNO 3 , to which 0.02% by weight (of the bath) of LiNO was added 3 Dose and 0.5 wt% NaNO 2 dose. The first 10X was at 460°C for 8 hours. Has a CT of 15.97MPa. Figure 6 are images of TM and TE guided mode spectral fringes after the first 10X treatment. Figure 7 is the resulting stress profile (stress (MPa) vs. position (microns) plot) after the first 10× treatment for half the substrate thickness. exist Figure 7 , notice the presence of spikes.

[0156] The substrate is then exposed to a second 10× bath, which is 90% by weight KNO 3 and 10 wt% NaNO 3 , to which 0.02 wt% (of the bath) of LiNO was added 3 Dose and 0.5 wt% NaNO 2 dose. The second 10X was at 460°C for 10 hours. Has a CS of 303 MPa, a potassium DOL (depth of inflection point) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com