Agricultural stubble treatment device

A processing device and stubble technology, applied in the field of agricultural equipment, can solve problems such as unfavorable agricultural production, time-consuming and other problems, and achieve the effects of being beneficial to agricultural production, convenient for decay, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

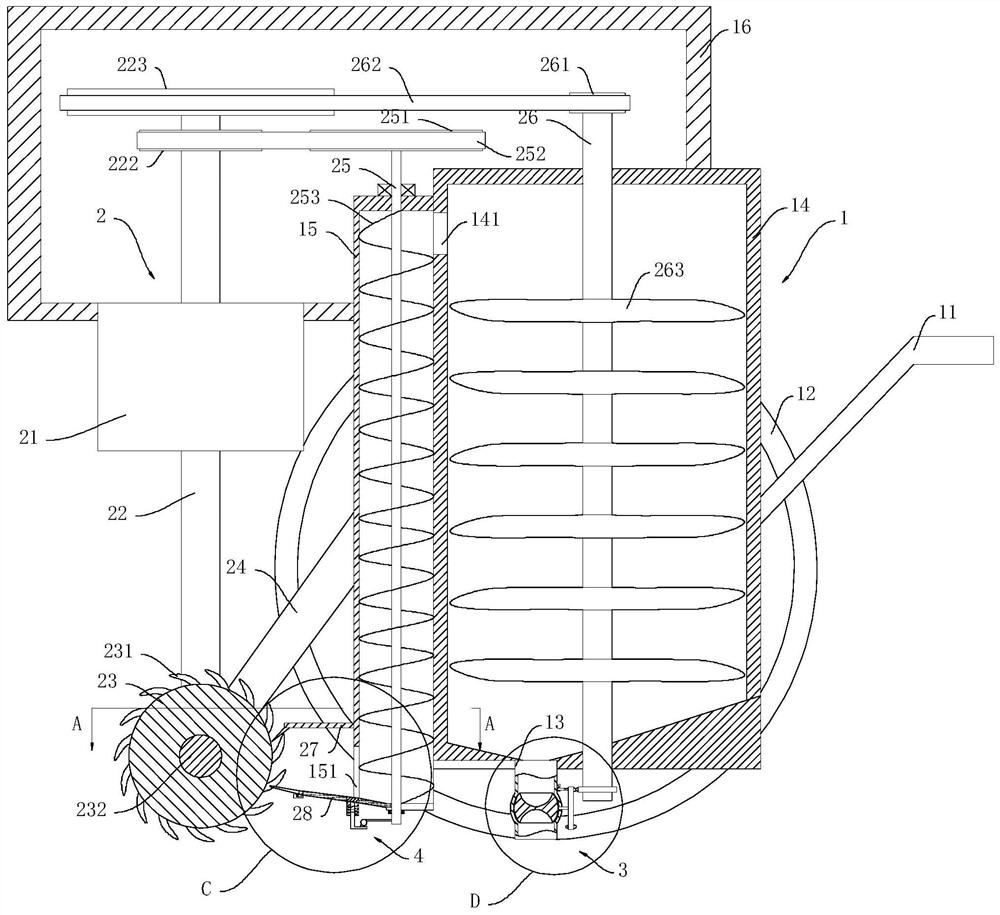

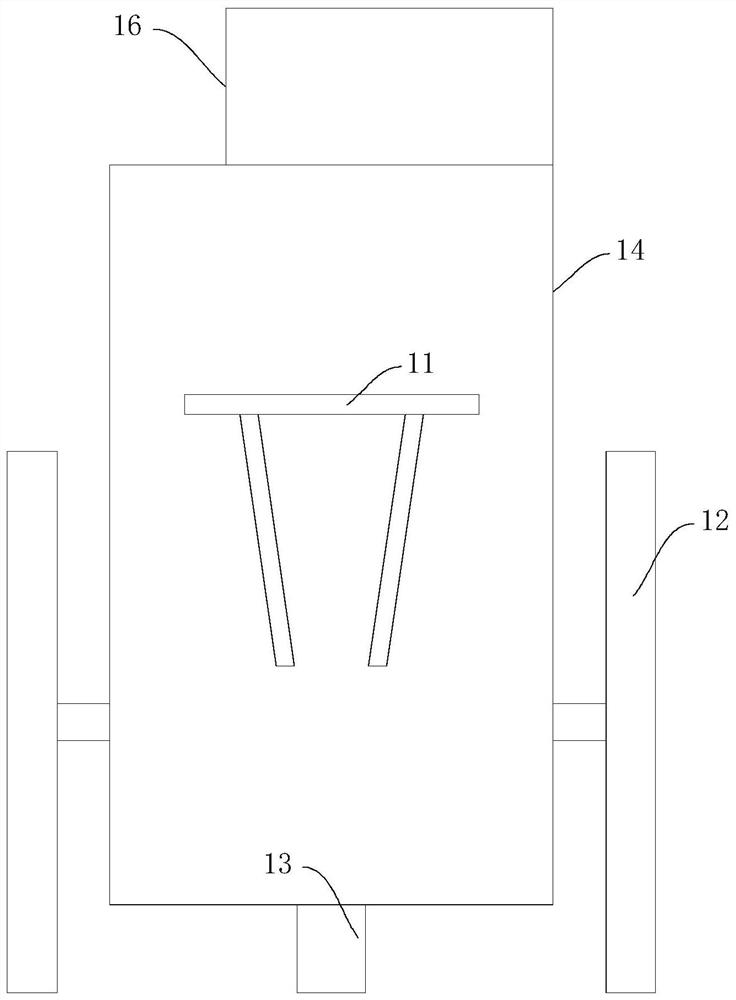

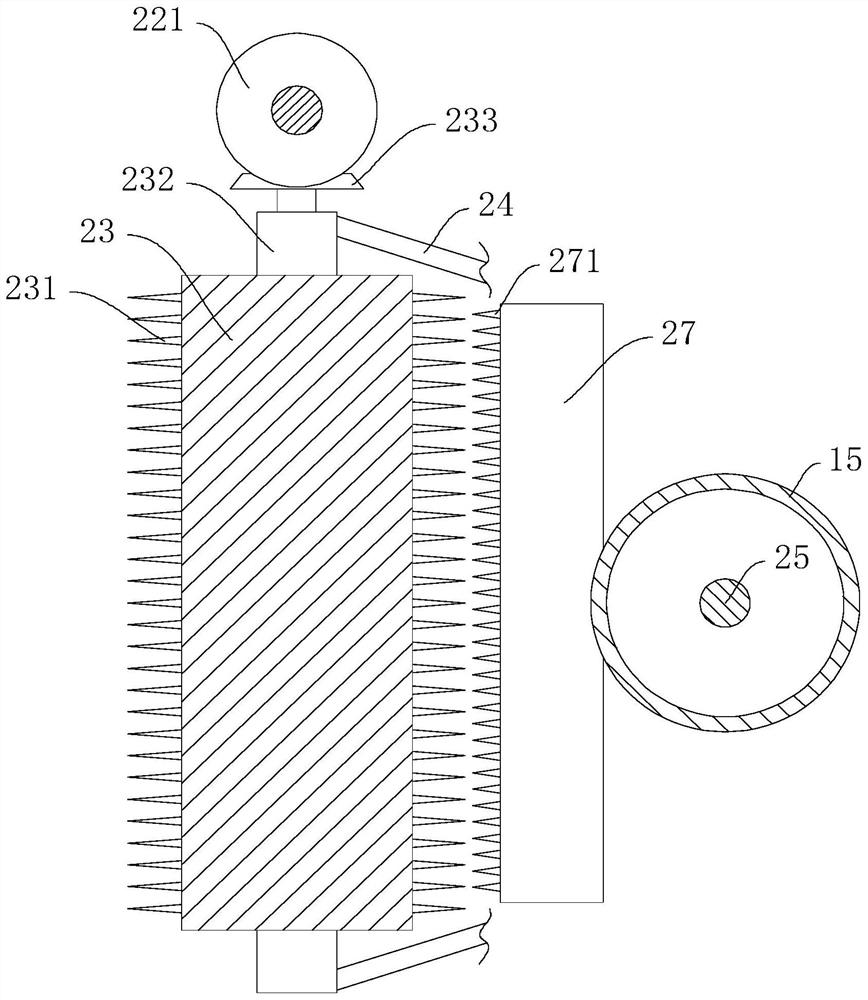

[0028] Such as Figure 1 to Figure 8 As shown, a kind of agricultural stubble processing device provided by the embodiment of the present invention includes a storage device 1 and a drive device 2, and the storage device 1 includes a handle 11, wheels 12, discharge pipe 13, storage barrel 14, and feeding barrel 15 And the housing 16, two wheels 12, the two wheels 12 are respectively rotatably connected to both sides of the material storage barrel 14, the handle 11 and the feeding barrel 15 are respectively fixedly connected to the other two sides of the material storage barrel 14, The side wall of the upper end of the material storage barrel 14 is provided with a feed inlet 141, and the feed inlet 141 penetrates into the material storage barrel 14 and the feed barrel 15 respectively, and the housing 16 is fixedly connected to the top of the material storage barrel 14, and the discharge pipe 13 is fixedly connected to the bottom of the storage tank 14, and the discharge pipe 13...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 1 to Figure 8 As shown, the bottom end of the storage tank 14 is provided with a blanking device 3, and the blanking device 3 includes a blanking ball 31, a first connecting rod 32, a rotating disk 33, a ring gear 34, a second connecting rod 35, a block 36 and The locking block 37 and the blanking ball 31 are rotatably arranged in the discharge pipe 13, the upper and lower ends of the blanking ball 31 are provided with a spherical blanking chamber 311, and one end of the first connecting rod 32 is connected to the discharge pipe 13 The inside is fixedly connected with the blanking ball 31, and the other end of the first connecting rod 32 is connected to the middle of the turntable 33 by transmission, and the two sides of the turntable 33 are fixedly connected with the first gear teeth 331 and the second gear teeth respectively along the circumferential direction. 332, the ring gear 34 is fixedly connected to the second drive sh...

Embodiment 3

[0038] On the basis of embodiment 1 or 2, such as Figure 1 to Figure 8 As shown, the lower end of the feeding bucket 15 is provided with a knocking device 4, and the knocking device 4 includes a housing case 41, an L-shaped rod 43, a third spring 44, a first impact ball 45, a second impact ball 46 and a third connection The rod 47 and the storage case 41 are fixedly connected to the lower surface of the second support plate 28. The storage case 41 is provided with a storage chamber 42. One end of the L-shaped rod 43 is slidably connected in the storage chamber 42, and the other end is fixedly connected The first impact ball 45, the third spring 44 is sleeved on one end of the L-shaped rod 43 located in the storage cavity 42, one end of the third spring 44 is fixedly connected to the L-shaped rod 43, and the other end is fixedly connected to the storage case 41 On the inner wall of the third connecting rod 47, one end of the third connecting rod 47 is fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com