A drying mechanism for vegetable dehydration

A drying mechanism, vegetable dehydration technology, applied in application, food drying, food heat treatment and other directions, can solve the problem of uneven drying of leaves and leaves, and achieve the purpose of inhibiting bacterial reproduction, increasing elasticity and ductility, and promoting water evaporation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

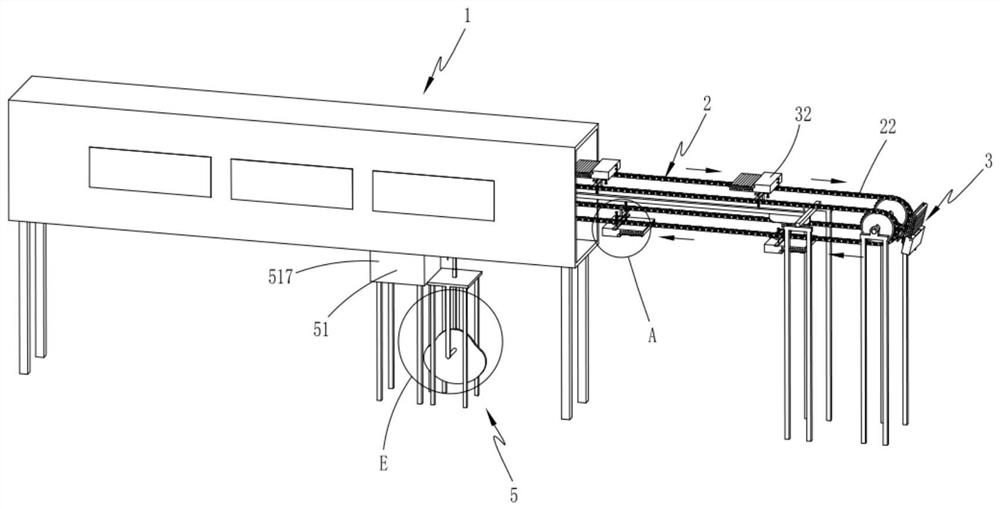

[0049] Such as Figure 1 to Figure 8 As shown, a drying mechanism for vegetable dehydration, including:

[0050] An oven 1, the oven 1 includes a preheating zone 11, a drying zone a12, a drying zone b13 and a cooling zone 14;

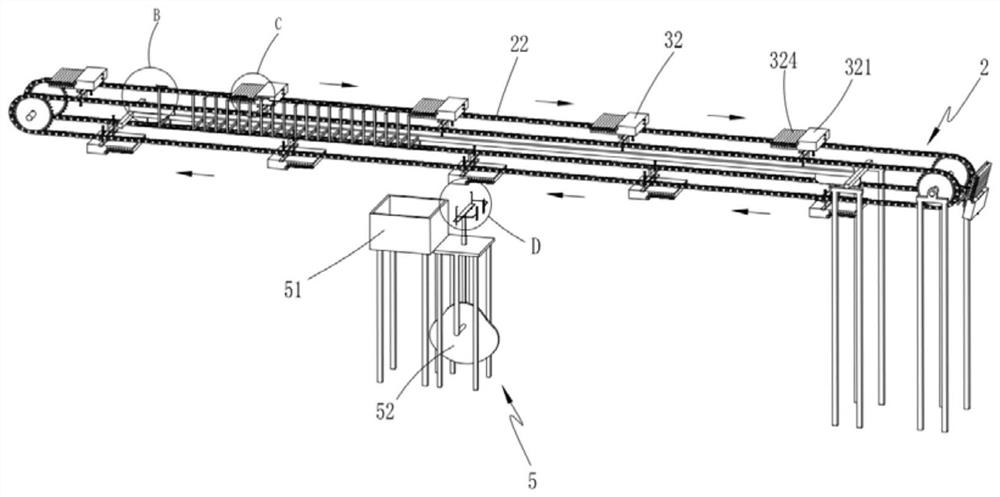

[0051] The conveying device 2, the conveying device 2 includes a conveying component b22 passing through the preheating zone 11, the drying zone a12, the drying zone b13 and the cooling zone 14 in sequence;

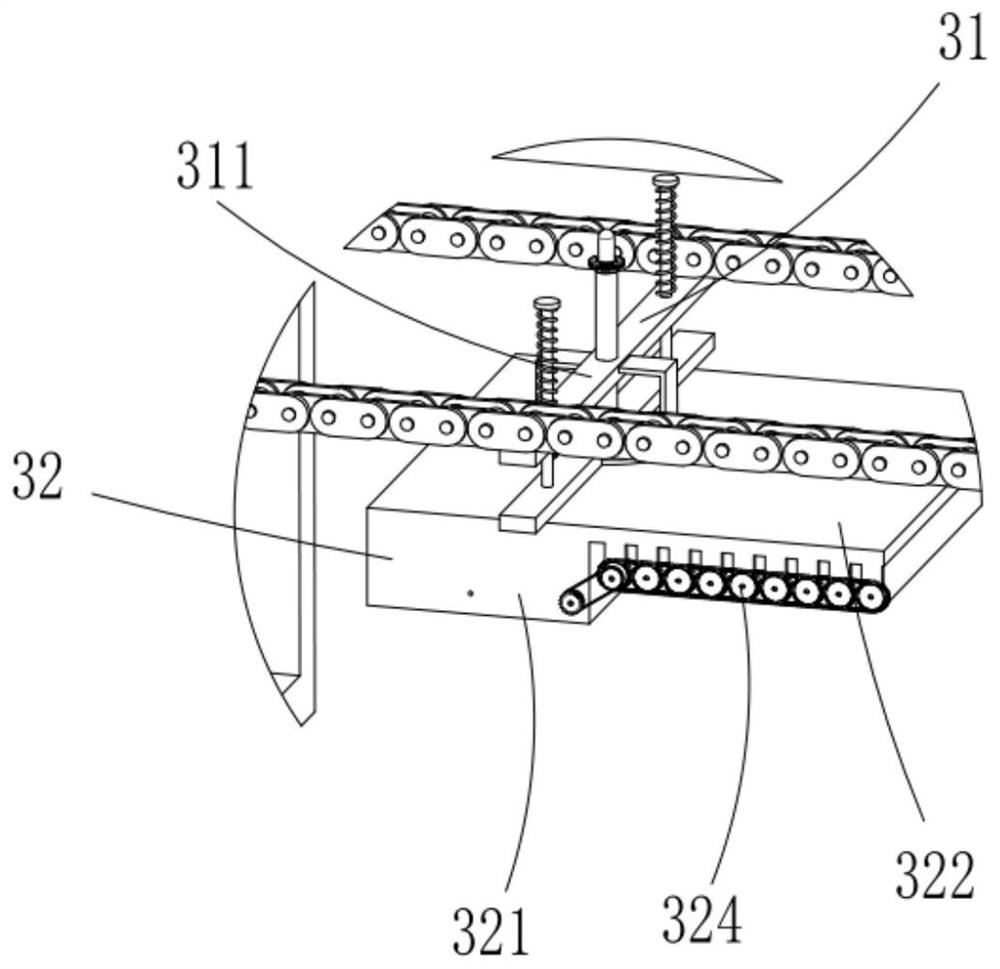

[0052] The feeding device 3, the feeding device 3 includes several sets of mounting assemblies 31 distributed on the rotary path array along the conveying assembly b22 and capable of rotating and moving up and down, and correspondingly installed below the mounting assembly 31 and following the The material receiving assembly 32 of the movement of the mounting assembly 31;

[0053] The material receiving assembly 32 includes a heat insulation box 321 and a drying table 322 arranged front and back along the conveying direction of the conveying asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com