Whitening and freckle-removing essence as well as preparation method thereof

A technology for whitening and removing freckle and essence, which is applied in the field of whitening and freckle removing essence and its preparation, can solve the problems of unsatisfactory combination of raw materials and preparation method, failure to achieve whitening and freckle removal effect, poor product stability, etc., and achieves increased antioxidant capacity. , Improve the effect of whitening and freckle removal, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

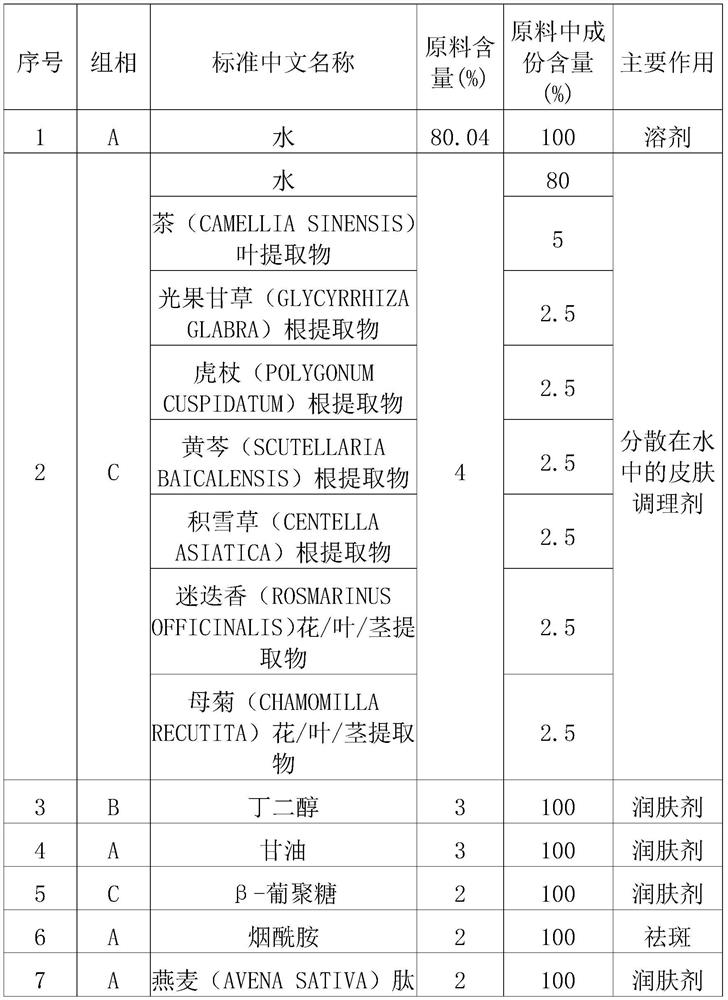

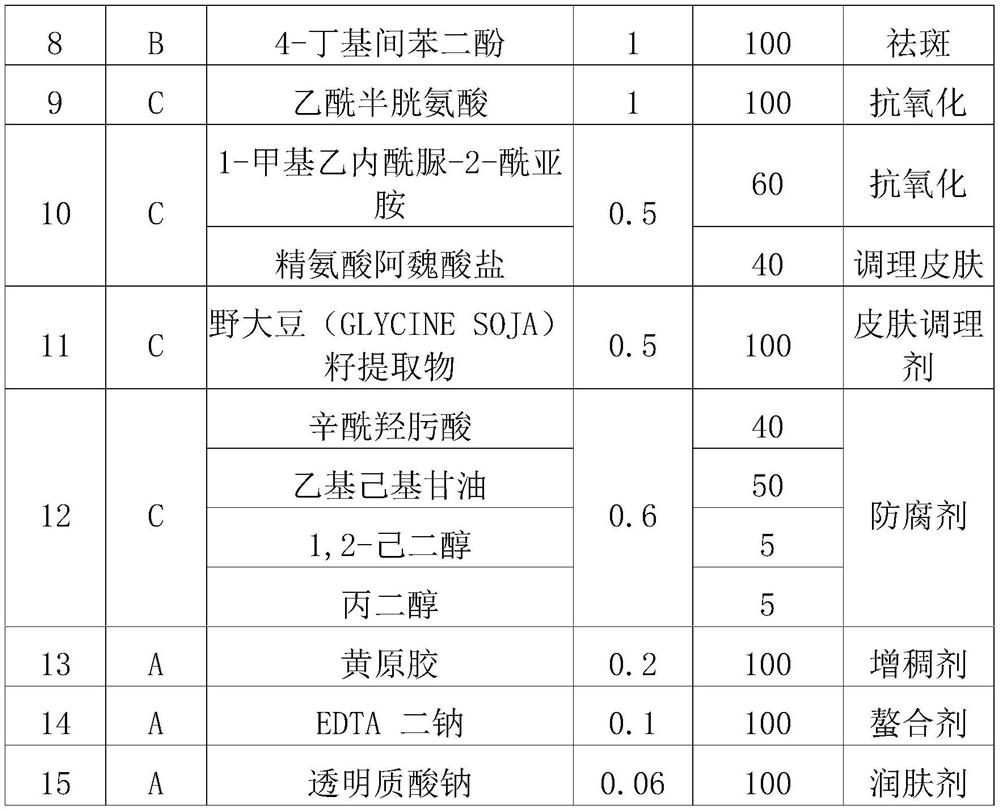

[0025] The raw materials used in this embodiment and their content, function, and phase of the mixing process are shown in Table 1 below.

[0026] The raw material of table 1 embodiment 1

[0027]

[0028]

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] 1. Add the raw materials of phase A into the water phase pot, stir and heat up to 80°C, stir well, keep warm for later use;

[0031] 2. First pump the raw materials of phase A into the vacuum emulsification mixer, continue to stir, vacuumize, and keep the temperature constant for 10 minutes;

[0032] 3. When the temperature is lowered to 45°C, add the raw materials of Phase B and Phase C, and stir well;

[0033] 4. When the temperature is lowered to 38°C, discharge and stand still;

[0034] 5. After passing the inspection, filling, packaging, and coding;

[0035] 6. After passing the sampling inspection, it will be put into storage.

Embodiment 2

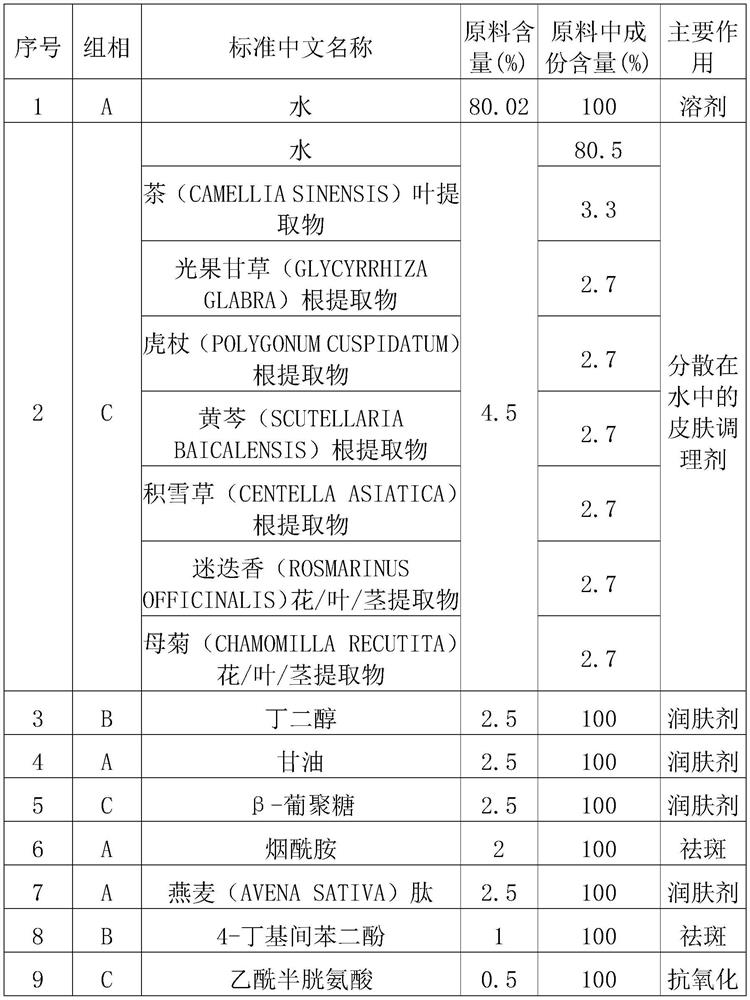

[0037] The raw materials used in this embodiment and their content, function, and phase of the mixing process are shown in Table 2 below.

[0038] The raw material of table 2 embodiment 2

[0039]

[0040]

[0041] The preparation method of the present embodiment comprises the following steps:

[0042] 1. Add the raw materials of phase A into the water phase pot, stir and heat up to 85°C, stir well, keep warm for later use;

[0043] 2. First pump the raw materials of phase A into the vacuum emulsification mixer, continue to stir, vacuumize, and keep the temperature for 5 minutes;

[0044] 3. When the temperature is lowered to 40°C, add the raw materials of Phase B and Phase C, and stir well;

[0045] 4. When the temperature is lowered to 35°C, discharge the material and let it stand still;

[0046] 5. After passing the inspection, filling, packaging, and coding;

[0047] 6. After passing the sampling inspection, it will be put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com