Hard coating film and window and image display device using same

A hard-coating and hard-coating technology, used in identification devices, biocide-containing paints, coatings, etc., can solve the problems of unsuitability for mass production, the antifouling property cannot reach flexible image display devices, and the time is long. The effect of excellent antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

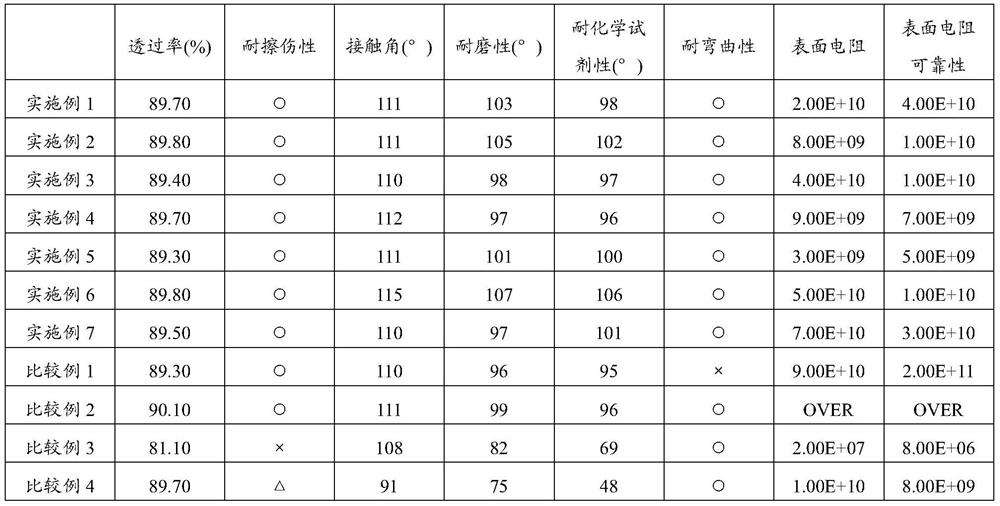

[0125] 20% by weight of 6-functional urethane acrylate (UA-1100H, New Nakamura Company), 25% by weight of dendritic acrylate (MIRAMER SP1106, Miwon Company), 17% by weight of conductive polymer (SAS- F16, 1% solid content, Shin-Etsu Polymer Co., Ltd.), 3% by weight of 1-hydroxycyclohexyl phenyl ketone, 0.3% by weight of fluorine-based UV-curable functional group-containing compound (KY-1203, 20% solid content, Shin-Etsu company) and 34.7% by weight of methyl ethyl ketone were blended with a mixer and filtered through a filter made of PP to produce a hard coating composition.

manufacture example 2

[0127] 15% by weight of 6-functional urethane acrylate (UA-1100H, New Nakamura Company), 30% by weight of dendritic acrylate (MIRAMER SP1106, Miwon Company), 17% by weight of conductive polymer (SAS- F16, 1% solid content, Shin-Etsu Polymer Co., Ltd.), 3% by weight of 1-hydroxycyclohexyl phenyl ketone, 0.3% by weight of fluorine-based UV-curable functional group-containing compound (KY-1203, 20% solid content, Shin-Etsu company) and 34.7% by weight of methyl ethyl ketone were blended with a mixer and filtered through a filter made of PP to produce a hard coating composition.

manufacture example 3

[0129] 30% by weight of 6-functional urethane acrylate (UA-1100H, New Nakamura Company), 15% by weight of dendritic acrylate (MIRAMER SP1106, Miwon Company), 17% by weight of conductive polymer (SAS- F16, 1% solid content, Shin-Etsu Polymer Co., Ltd.), 3% by weight of 1-hydroxycyclohexyl phenyl ketone, 0.3% by weight of fluorine-based UV-curable functional group-containing compound (KY-1203, 20% solid content, Shin-Etsu company) and 34.7% by weight of methyl ethyl ketone were blended with a mixer and filtered through a filter made of PP to produce a hard coating composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com