A control module of an automotive electronic water pump

A technology of automotive electronics and control modules, applied in pump control, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as poor ambient temperature, high operating power, and impossibility, and achieve durable The effect of large ripple current, large discharge charge, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

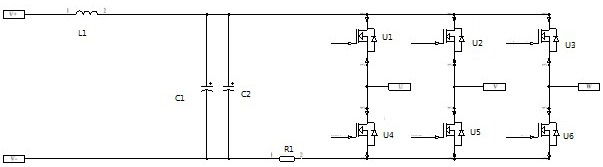

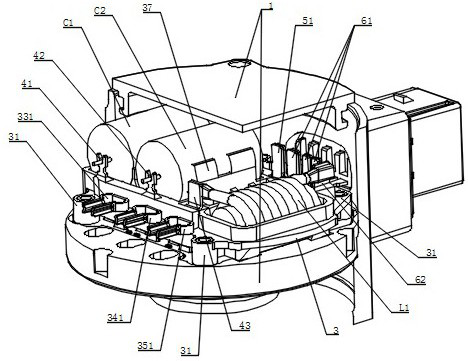

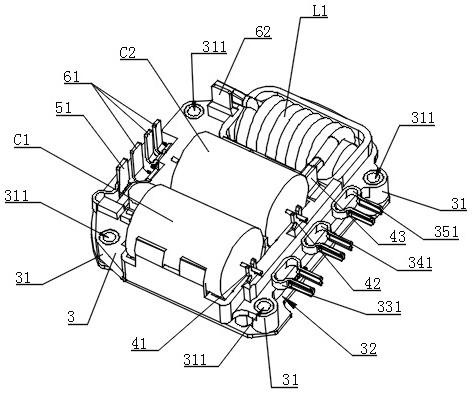

[0024] Embodiment one: if Figure 1 to Figure 6 As shown, a control module of an automotive electronic water pump includes a control cabin 1 and a circuit board 2 arranged in the control cabin 1, a main control module (not shown in the figure) and a rotation control module. The rotation control module includes a filter module and a drive signal The generating module, the filtering module is located between the external DC power supply (not shown in the figure) and the driving signal generating module, the main control module and the driving signal generating module are both arranged on the circuit substrate 2, and the main control module is used to control the driving signal generating module to generate three The three-phase drive signal is sent to the three-phase drive signal input terminal of the water pump stator (not shown in the figure). The three-phase drive signal input terminal of the water pump stator includes a U-phase signal connection terminal (not shown in the fig...

Embodiment 2

[0029] Embodiment two: if Figure 1 to Figure 5 As shown, the remaining parts are the same as the first embodiment, the difference is that the insulating mounting bracket 3 is fixedly provided with a first conductive copper strip (not shown in the figure), a second conductive copper strip (not shown in the figure) and The third conductive copper strip (not shown in the figure), the inside of the insulating mounting bracket 3 is provided with a first installation groove (not shown in the figure) for installing the first conductive copper strip, and a second installation groove for installing the second conductive copper strip (not shown in the figure) and the third installation slot (not shown in the figure) for installing the third conductive copper strip, the other end of the inductor L, the positive pole of the first axial lead capacitor C1, and the positive pole of the second axial lead capacitor C2 , the drain of the first NMOS transistor U1, the drain of the second NMOS t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com