Visual tactile automobile high-reflective surface three-dimensional shape measurement method and system

A three-dimensional topography and measurement system technology, applied in the field of three-dimensional measurement, can solve problems such as large-scale data holes, increase hardware complexity, and affect measurement results, and achieve the effect of improving measurability, non-destructive measurement methods, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

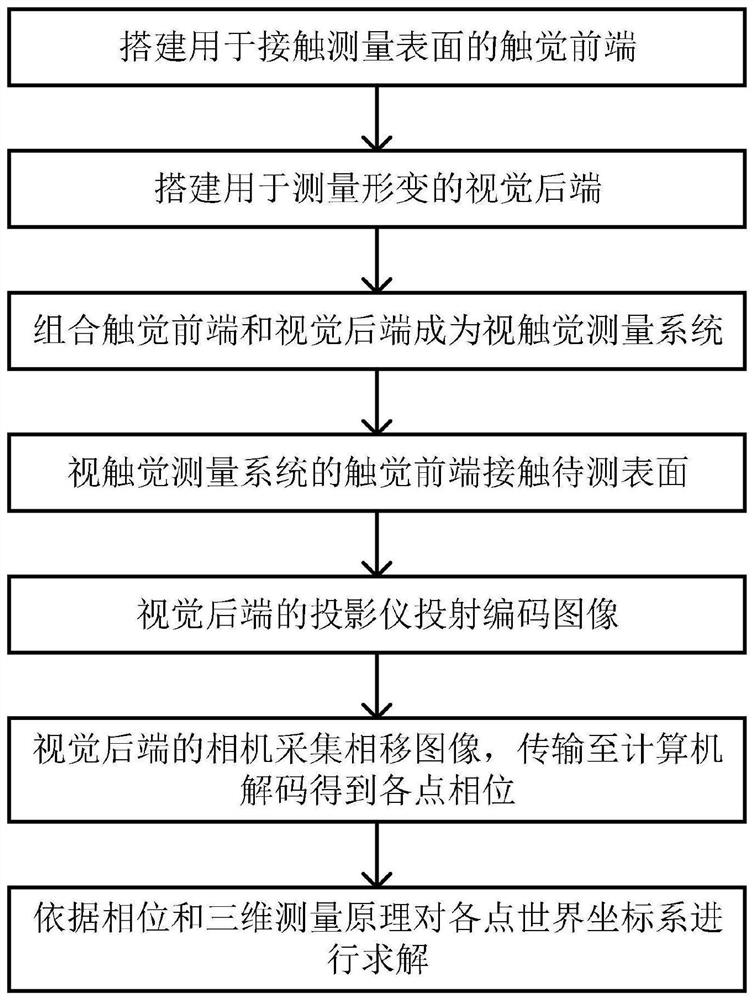

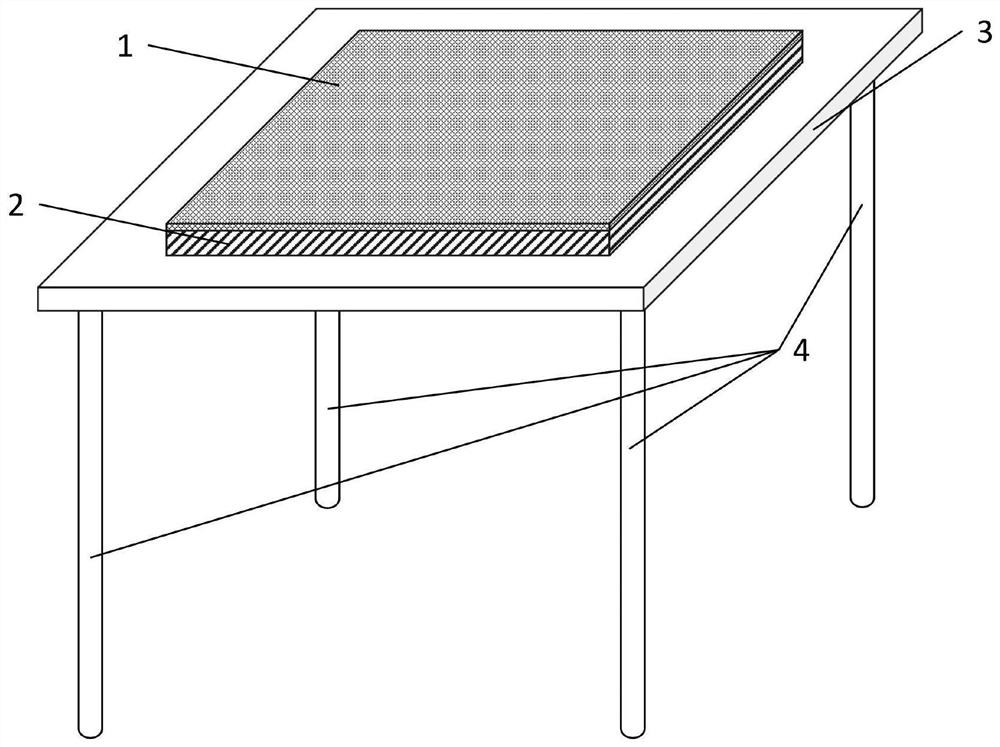

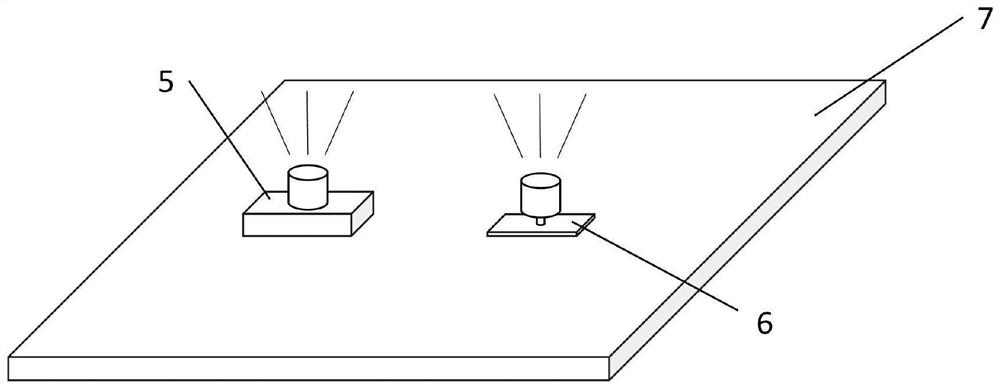

[0029] The present invention proposes a method and system for measuring the three-dimensional topography of a highly reflective surface of a visual and tactile automobile. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples serve to illustrate the present invention, but do not limit the scope of the present invention.

[0030] The present invention proposes a method for measuring the three-dimensional shape of the highly reflective surface of a visual and tactile automobile. The highly reflective surface of the automobile referred to in the present invention refers to the surface of the vehicle body after spraying, the mold after polishing, etc. in the automobile industry. This type of surface has high The reflectivity makes the light intensity saturation phenomenon occur when the camera directly collects the surface image (that is, in the captured image, the pixels in som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com