Design structure for electrostatic protection of broken code display screen

A technology of electrostatic protection and design structure, applied in the field of display information, can solve the problems of the existence of self-built induced electric field, the accumulation of static electricity, and the inability to completely solve the problems, so as to achieve the maturity of process design and production technology, and solve the problem of display pattern disorder. , The effect of improving the ability of anti-static interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

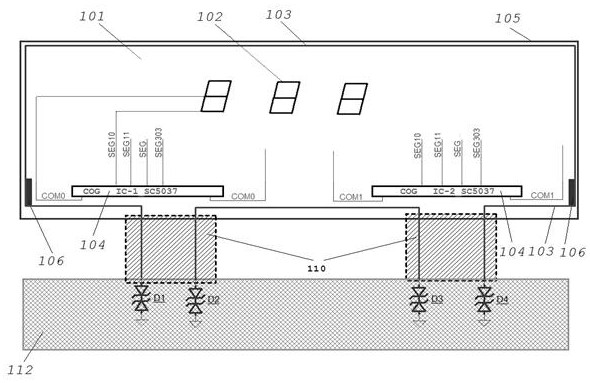

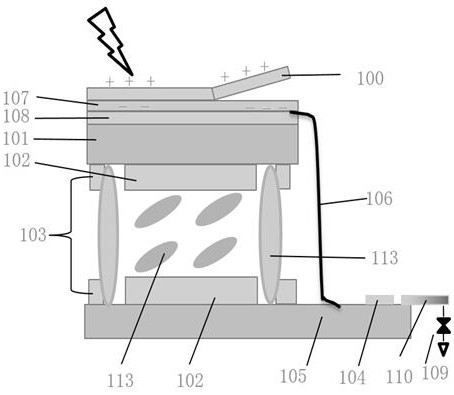

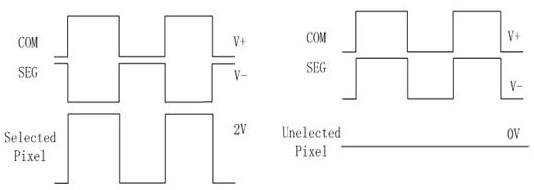

[0033] see Figure 1-Figure 4 , the present invention provides a design structure for electrostatic protection of code-breaking display screens: including anti-static adsorption film 100, polarized glass 107, upper ITO glass 101, lower ITO glass 105, and the top surface of the upper ITO glass covers the entire piece of ITO conductive film 108 , the edge of the lower surface of the upper ITO glass is designed with an ITO static ring shielding ground 103, liquid crystal molecules LC 113, the inner film wiring of the upper and lower ITO glass corresponds to the working display electrode section 102, and the working electrode wiring is divided into SEG-electrodes distributed on the lower ITO glass On the upper surface, the COM-ITO electrodes are distributed on the lower surface of the upper ITO glass. The SEG and COM electrode wirings are output by the driver chip 104. The edge of the top surface of the lower ITO glass is designed with an ITO anti-static shielding loop 103. The upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com